Gaseous fuel rail depressurization during inactive injector conditions

A gaseous fuel and fuel technology, applied in fuel injection devices, electrical control, charging systems, etc., can solve problems affecting fuel economy and engine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

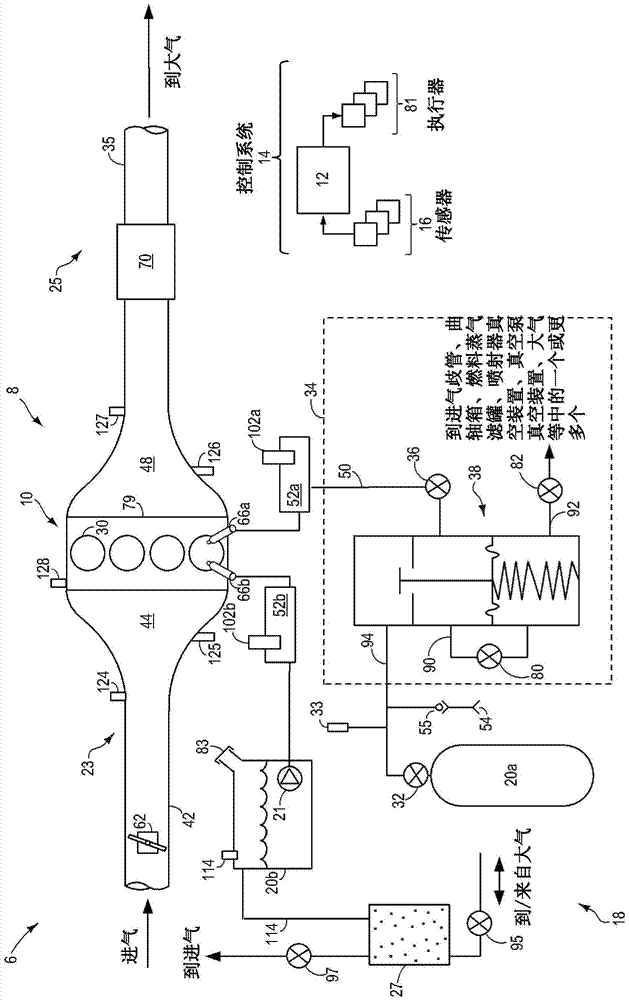

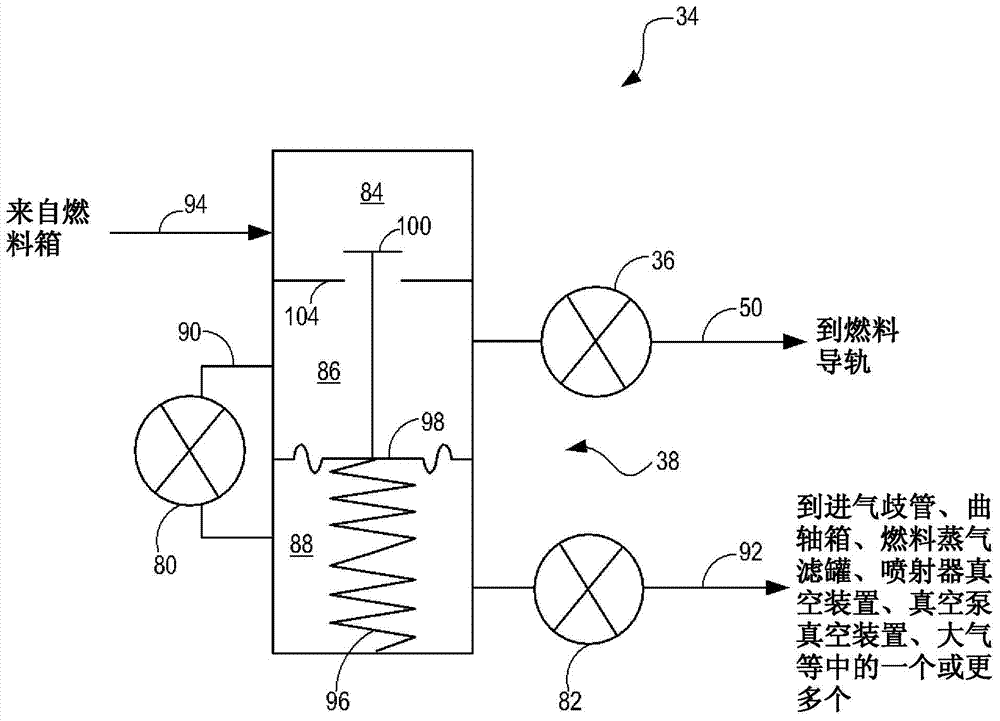

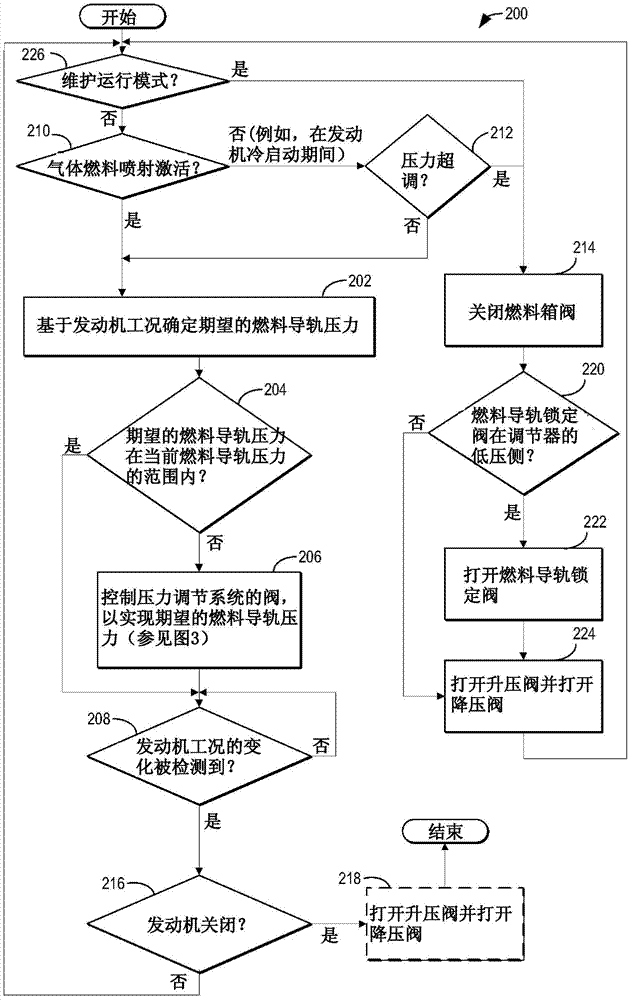

[0025] Methods and systems are provided for variable pressure regulation of gaseous fuels to reduce e.g. Figure 1A Fuel pressure overshoot in the vehicle system of the system. Vehicle systems include pressure regulation systems such as Figure 1A -B shows the system, which can be based on figure 2 and image 3 method runs. For example, a valve in a pressure regulating system can be based on figure 2 and image 3 The method operates to depressurize a reference chamber of a regulator when a fuel injector is deactivated (eg, before or during an engine cold start) and to vary the regulated pressure of the system based on engine operating conditions when the fuel injector is activated. Changing the pressure in the reference chamber changes the regulated pressure of the regulator, which in turn changes the engine fuel rail pressure, thereby providing variable injection pressure of the gaseous fuel. exist Figure 4 The relationship between various parameters of the pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com