Method for installing buckle locking section of caterpillar band

An installation method and hasp lock technology, which are applied to tracked vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of high work intensity and low efficiency, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

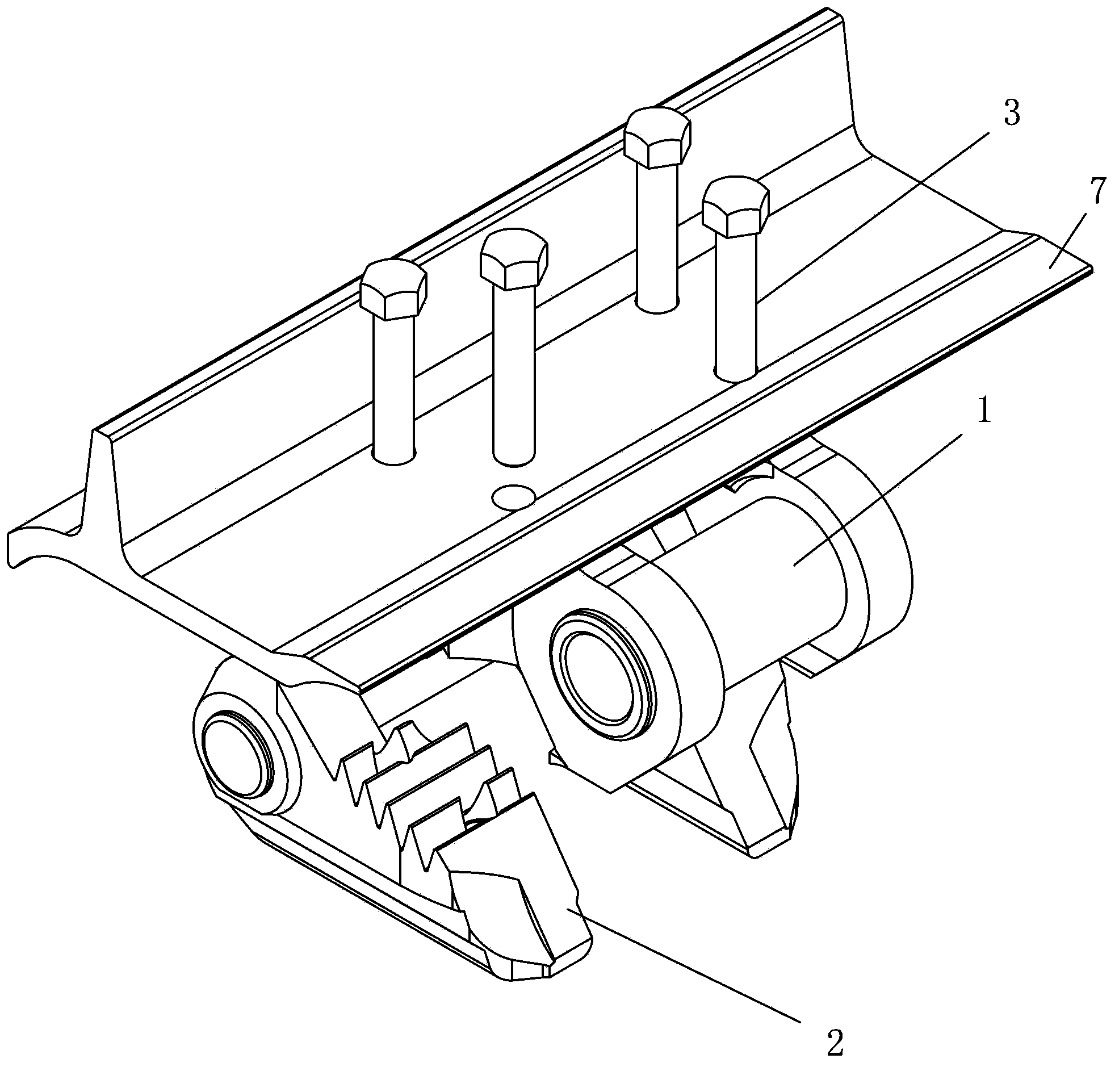

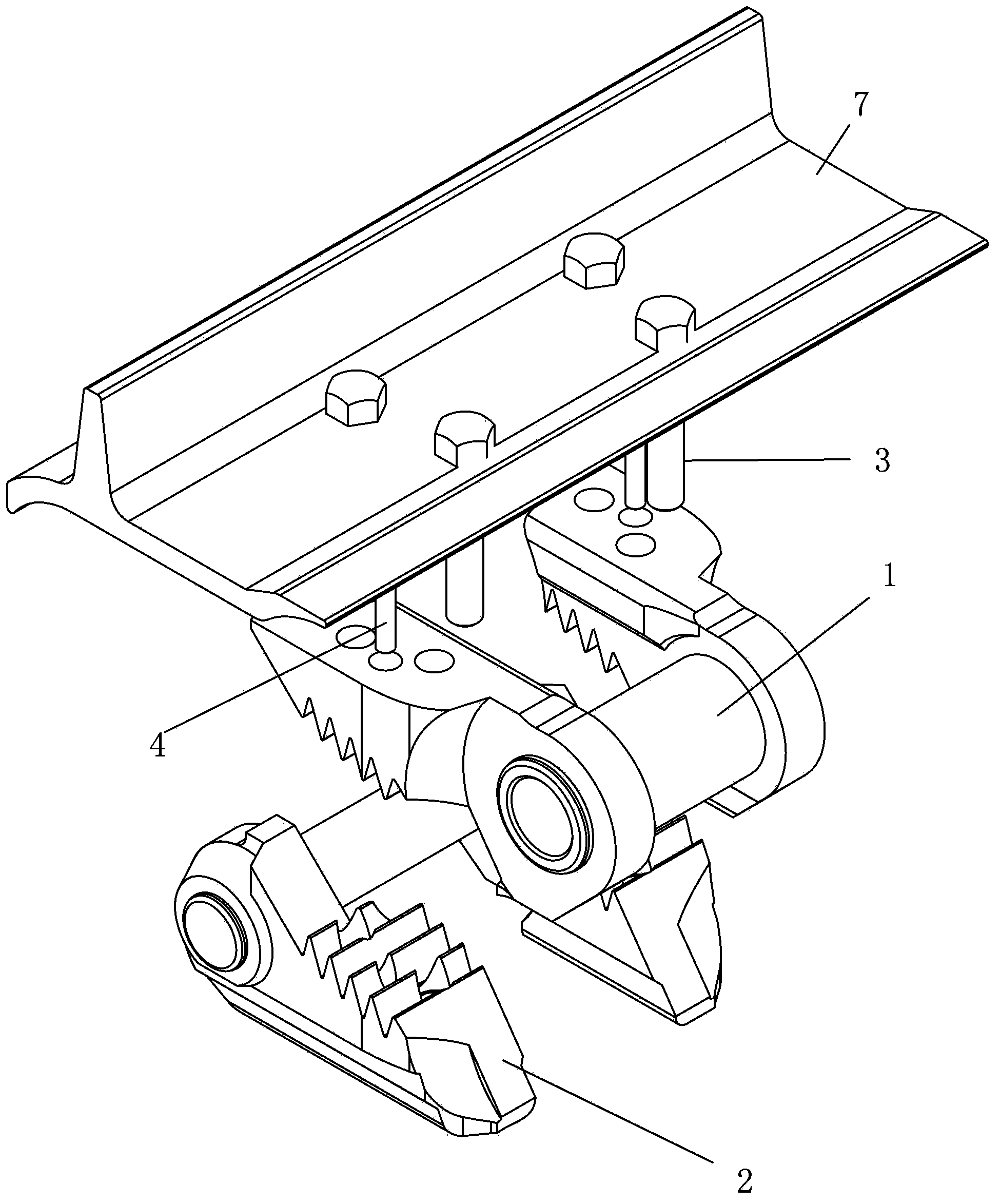

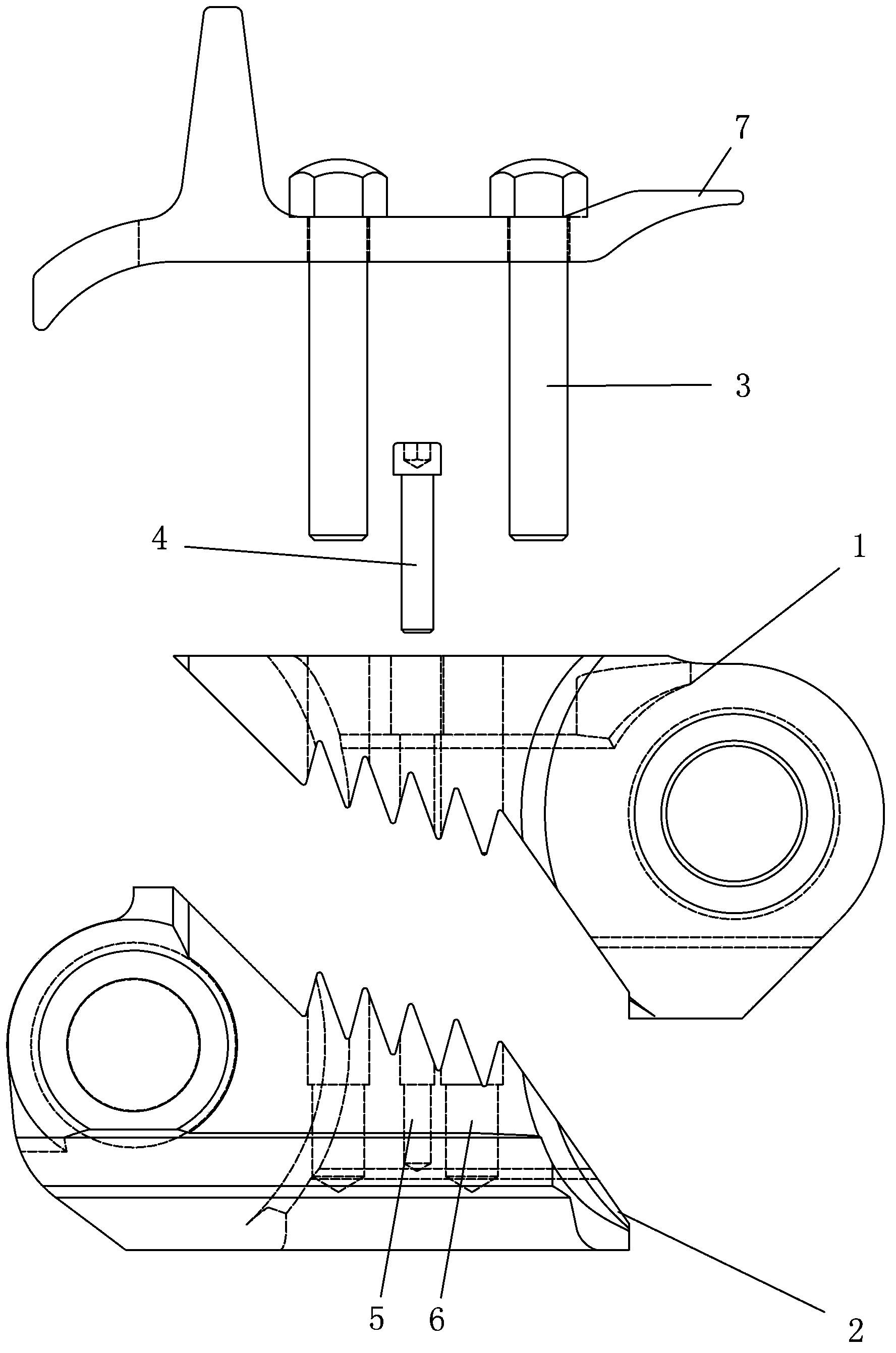

[0016] The installation method of the locking joint of the track buckle of the present invention is as follows: figure 2 and 3 As shown, the upper locking segment 1 and the lower locking segment 2 are first fixed together through the middle locking bolt 4 pierced from top to bottom; The locking segment 1 and the lower locking segment 2 are fixed together. In the figure, number 5 is a threaded hole in the lower locking segment 2 for fixing the locking bolt 4 ; and number 6 is a threaded hole in the lower locking segment 2 for fixing the fixing bolt 3 .

[0017] In a preferred manner, the locking bolt 4 is an M12 inner hexagonal bolt located between the two screw holes 6 of the hasp locking joint. The specific installation steps are.

[0018] 1. Put the two halves of the buckle locking section together first, and screw the two halves of the locking section together with an M12 bolt. At this time, the two halves of the locking section are combined into a whole, which brings c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com