A modular vertical greening device and its manufacturing method

A technology of vertical greening and manufacturing method, applied in watering devices, botanical equipment and methods, container cultivation, etc., can solve the problems of large destructive force of building walls, uneven distribution of scope, single landscape effect, etc., and achieve environmental friendliness. , Simple construction, the effect of widening the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

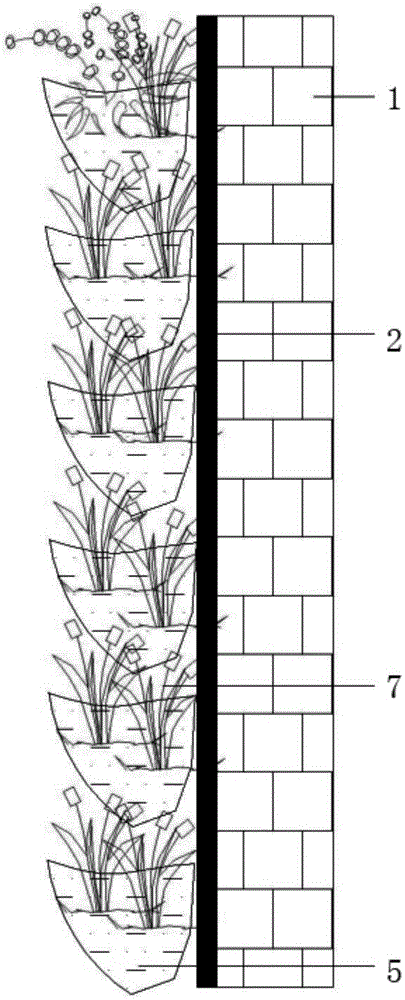

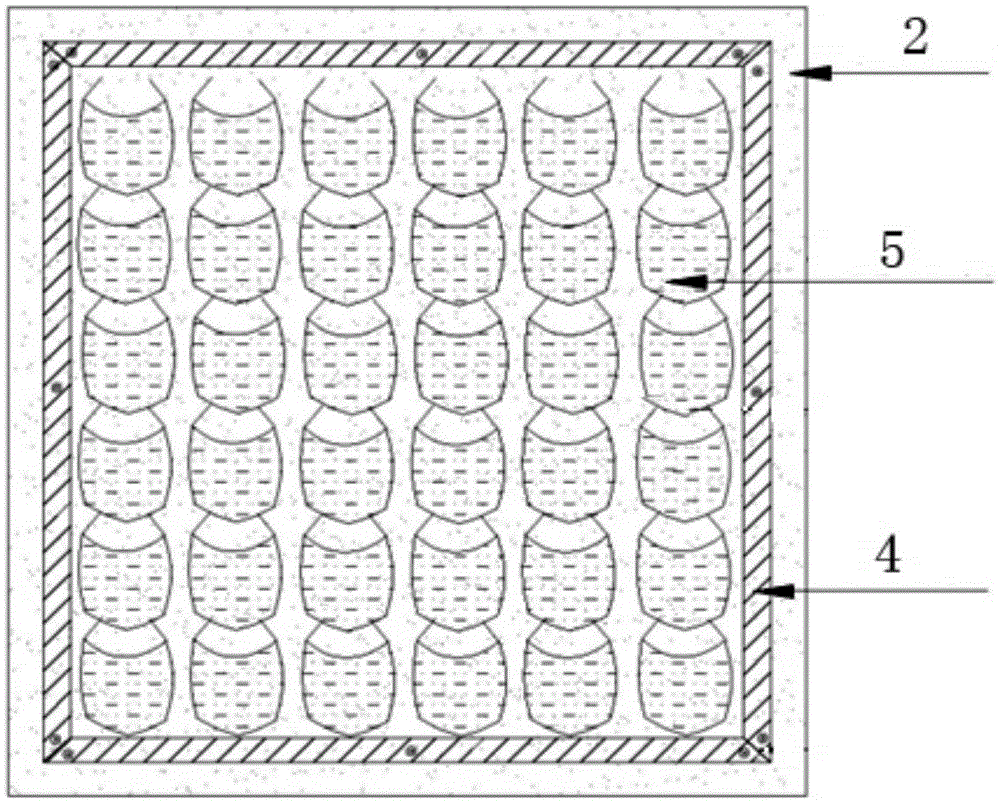

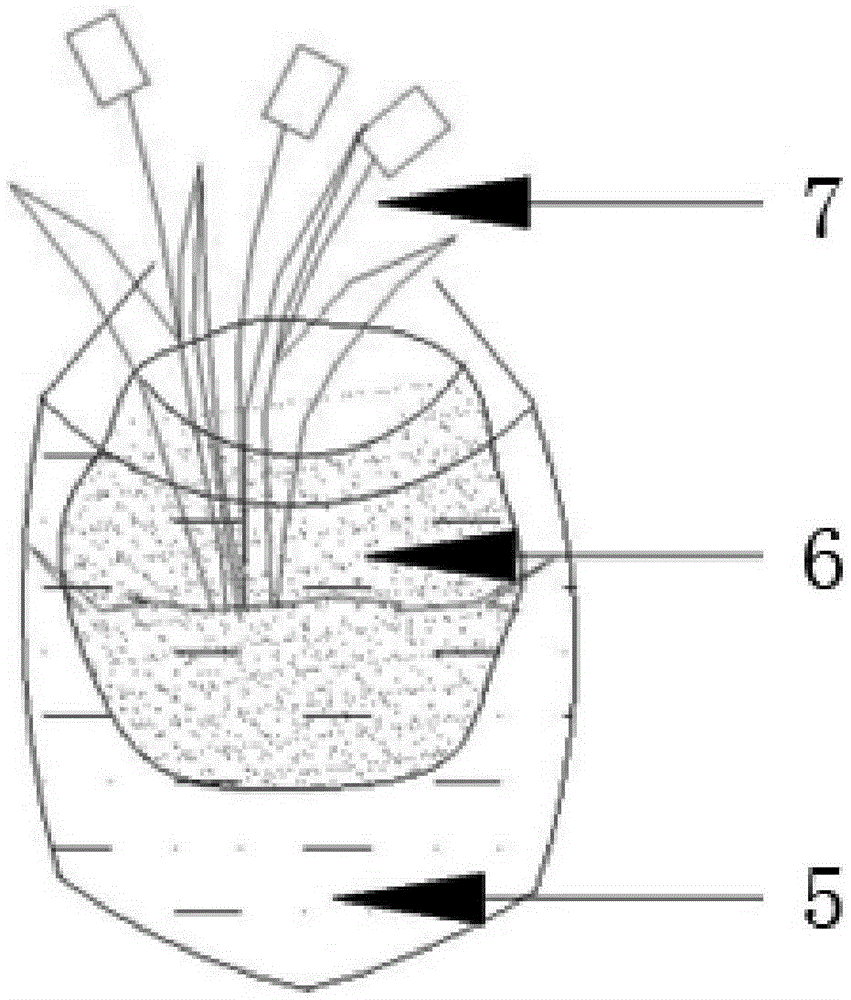

[0030] The present invention provides a modular vertical greening device and a manufacturing method thereof. The modular vertical greening device includes an anti-seepage wall 1 and a vertical greening module installed on the anti-seepage wall 1 through an anti-seepage geomembrane 2 Unit 3; the anti-seepage wall 1 is made by fixing the anti-seepage geomembrane 2 on the wall with super glue, so as to ensure that the anti-seepage geomembrane 2 will not fall off; the vertical greening module unit 3 is fixed on the anti-seepage On the seepage geomembrane 2, the edge or part of the anti-seepage geomembrane 2 is installed on the anti-seepage wall 1 through the plate 4. The material of the plate 4 can be steel plate or aluminum alloy plate to ensure that the plate 4 strength, fully play the role of fixing the anti-seepage geo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com