Cherry pitter

A cherry and pitting needle technology, applied in the field of cherry pitting machine, can solve the problems of low work efficiency, environmental pollution, short storage time, etc., and achieve the effect of convenient operation, high efficiency and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

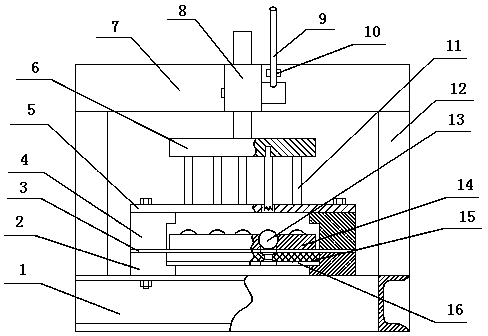

[0010] As an embodiment of the present invention, such as figure 1 As shown, a cherry pitting machine includes an upper fixed seat 7, a pitting device and a lower fixed seat 1, the upper fixed seat 7 is fixedly connected to the top of the lower fixed seat 1 through a support frame 12, and the support frame 12 is provided with a triangular reinforcement Ribs improve the strength of the present invention, preferably, triangular reinforcing ribs are arranged between the support frame 12 and the lower fixing base 1 . The denucleating device includes a needle plate 6, the top surface of the needle plate 6 is movably connected to the lower surface of the upper holder 7 through a driving mechanism 8, and the driving mechanism 8 is provided with a pressing rod 9, and the driving mechanism is used to rotate the pressing rod 9 Converted to the up and down vertical movement of the needle board. In this embodiment, preferably, the driving mechanism 8 is composed of a gear and a rack that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com