Coal bed gas flow condition rapid recognition method based on starting pressure gradient

A technology for starting pressure gradient and coal seam gas, which is applied in earth-moving drilling, wellbore/well components, etc., can solve problems such as evaluation of the difficulty of extraction and deviation of extraction process selection, and achieve the effect of improving the accuracy of production capacity prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

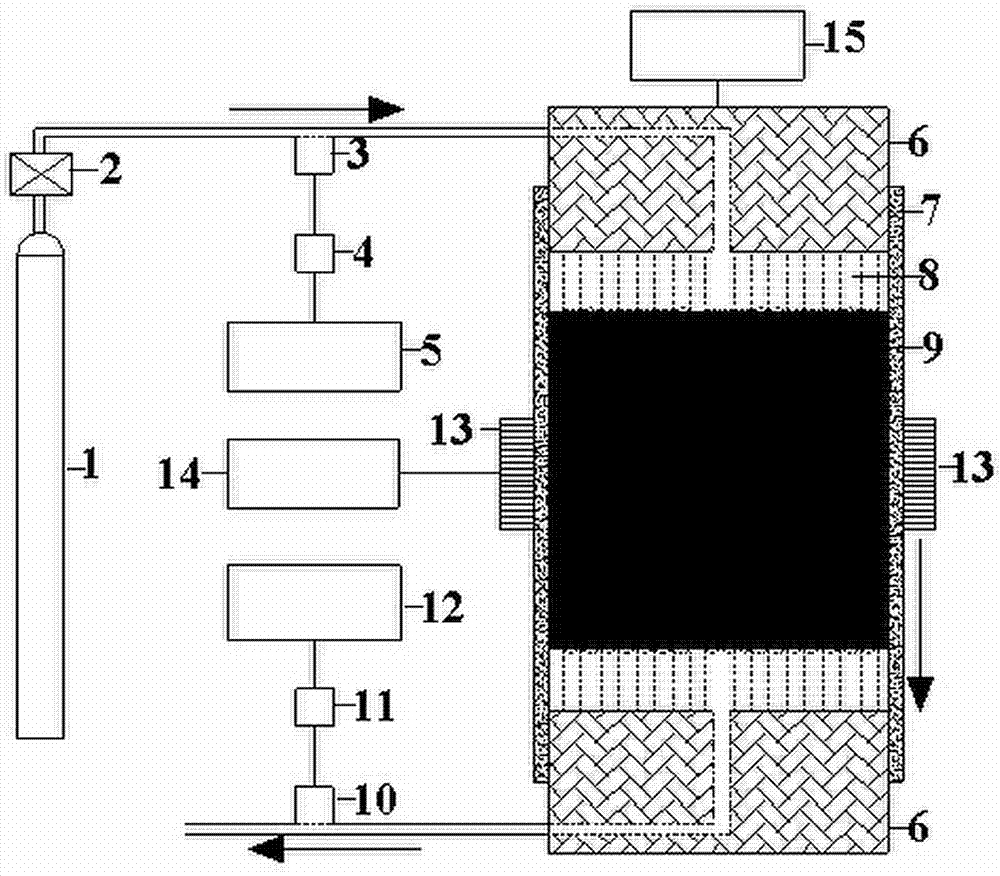

[0033] Example: see figure 1 —7.

[0034] A method for quickly identifying the flow state of coal seam gas based on the threshold pressure gradient, characterized in that it includes the following steps:

[0035] The first step is to collect representative samples of Type I non-destructive coal, Type II damaged coal, Type III strongly damaged coal, Type IV pulverized coal, and Type V pulverized coal in underground coal mines;

