Floor strength grade detection device and floor strength grade detection method

A strength grade and detection device technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable bending force, etc., can solve problems such as uneconomical, waste of man-hours, cumbersome operation process, etc., to achieve Cost savings, less time-consuming operation, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

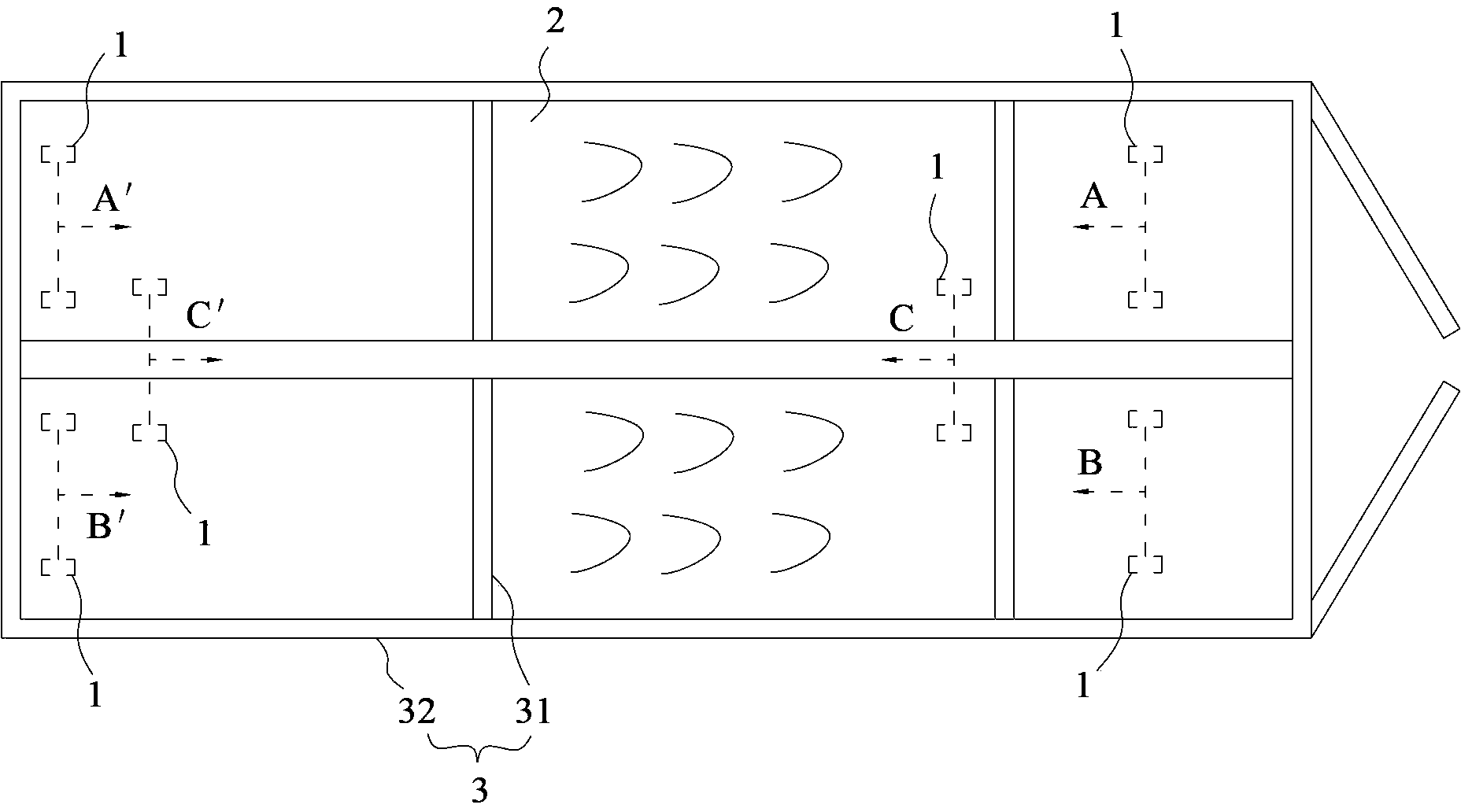

