Cloth feeding mechanism for sewing machine

A technology of a cloth feeding mechanism and a sewing machine, which is applied in the field of sewing machines, can solve the problems of high manufacturing cost, lower market competitiveness, and large structural differences of a comprehensive cloth feeding thick material machine, and achieve the effects of simple structure, low manufacturing cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

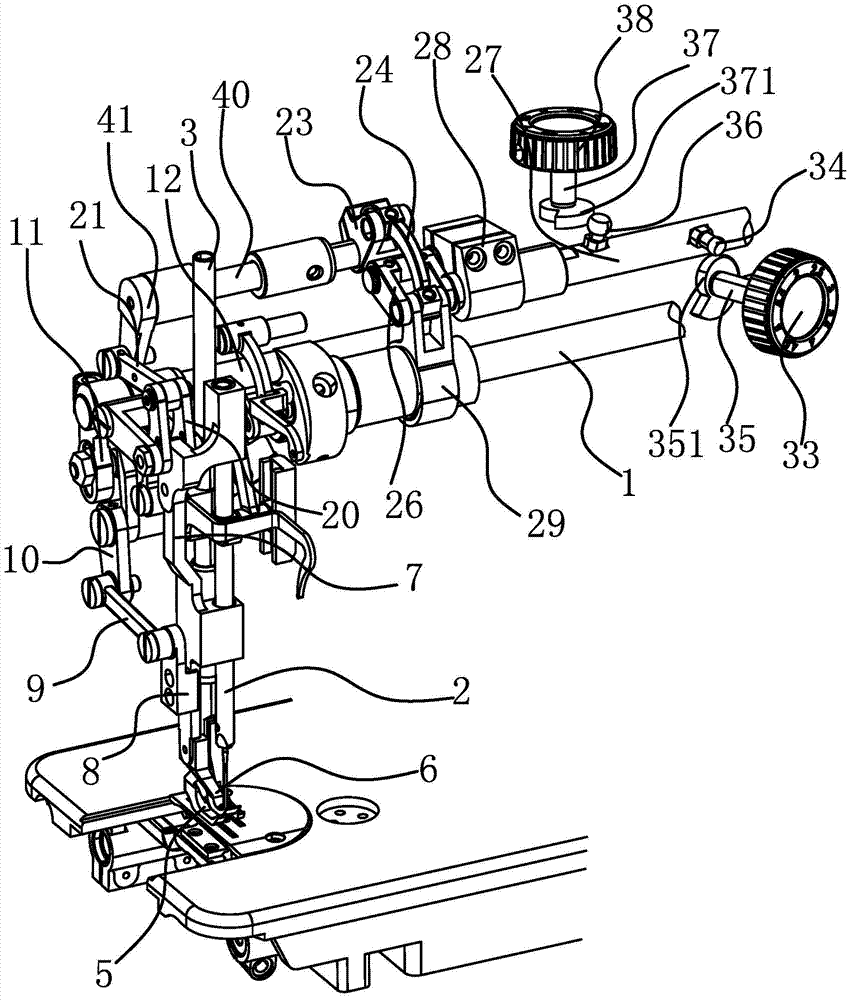

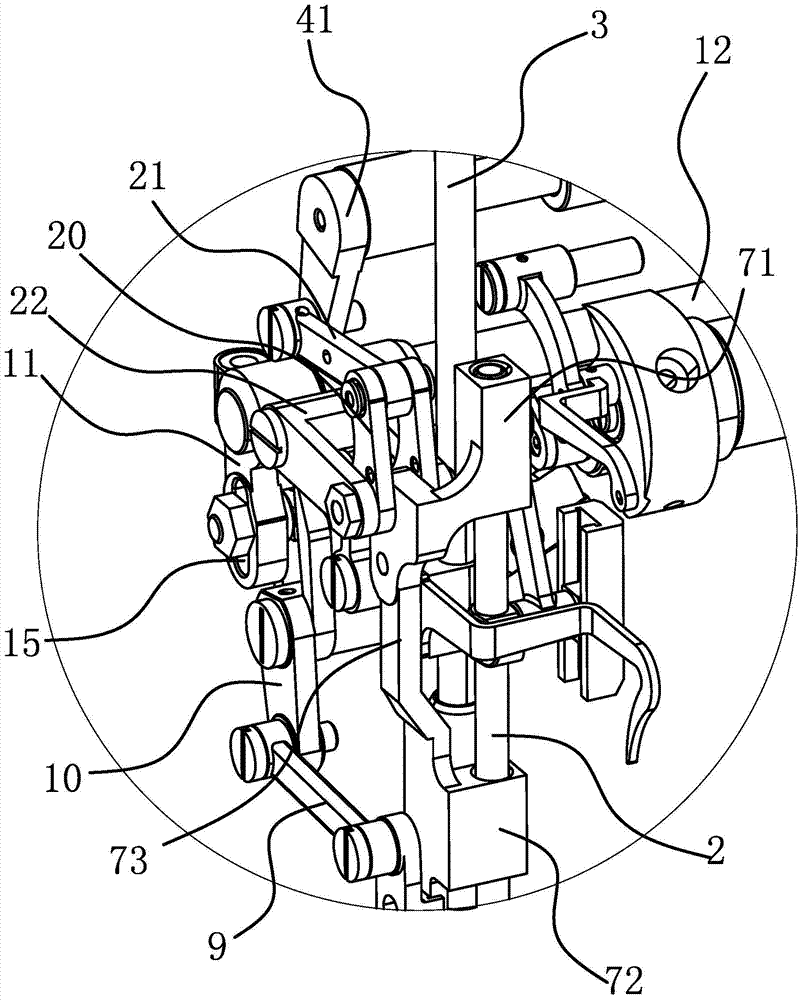

[0028] The cloth feed mechanism of this sewing machine comprises parts such as main shaft 1, needle bar 2, pressure bar 3, inner presser foot 