Cloth pressing sheet

A technology for pressing cloth and cloth, which is applied to textiles, papermaking, knitting, etc., can solve the problems of difficult installation of the cloth pressing and difficulty in entering the cloth into the cloth pressing port, etc., and achieves the effect of simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Describe an embodiment below in conjunction with accompanying drawing, the present invention is further described.

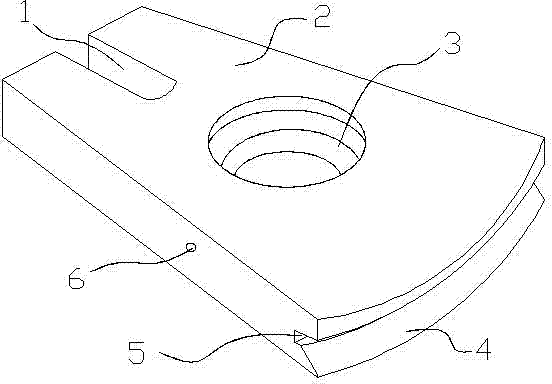

[0012] exist figure 1 Among them, a cloth pressing sheet 2 includes a cloth pressing sheet 2, one end of the cloth pressing sheet 2 has a positioning tip movement groove 1, and the other end has a slender cloth pressing groove 5; the middle of the cloth pressing sheet 2 has a Circular eccentric wheel shaft fixing port 3, said eccentric wheel shaft fixing port 3 is provided with latch 6; said side located at the lower edge of cloth pressing groove 5 is provided with a guide surface 4, and guiding surface 4 extends into cloth pressing groove 5.

[0013] The above implementations are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any creative improvements, equivalent replacements, etc. that are not made within the spirit and principles of the present invention should be included within the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com