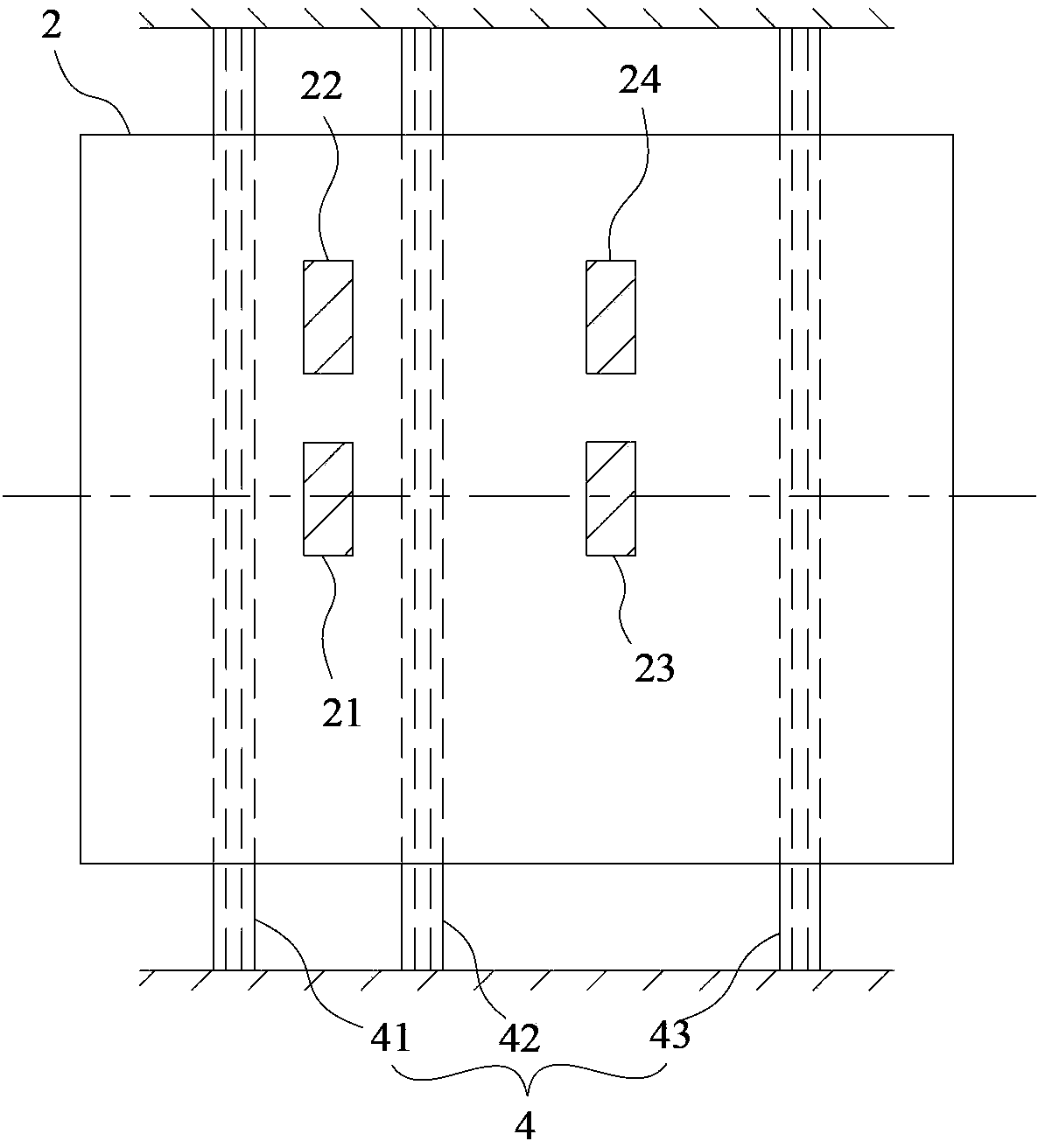

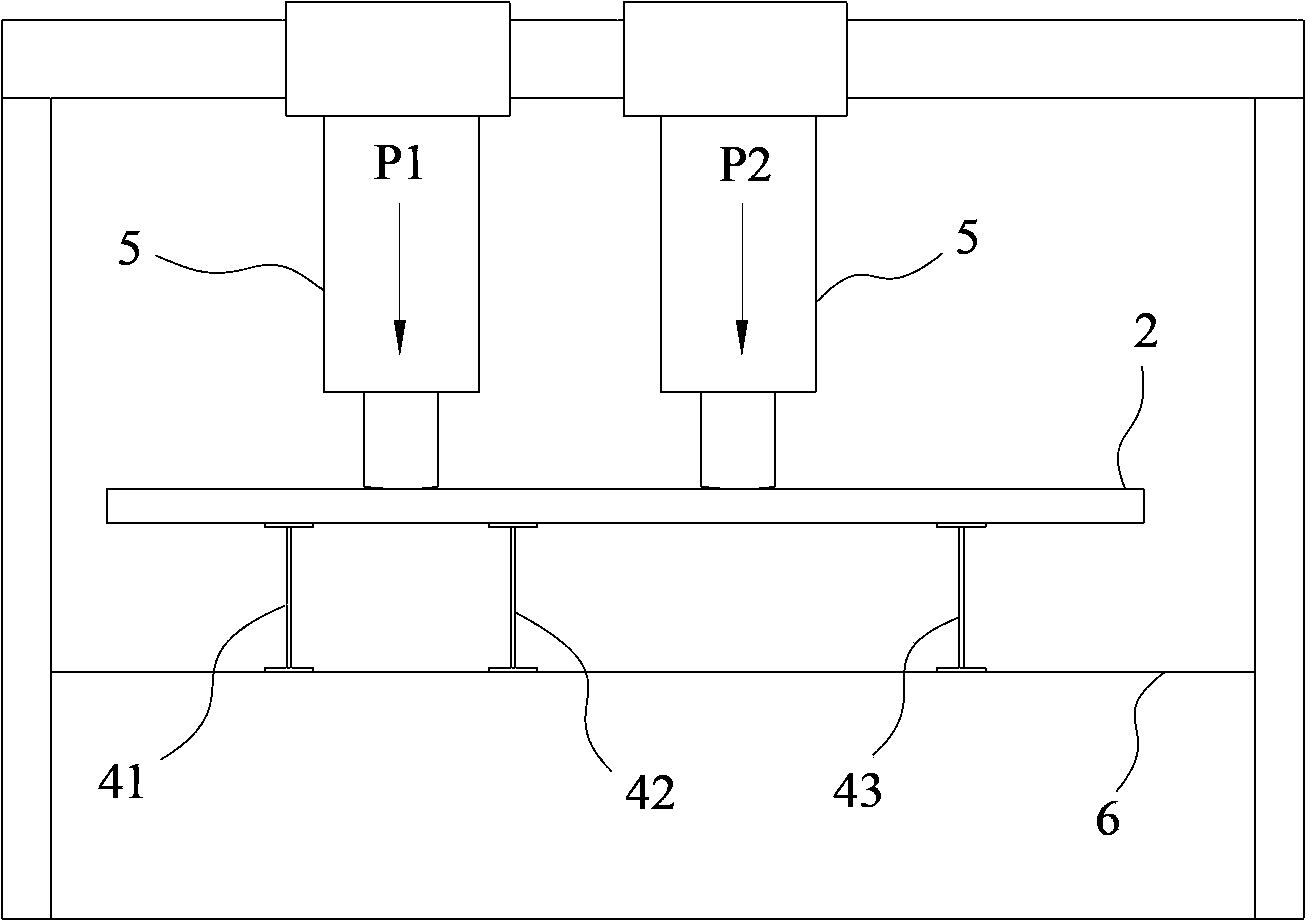

[0023] see figure 2 and image 3 As shown, the floor strength level detection device of the present invention includes three supporting beams 4 and at least one loading member 5 , and may also include a testing platform 6 .

[0024] The three support beams 4 are arranged in parallel and at intervals, and the tops of the support beams 4 are of the same height to form a supporting plane for supporting the floor 2 . Each supporting beam 4 can be a channel beam or an I-shaped beam. The three support beams 4 are successively arranged horizontally as a first support beam 41, a second support beam 42 and a third support beam 43, between the first support beam 41 and the second support beam 42 The distance between the second support beam 42 and the third support beam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap