Voltage-controlled self-overflow electric water heater

An electric water boiler and self-overflow technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of lack of commercialization and humanized design, unhealthy drinking water, ugly appearance, etc., to save stainless steel materials, low cost, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

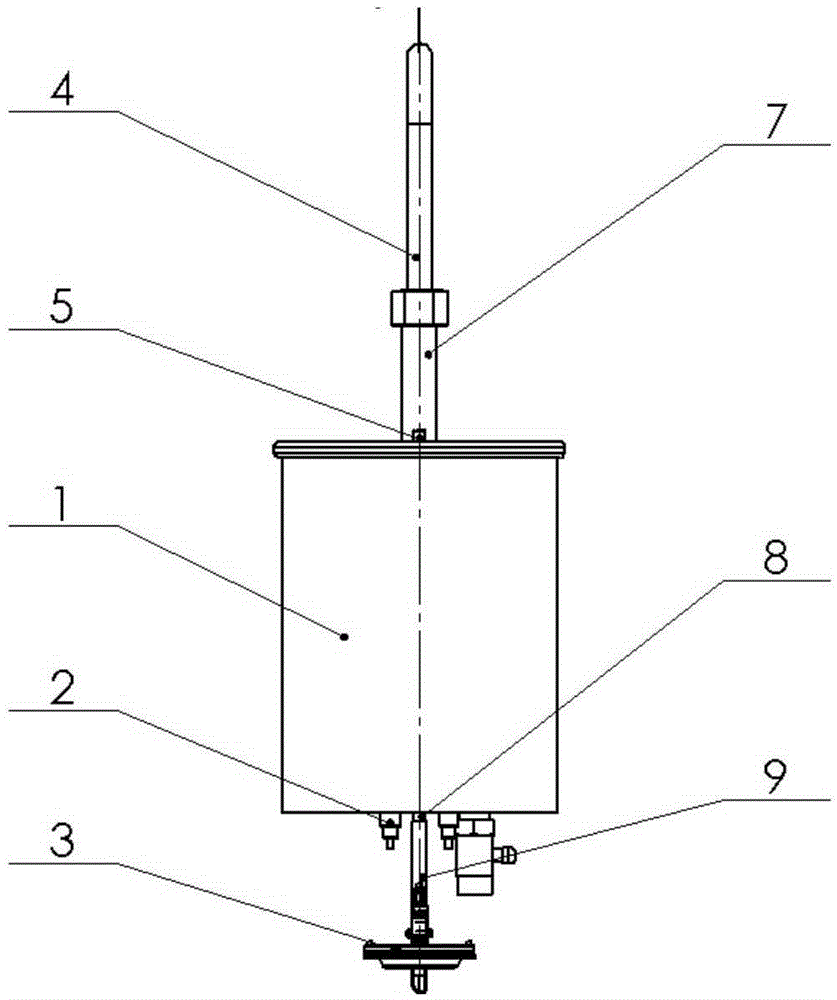

Embodiment 1

[0046] like Figure 5-8 As shown, the pressure detection controller 3 consists of a disc valve housing 31, a rubber template 32, a mounting ring 33, a mounting frame 34, an adjusting wire seat 35, a shape-retaining load-bearing cap 36, a guide rod 37, a restoring spring 38, Guide pipe 39, water inlet switch 3A, heating switch 3B, switch shaft 3C, adjusting screw 3D, assembly screw 3E, water pipe seat 3F; Cavity 1 is communicated, and the other side of formwork 32 is communicated with atmosphere; The central part of formwork 32 upper surface is provided with conformal load-bearing cap 36, can suppress the deformation of template central part, and undertake formwork pressure; The guide rod 37 is covered with a return spring 38; the pressure detection controller 3 also includes a water inlet switch 3A for controlling the water inlet pipe 4 and a heating switch 3B for controlling the heating element 2 ; Installed on the mounting frame 34 by the switch shaft 3C, the switch contact...

