Cocoon cooking device and process capable of enabling cocoon cavity not to contain water

A cocoon cooking and crafting technology, which is applied in silk fiber production, textile and papermaking, mechanical treatment, etc., can solve the problems of insufficient drainage of the cocoon cavity and uneven cooking, so as to avoid the uneven conduction of steam heat and ensure uniform and moderate cooking , improve the effect of relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

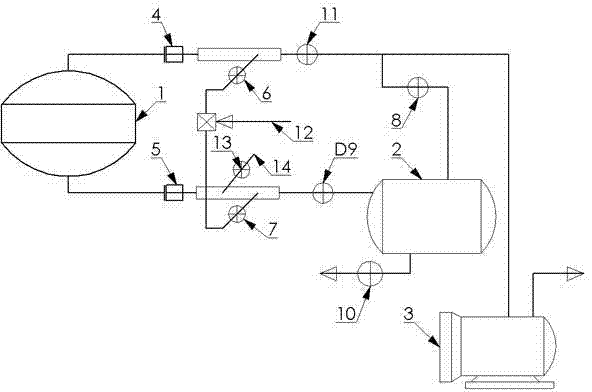

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0030] like figure 1 , the present invention provides a cocoon cooking device without water in the cocoon chamber, comprising: main tank 1, multiple system pipelines, multiple solenoid valves 6, 7, 8, 9, 10, 11, 13, auxiliary tank 2, vacuum pump 3 and the steam inlet 12 and liquid water inlet 14 on the system pipeline, the upper part of the main tank 1 has an upper intake and exhaust pipe 4, and the lower part of the main tank 1 has a lower intake and exhaust pipe 5; the upper intake and exhaust pipe 4 passes through the system Pipeline A is connected to vacuum pump 3, solenoid valve F11 is installed on system pipeline A between upper intake and exhaust pipe 4 and vacuum pump 3, and solenoid valve is installed on system pipeline B connecting upper intake and exhaust pipe 4 and steam inlet 12 A6, a solenoid valve B7 is installed on the system pipeline C connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com