Connecting device for insulating operating bar

A technology of insulating operating rods and connecting devices, which is applied in the direction of cable installation devices, cable installations, electrical components, etc., can solve the problems of single function of the operating rod and the inability to change the length of the operating rod, so as to avoid single function, improve repair time, Linking Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

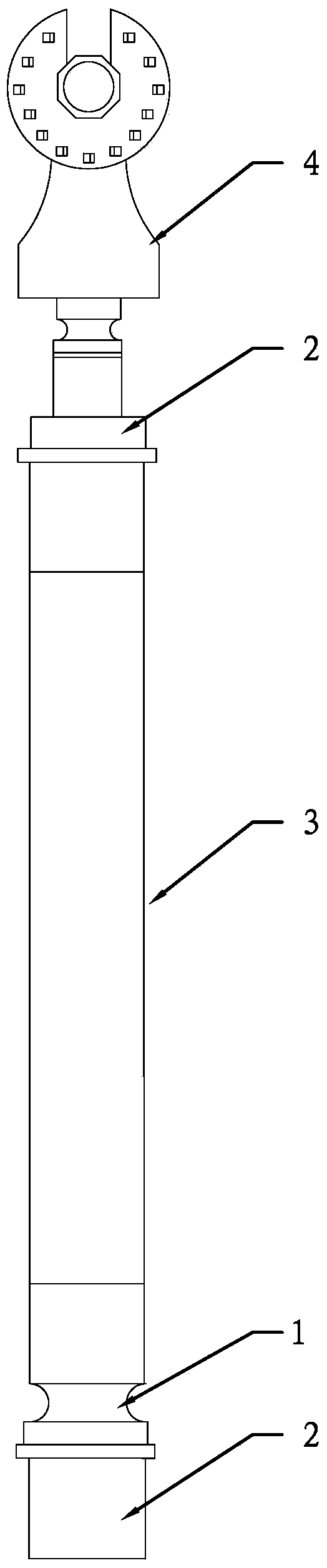

[0026] Specific implementation mode one: see Figures 1 to 9 Describe this embodiment, an insulated operating rod connection device described in this embodiment, which includes a spline type end connection part 1, two spring type end connection parts 2, an insulating operation rod 3 and a gear type The terminal connection part 4; the insulating operating rod 3 is a cylindrical structure,

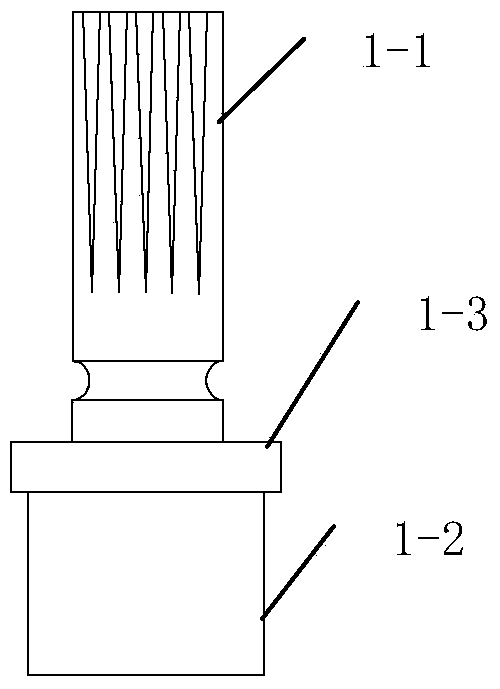

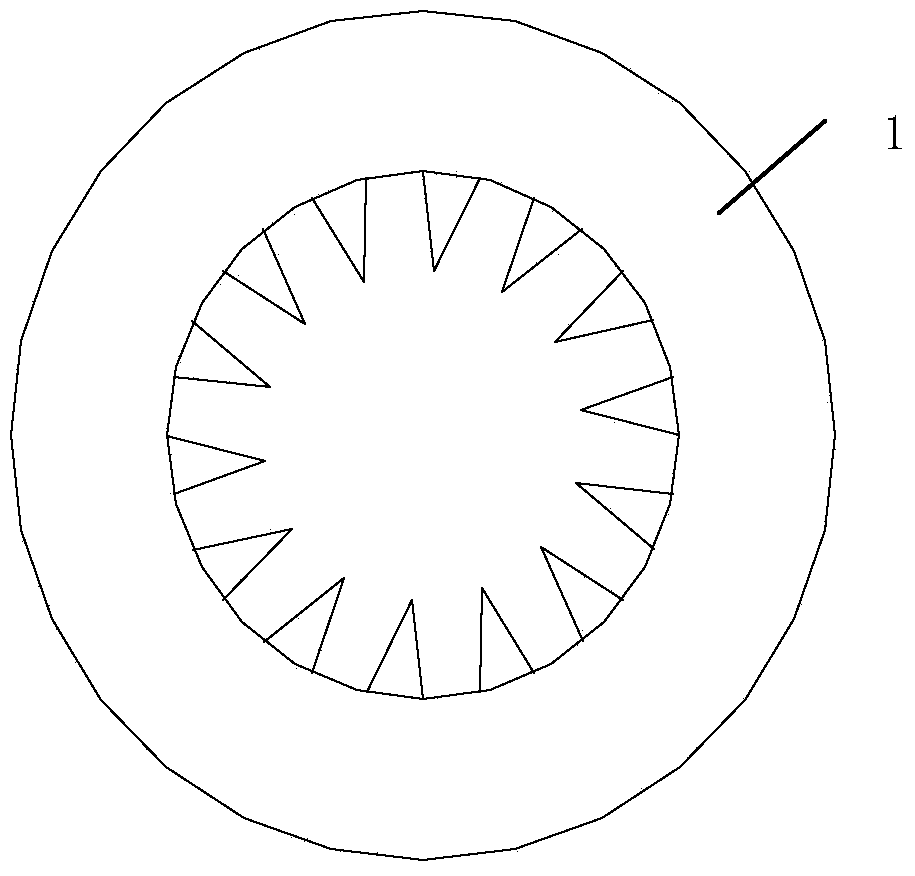

[0027] The splined end connection part 1 includes a first spline shaft 1-1 and a connecting shaft 1-2, the first spline shaft 1-1 and the connecting shaft 1-2 are coaxially connected and made into one structure, the diameter of the first splined shaft 1-1 is smaller than the diameter of the connecting shaft 1-2, and one end of the connecting shaft 1-2 connected to the first splined shaft 1-1 is provided with a shoulder 1-3, and the connecting shaft 1- The other end of 2 is inserted into one end of the insulating operating rod 3, and is fixedly connected with the insulating operating rod 3, ...

specific Embodiment approach 2

[0036] Specific implementation mode two: see Figures 1 to 9 This embodiment is described. The difference between this embodiment and the connecting device for an insulating operating rod described in Embodiment 1 is that the radial section of the boss 4 - 4 is rectangular.

specific Embodiment approach 3

[0037] Specific implementation mode three: see Figures 1 to 10 This embodiment is described. The difference between this embodiment and the connection device for an insulated operating rod described in Embodiment 1 or Embodiment 2 is that the surface of the cylindrical casing 2-6 is formed into a scale-like grid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com