An arc-extinguishing current-limiting fuse using epoxy resin insulating porcelain bottle

A technology of insulating porcelain bottle and epoxy resin, applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of large electric arc, circuit system damage equipment, etc., and achieve the effect of easy maintenance, easy maintenance and good arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

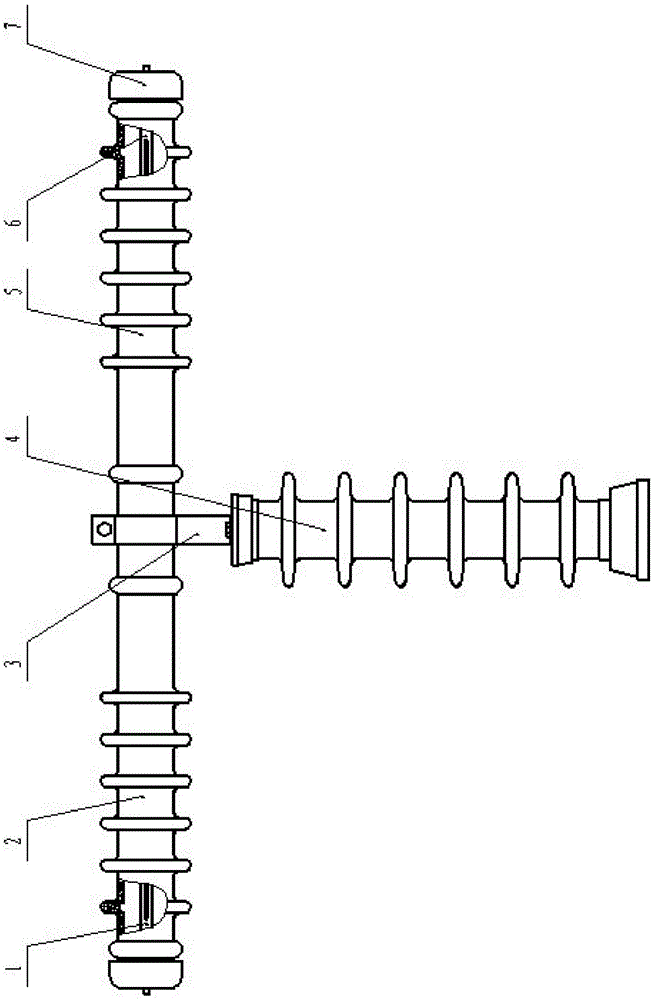

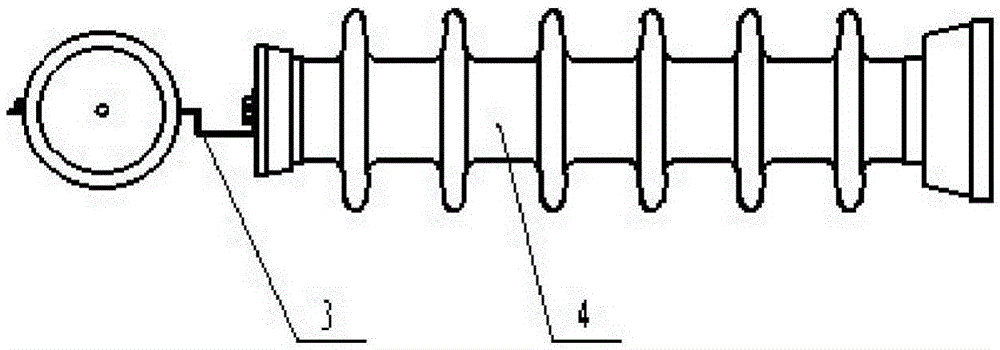

[0021] Such as figure 1 , figure 2 As shown, the present invention comprises a left insulating porcelain bottle 2 and a right insulating porcelain bottle 5 made of epoxy resin material, the left insulating porcelain bottle 2 is provided with a left melt pipe 1, the right insulating porcelain bottle 5 is provided with a right melt pipe 6, and the left insulating porcelain bottle 5 is provided with a right melting pipe 6. The melt pipe 1 and the right melt pipe 6 are provided with a fuse, and one end of the left insulating porcelain bottle 2 and the right insulating porcelain bottle 5 is connected by a fastening flange 3, and one end of the fastening flange 3 is connected with the rod-shaped pillar 4, and the left One end of the melt pipe 1 and the right melt pipe 6 are connected to each other, and the other end is respectively connected with the left insulating porcelain bottle 2 and the right insulating porcelain bottle 5 through the terminal cap 7. The left melt pipe 1 and t...

Embodiment 2

[0024] The difference from Embodiment 1 is that the slits are rectangular, the direction is parallel to the axial directions of the left melt pipe 1 and the right melt pipe 6, and the number of slits is one.

[0025] In this embodiment, since the narrow slit is rectangular and its direction is parallel to the axial directions of the left melt pipe 1 and the right melt pipe 6, the arc of the fuse blown is more likely to occur in the narrow slit, and the arc extinguishing effect is better.

Embodiment 3

[0027] The difference from Embodiment 2 is that the two ends of the fastening flange 3 are respectively fixed by screws.

[0028] In this embodiment, the fastening flange 3 is disassembled by screws, so that the left insulating porcelain bottle 2 and the right insulating porcelain bottle 5 can be quickly disassembled, and it is more convenient to replace the fuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com