Novel clamp

A fixture, a new type of technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problems of clamping parts, complex structure of clamping methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

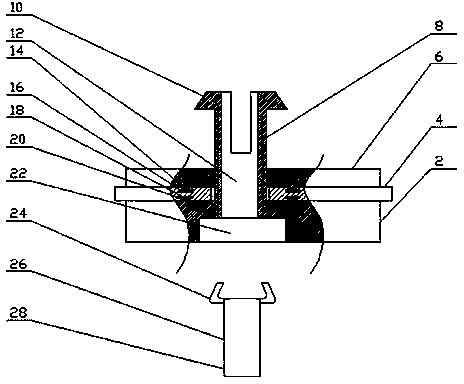

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] The present invention includes a base and a lifting and lowering clamping assembly arranged on the base. The expansion rod 26 in the first through hole 12 of the clamping sleeve 8, the clamping sleeve 8 is fork-shaped at least partly but including its upper end, and the upper end is provided with protrusions protruding to both sides 10. The lower surface of the raised portion 10 is a plane perpendicular to the clamping sleeve 8, and the expansion rod 26 includes a rod-shaped expansion rod body 28 that is loosely fitted with the first through hole 12 and extends to both sides. The elastic claw 24 that protrudes above the side.

[0013] Pass the hole of the workpiece through the clamping sleeve 8, and prop up the clamping sleeve 8 through the expansion rod 26. At this time, the protrusion 10 of the expansion rod 26 and the upper surface of the base pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com