Fully-automatic feeding point front and back milling equipment

A fully automated, feeding point technology, applied in the field of milling equipment, can solve the problems of low labor efficiency and waste labor costs, and achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments:

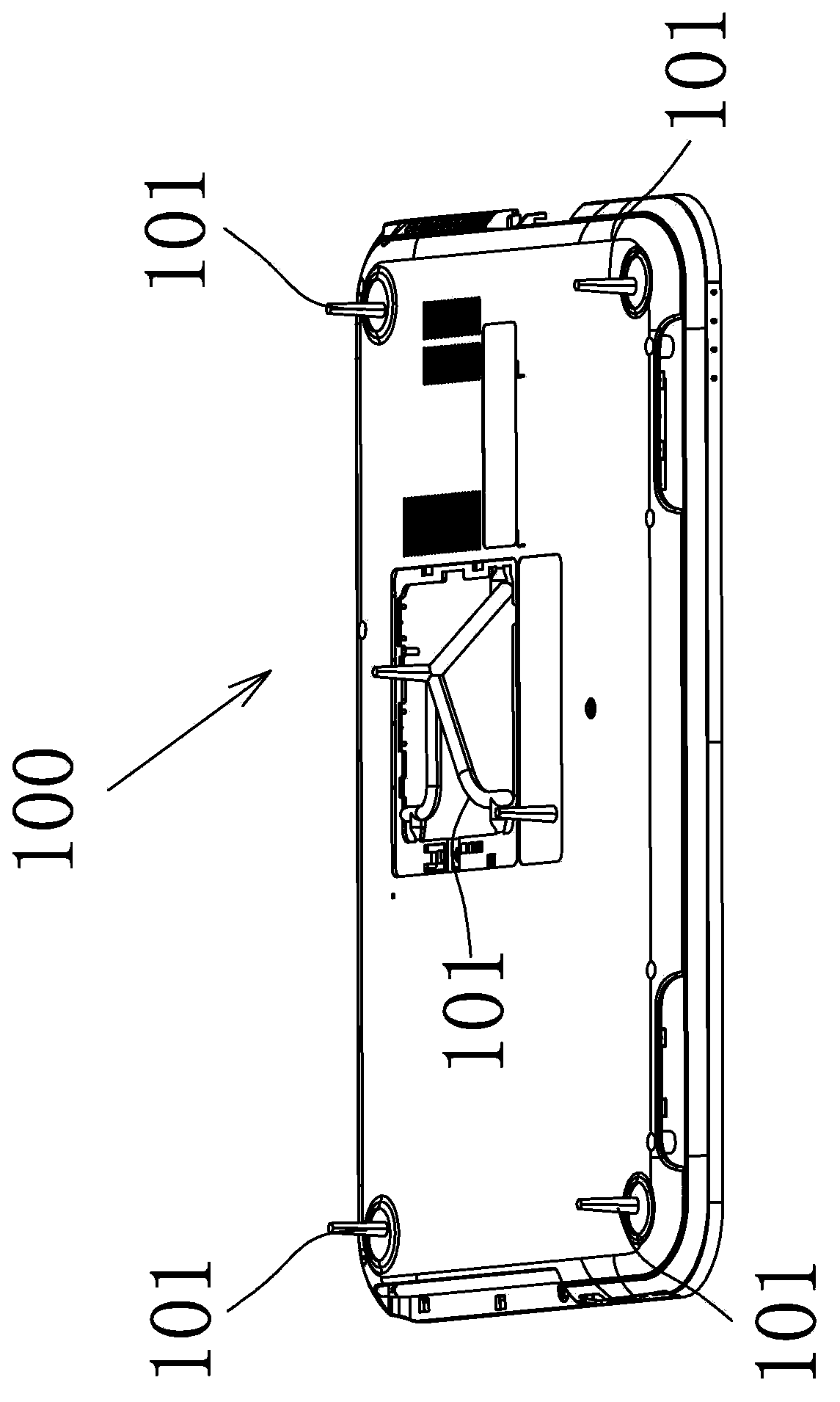

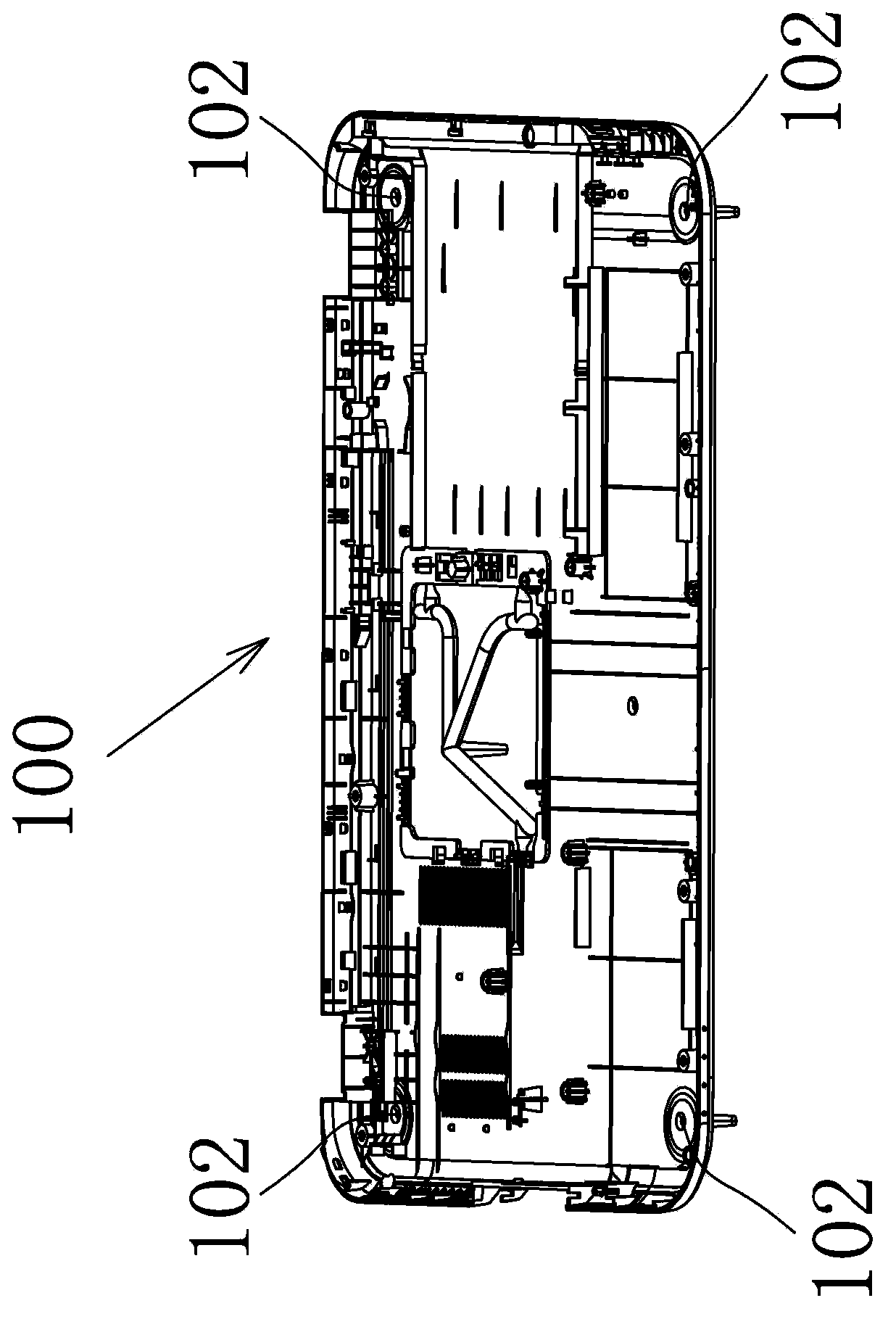

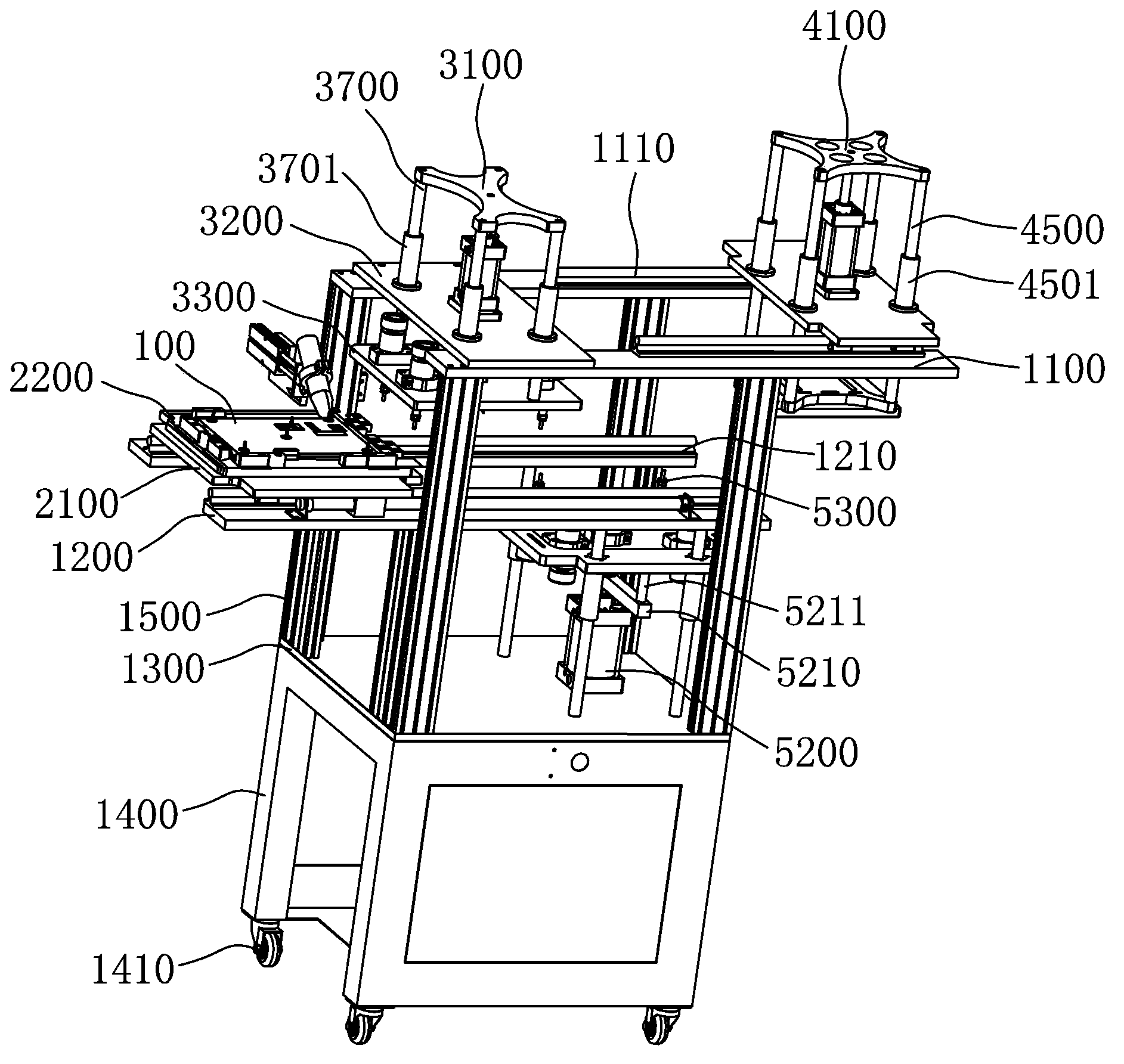

[0027] Please refer to figure 1 and figure 2 , the preferred embodiment of the fully automatic forward and reverse milling feed point equipment of the present invention is used for milling the glue feed point and cold feed well of a product 100. In this embodiment, the product 100 includes several front glue feed points 101 and Some reverse cold slug wells 102. Please refer to image 3 and Figure 4 , the fully automated front and back milling feed point equipment includes:

[0028] A transmission mechanism, which includes two upper cross bars 1100 parallel to each other, two lower cross bars 1200 parallel to each other, and a lower fixing plate 1300; And the lower pivot is connected on the four support rods 1500;

[0029] A feeding mechanism, which includes a sliding platform 2100, a positioning fixture 2200, an inductor (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com