Slope protection brick and brick making mold

A technology for slope protection bricks and molds, which is applied in the directions of manufacturing tools, auxiliary parts of molds, botanical equipment and methods, etc., can solve the problems of difficult filling and compaction of slope protection bricks, and achieves large green space, less material consumption, and economical effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

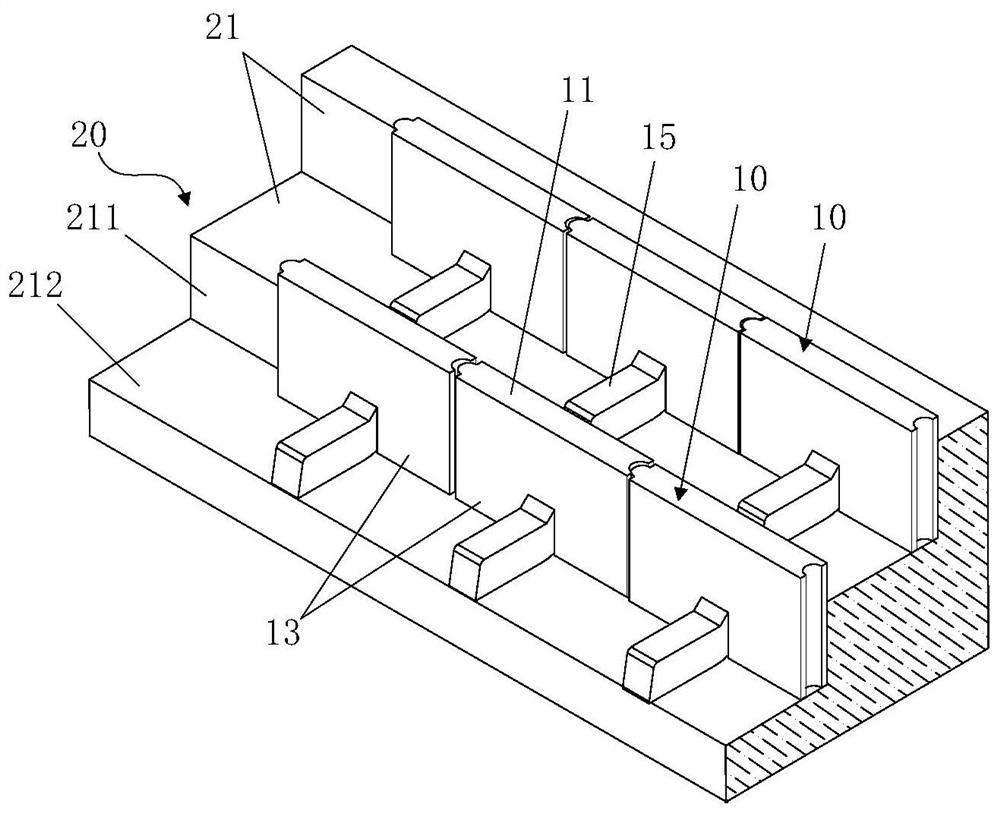

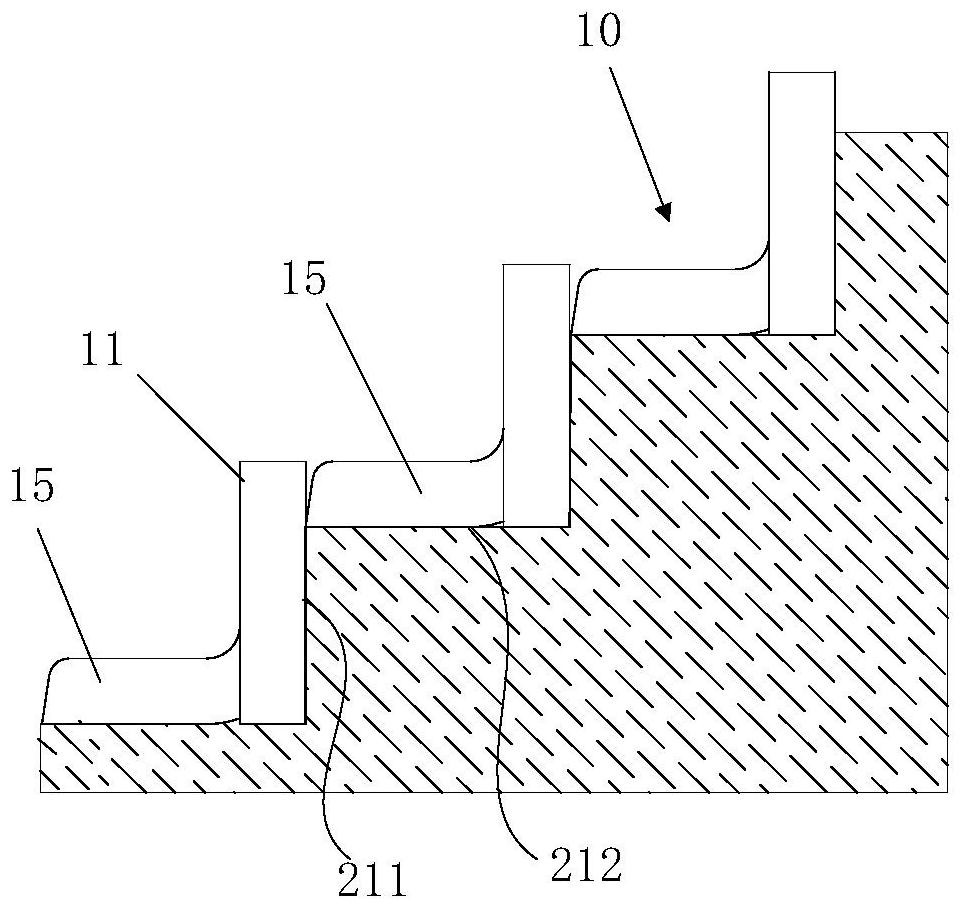

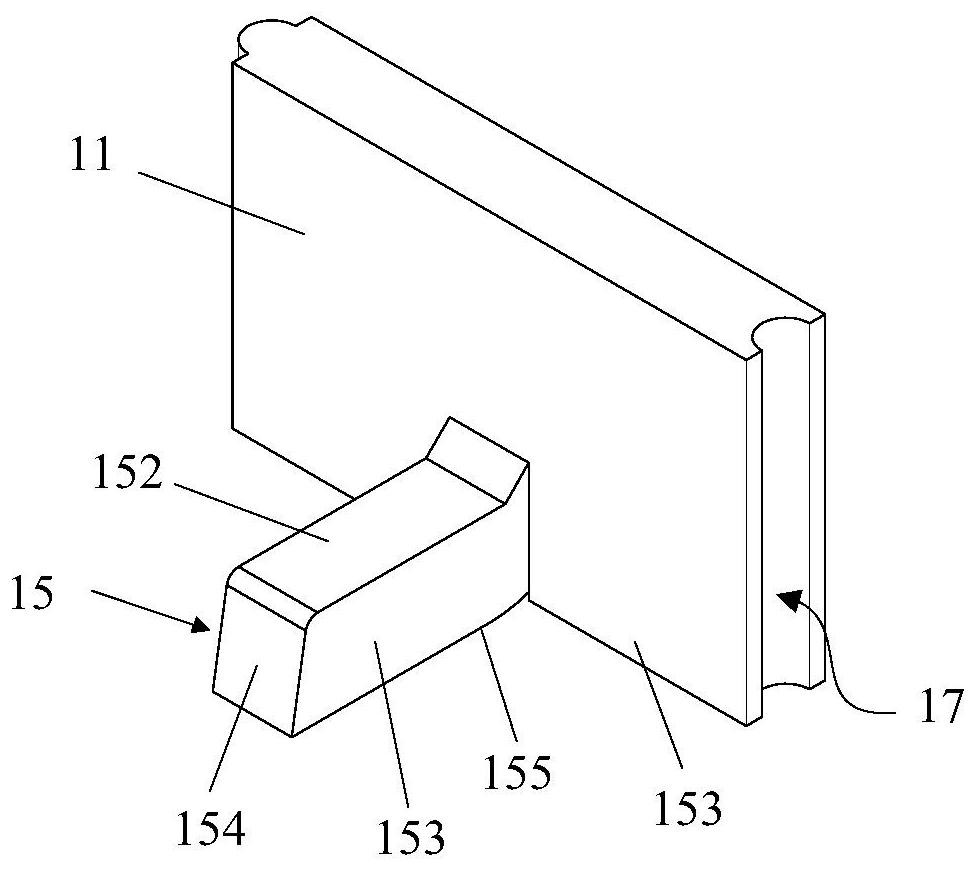

[0069] like image 3 and Figure 4 As shown, the slope protection brick of this embodiment has one cantilever 15 , which is centrally arranged in the longitudinal direction of the vertical earth retaining plate 11 , and two supporting feet 13 , which are symmetrically arranged on the left and right sides of the cantilever 15 .

[0070] The smooth transition surface 151 of the cantilever is an arc-shaped smooth surface.

[0071] The left and right sides of the slope protection brick 10 are the mortise and tenon interlocking structure 17, that is, the left side is a tenon 171 with a semicircular cross-section, the right side is a semicircular tenon groove 172, and the tenon and tenon of two adjacent slope protection bricks The grooves are butted together to form a mortise and tenon interlocking structure. The tenon and tenon groove of the mortise and tenon interlocking structure may also have cross-sectional shapes such as rectangle, dovetail, half tenon and half groove.

no. 2 example

[0073] like Figure 5 and Image 6 As shown, the difference between the slope protection brick of this embodiment and the first embodiment is that there is a distance L1 between the support foot 13 and the cantilever 15, and the spacing space allows the core-pulling mold 33 to be inserted horizontally, forming the arc transition surface 151 of the cantilever. and the side 153, the core-pulling die 33 is demolded first in the direction away from the vertical retaining plate horizontally (horizontal direction for short) during demolding.

no. 3 example

[0075] like Figure 7 , Figure 8 and Figure 9 As shown, the difference between the slope protection brick of this embodiment and the second embodiment is that there are side transition surfaces 156 between the two sides of the cantilever root and the vertical earth retaining plate, and the side transition surfaces 156 are formed by the core-pulling mold 33. The function is to smooth the filling when the cantilever is filled. There is an upper transition surface 157 between the upper surface 152 of the cantilever and the vertical earth retaining plate 11, and the function of the upper transition surface is to smoothly fill the cantilever during filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com