Hole depth detection device of automobile brake system bracket

A car brake and depth technology, applied in the direction of mechanical depth measurement, etc., can solve the problems of high production failure rate, brake bracket production failure rate, low production efficiency, etc., to solve the high production failure rate, ensure high quality and high efficiency The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the examples.

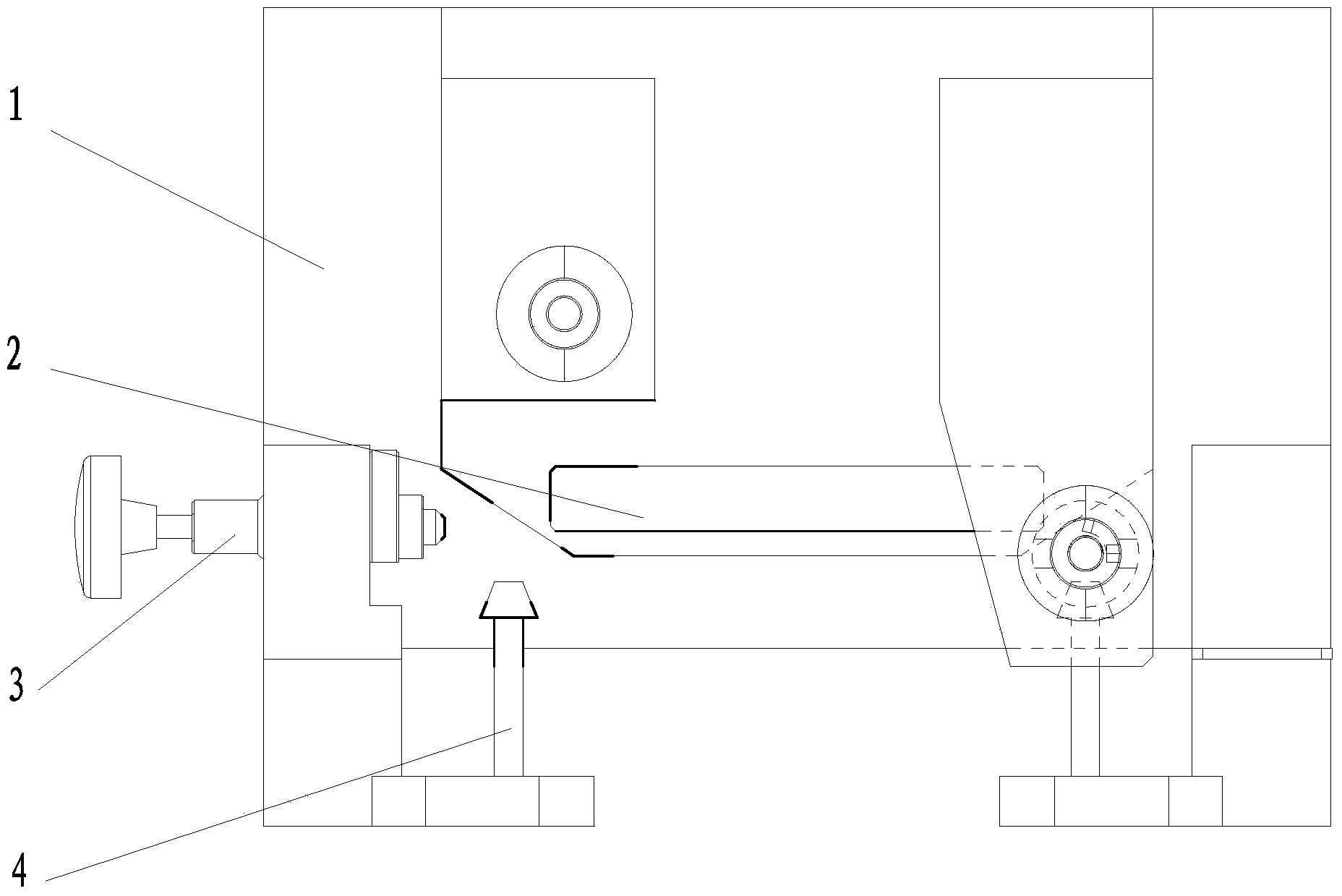

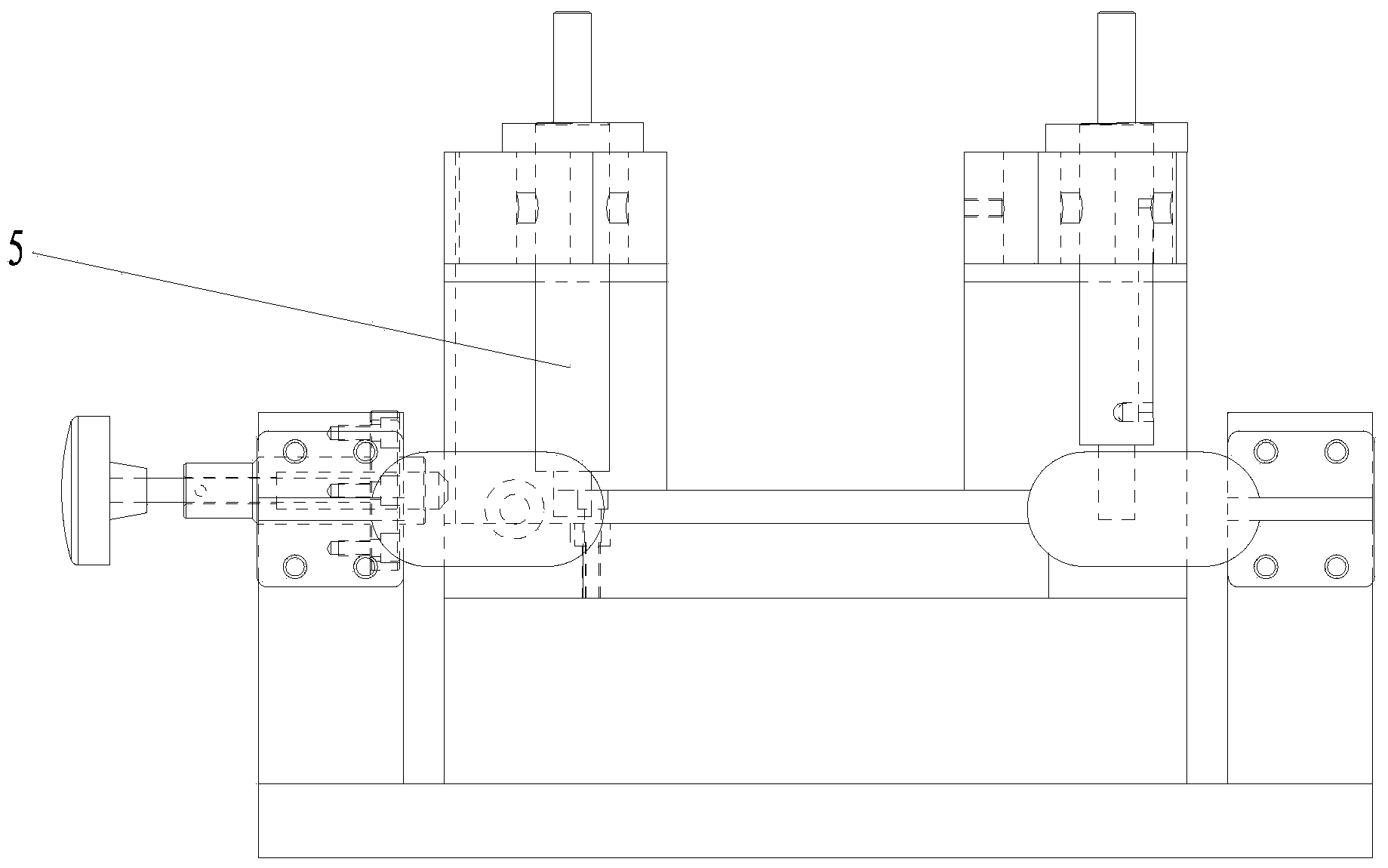

[0014] A tool for measuring the depth of a bracket hole of an automobile brake system, comprising a clamping and positioning part and a detection part; the clamping and positioning part includes a bottom plate 1, a positioning plate 2, an X-direction jacking pin 3, and a Y-direction positioning column 4; the detection part includes a detection column 5. A positioning plate 2, a Y-direction positioning column 4 and an X-direction tightening pin 3 are installed on the bottom plate 1 for positioning and clamping the detected workpiece. The detection column 5 corresponds to the position of the workpiece hole to be detected. It can be inserted deep down into the detection hole, and its upper end is engraved with a scale range to confirm whether the depth of the hole is qualified. During detection, the detection column is in the middle of the tolerance section.

[0015] When testing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com