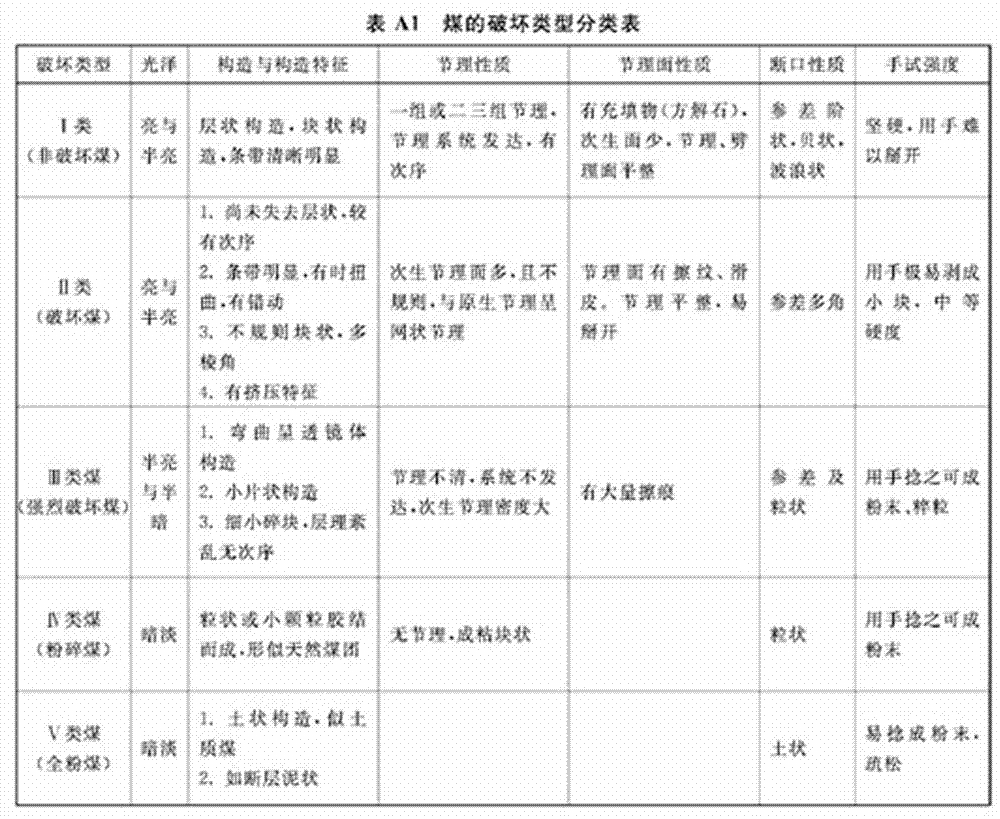

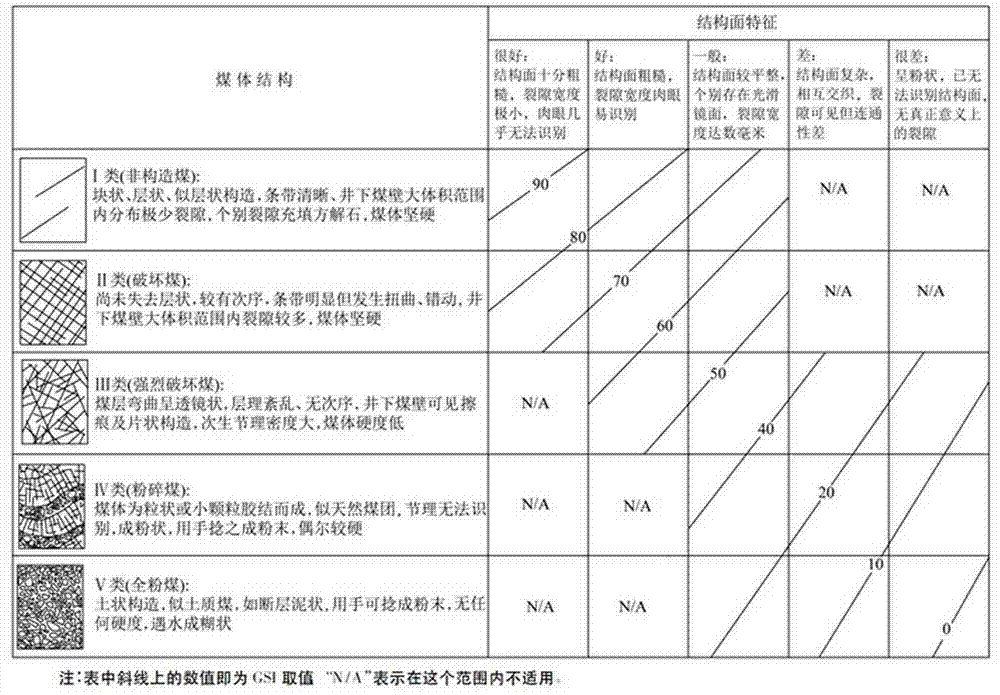

[0036]The criteria for judging the five types of coal samples have been clearly stipulated in the industry standard "Coal and Gas Outburst Mine Appraisal Specification" (AQ 1024-2006), and many other documents have also been made public. figure 1 Selected from the "Coal and Gas Outburst Mine Appraisal Code" (AQ 1024-2006), it is a classification table of coal damage types.

[0037] In the second step, each coal sample is made into a standard coal core with the same specifications in the laboratory. In this embodiment, the standard coal core is a cyl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap