A method for quickly changing screens and effectively protecting screens, and a vibrating screen

A technology of vibrating sieves and screens, which is applied to chemical instruments and methods, sieves, solid separation, etc. It can solve problems such as screens falling, affecting material sieving and falling, and screen wear, so as to simplify the replacement process and save replacement costs. The effect of network time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

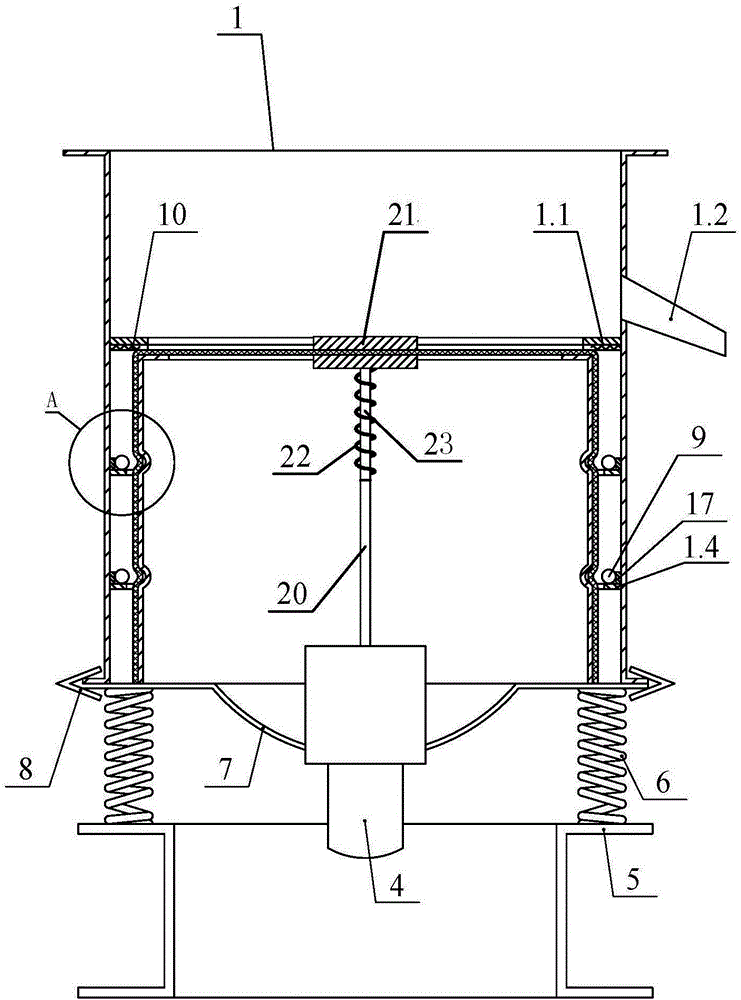

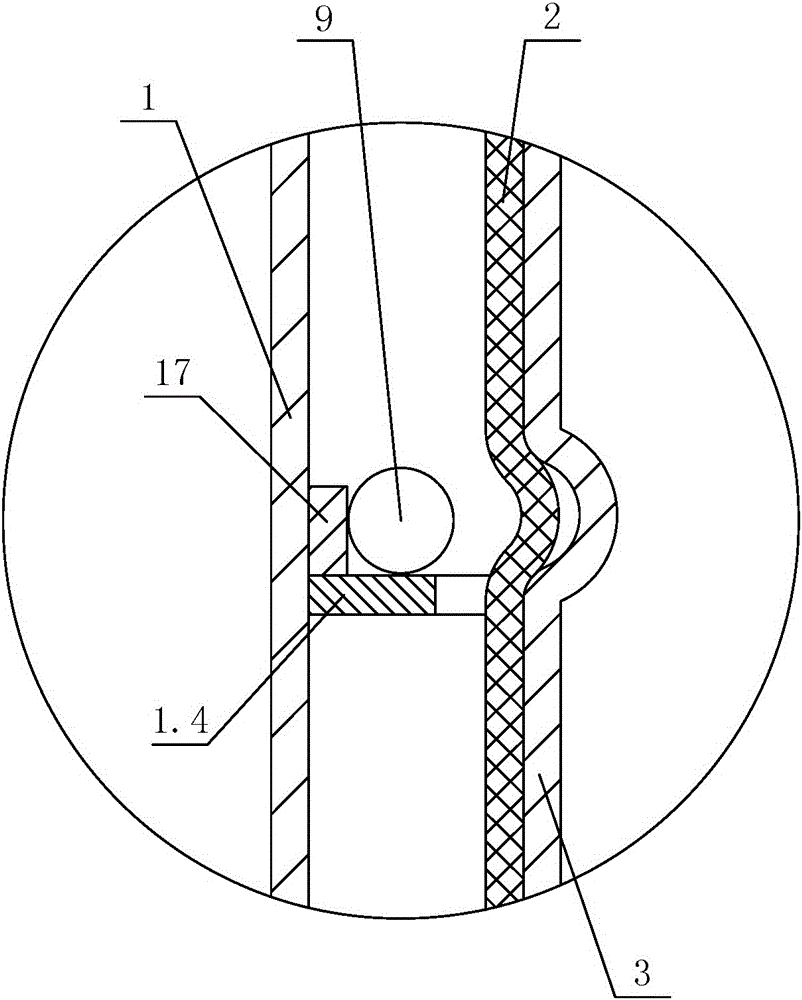

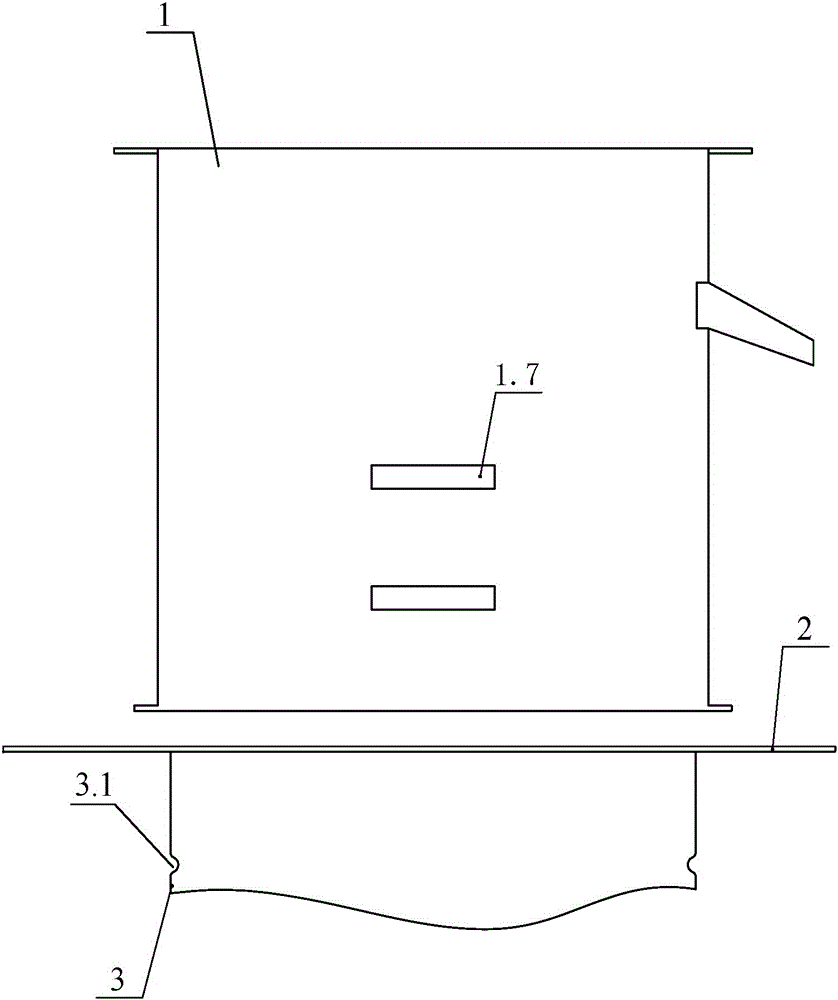

[0044] Such as figure 1 , 3 , 8, and 9, the vibrating screen of the present invention is mainly composed of a screen frame 1, a screen cloth 2, a grid frame 3, a vibrating motor 4, a base 5, a vibrating spring 6 and a vibrating body 7. The screen frame 1 is also provided with a slag outlet 1.2. One end of the baffle plate 19 is fixed on the inner wall of the screen frame 1 on both sides of the slag discharge port 1.2 and is located above the screen 2, and the other end faces the slag discharge port 1.2. The bottom edge of the baffle plate 19 is in contact with or close to the upper surface of the screen cloth 2 . In order to better improve the screening effect, the length of the baffle plate 19 on the mesh surface of the screen 2 is set as follows: at least 1 / 10 of the radius of the screen 2, at most 1 / 3, and at most about 1 / 4 good. The number of baffles 19 can be one or more than two. The grid frame 3 is located in the cavity surrounded by the screen frame 1, and an annu...

Embodiment 2

[0061] Compared with Embodiment 1, in this embodiment, the ends of the stretching hoops 9 are still intersected after passing through the screen frame 1 . The difference from Embodiment 1 is that in this embodiment, the stretching net hoop 9 is tightened by straight pulling. Such as Figure 6 As shown, the locking buckle 13 is fixed at the end of the stretching hoop 9, and the hook 12 is fixed on the outer wall of the screen frame 1. Pull the locking buckle 13 by hand to pull one end of the stretching net hoop 9 forward, hang it on the hook 12 after tightening, and then pull the locking piece of the locking buckle 13 to close the stretching net hoop 9 Tight fix.

[0062] This embodiment does not need tools to tighten, only needs to be pulled by hand, the advantage is that it is faster.

[0063] In Embodiments 1 and 2 above, the ends of the stretching hoops 9 pass through the screen frame 1 and then intersect, so that the screen 2 is tightened in the external space of the sc...

Embodiment 3

[0065] Different from Embodiments 1 and 2, in this embodiment, the stretching hoops 9 do not need to pass through the screen frame 1 . Such as Figure 7 As shown, the stretching hoops 9 of the same layer are two semicircles, and the two stretching hoops 9 are correspondingly arranged to form a ring, and the end of one stretching hoop 9 is connected to the end of the other stretching hoop 9. The corresponding ends are relatively close to each other. Fix the coupling piece 16 at the end of the stretching net hoop bar 9, penetrate the fastening bolt 14 in the two relative coupling pieces 16, and set the nut 15 on the fastening bolt 14.

[0066] An operating hole 1.3 is set at the position of the screen frame 1 corresponding to the end of the stretching hoop 9, and a wrench is inserted into the operating hole 1.3 to turn the nut 15, and the two stretching hoops 9 are relatively tightened, and the screen 2 Straighten it up and say no more. The meaning of opening the operation hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com