Equipment and method for on-site sampling in soft soil areas for survey work

An on-site sampling and regional technology, which is applied in the field of foundation soil survey, sampling device, infrastructure engineering, etc., can solve the problems of increased project cost, heavy weight, and extended project period, so as to ensure reliability and speed of installation Fast, actionable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

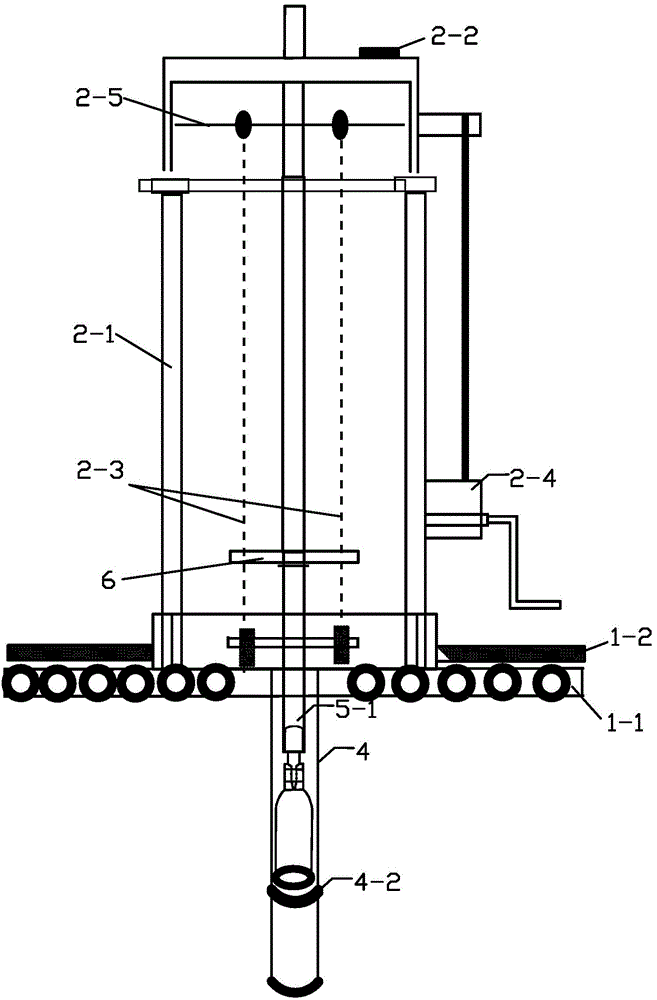

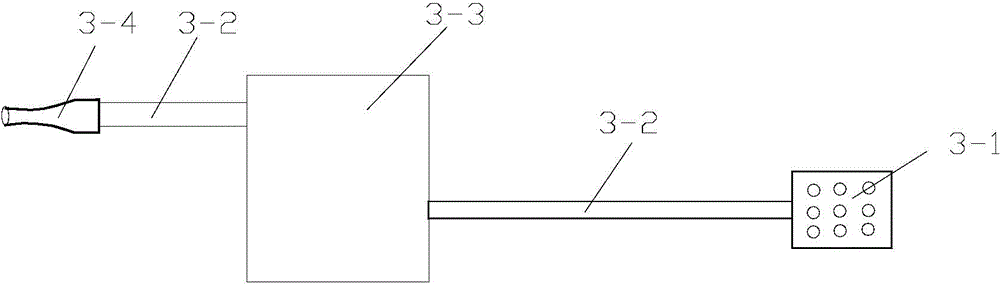

[0041] See Figure 1 to Figure 8 , a device for on-site sampling of soft soil areas for survey work, comprising a bearing platform, a sampling power system, a sampling device, a hole-forming device, a hole-protecting device, a generator and a transport device.

[0042] The carrying platform includes a chassis 1-1, a pedal 1-2 and counter pressure weights (not shown in the figure). The chassis 1-1 adopts a lattice structure formed by longitudinal welded pipes and transverse welded pipes. Between the longitudinal welded pipes and the transverse welded pipes between the snap-fit connection,

[0043] Pedals 1-2 are laid on both sides of the chassis 1-1 to form a working platform, and anti-pressure weights are placed on the pedals 1-2 and / or th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com