Embodiment 2

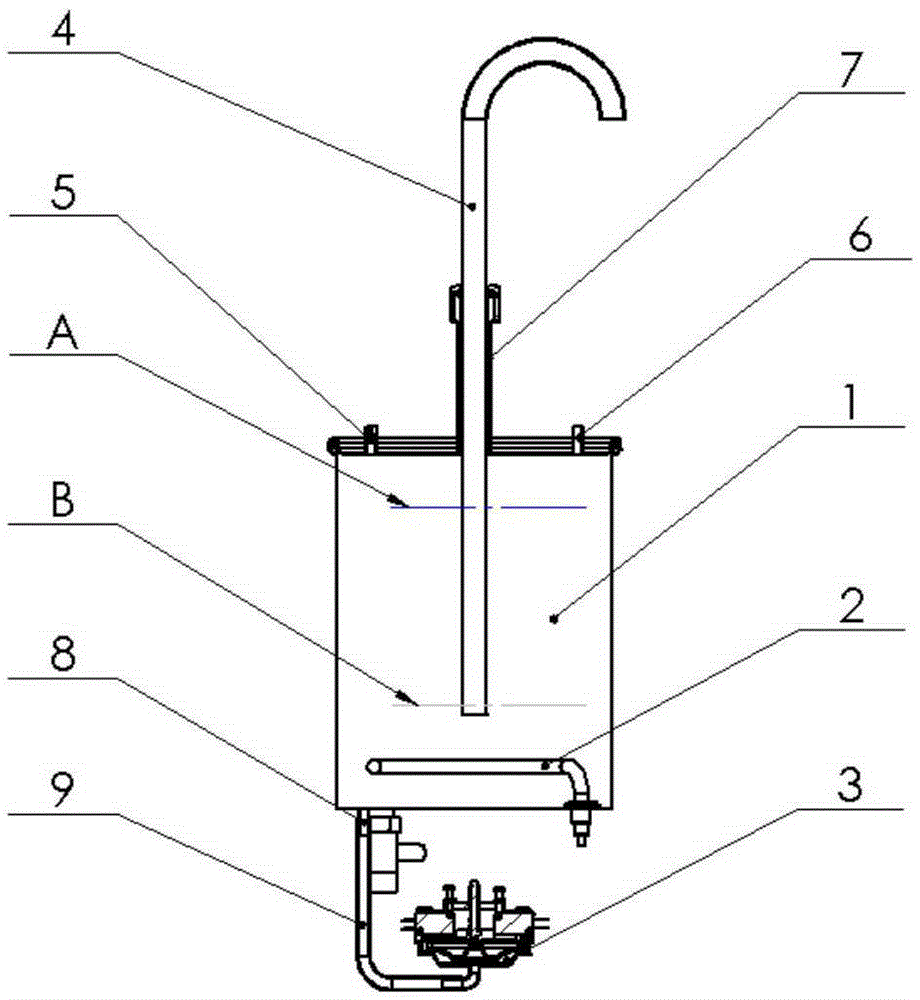

[0048] The drain valve 8 is installed at the bottom of the heating chamber 1; the heating element 2 is installed at the bottom of the heating chamber 1; the water inlet pipe seat 5 can be installed at any position of the heating chamber 1; There is enough space to place the water intake container; the flow-limiting air pipe 6 is installed on the top of the heating chamber. The upper water level A can be set as required.

[0049] like Figure 10 Shown is the outline drawing of a water boiler suitable for municipal water supply with a solenoid valve; a water purifier can be installed in the box below the water tray.

Embodiment 3

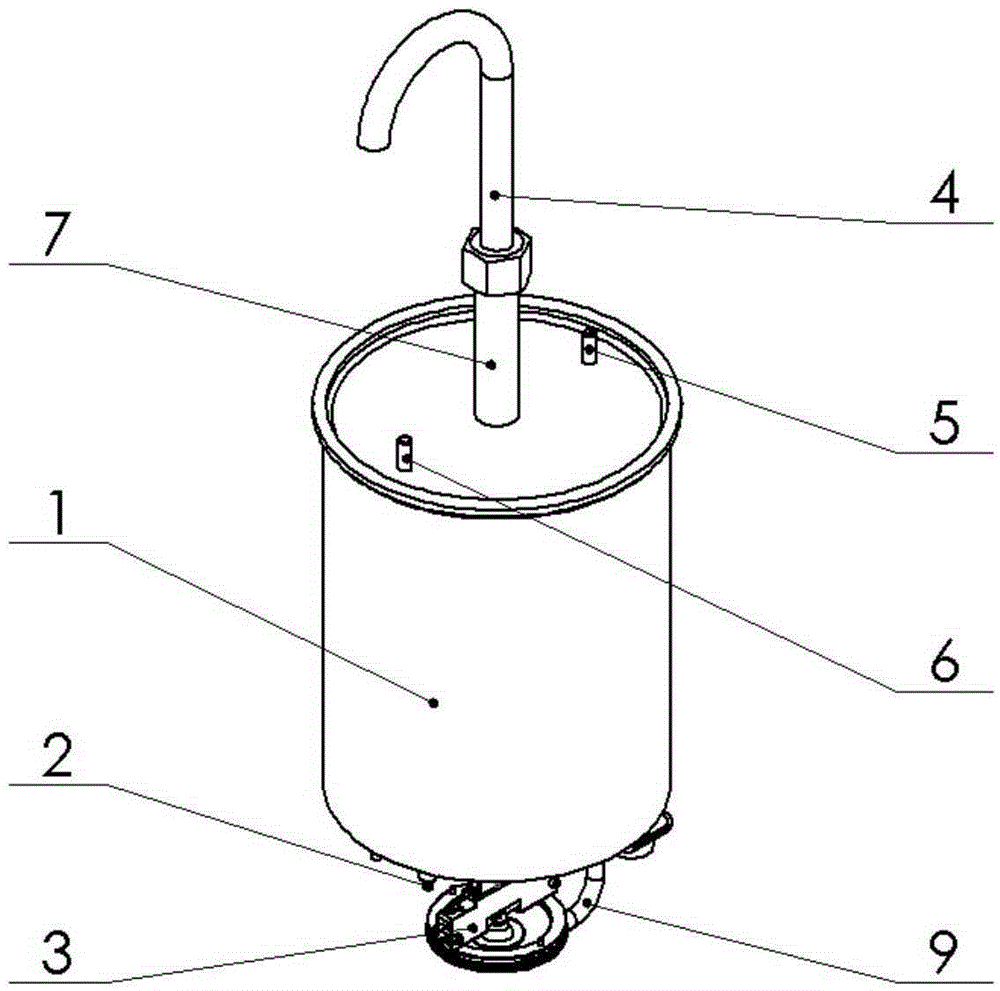

[0051] The water inlet control part of above-mentioned water inlet pipe 5 can adopt electromagnetic valve, miniature water pump etc. When the water inlet pipe is connected to a large bucket of water, such as Figure 11 Shown is the situation that is adapted to the water supply of vat water, is the water dispenser that combines water intake with miniature water pump and one-way valve;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com