6, presser foot connecting rod 7 and the feed dog driving shaft 4 for driving the movement of cloth feed dog.

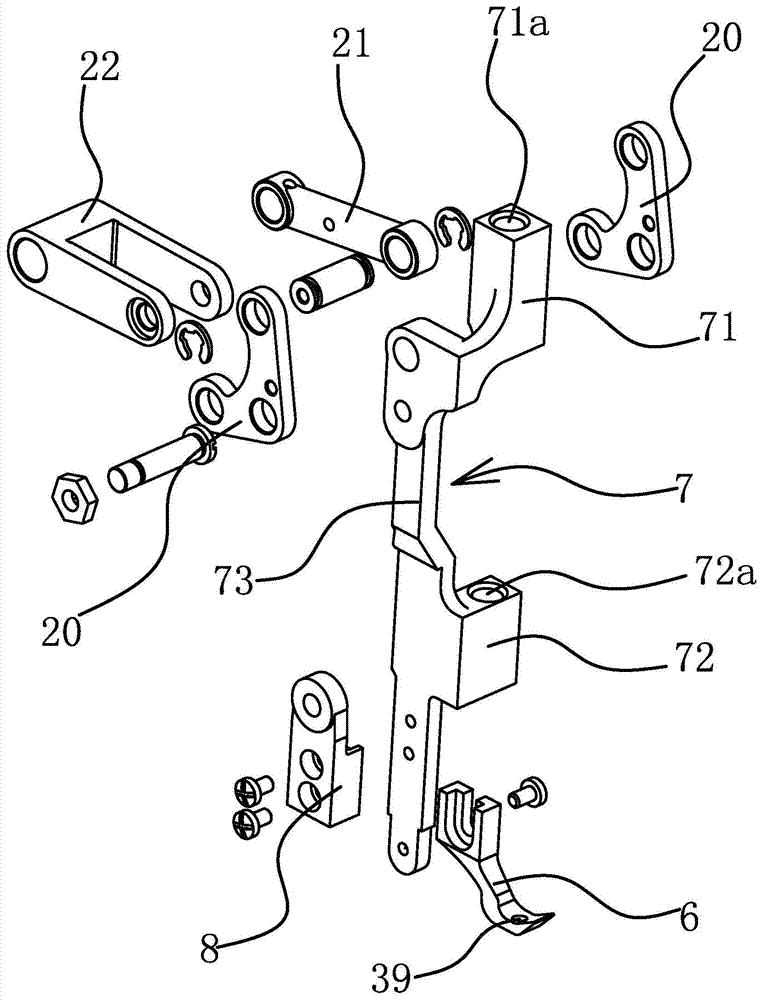

[0029] Such as figure 1As shown, the lower end of the pressing bar 3 is fixedly connected with the outer presser foot 5, and the inner presser foot 6 is fixedly connected with the lower end of the presser foot connecting rod 7, and the inner presser foot 6 is provided with a needle through hole 39 for the machine needle to pass through. The presser foot connecting rod 7 comprises an upper mounting portion 71, a lower mounting portion 72 and a strip-shaped connecting portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com