Preparation method and application of all-solid-state electrolyte

An electrolyte and all-solid-state technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems affecting the battery interface structure and low chemical stability, and achieve stable interface characteristics and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

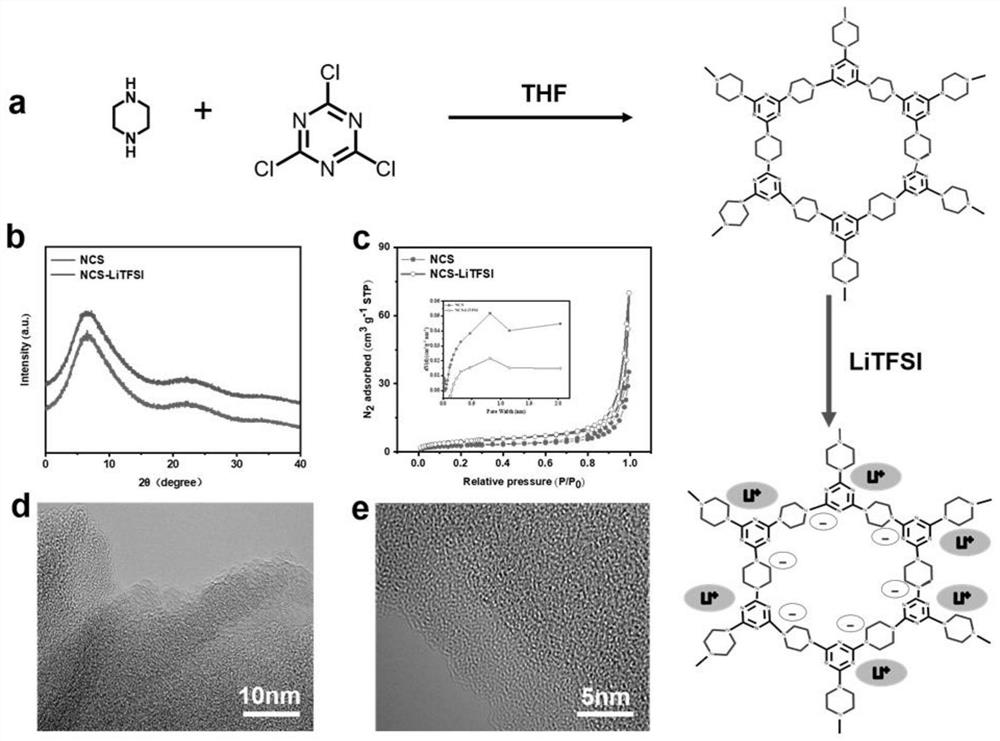

[0029] Preparation of NCS (nitrogen-doped conjugated framework material): It was prepared by one-step polymerization in the reaction system of Thiotriazinone and Piperazine. First, cyanuric chloride (73.8.mg, 0.4mmol, CAS : 108-77-0) was dissolved in 10 mL of THF (tetrahydrofuran), cooled to 0 °C, then piperazine (51.7 mg, 0.6 mmol, CAS No.: 110-85-0) was added, and the polymerization was carried out in an ice bath for 4 hours , the white precipitate NCS was collected and washed with THF (CAS No: 109-99-9) by repeated Soxhlet extraction. The NCS yield was 82%.

[0030] Then NCS (253 mg) was mixed with 0.15M lithium bistrifluoromethanesulfonimide (LiTFSI, CAS number: 90076-65-6) to obtain a mixture NCS-LiTFSI, and dried in a vacuum oven at 60°C for 12 hours, then in N 2 It was calcined for 3 h under the atmosphere, and then pressed into tablets. The yield of NCS-LiTFSI was 95%.

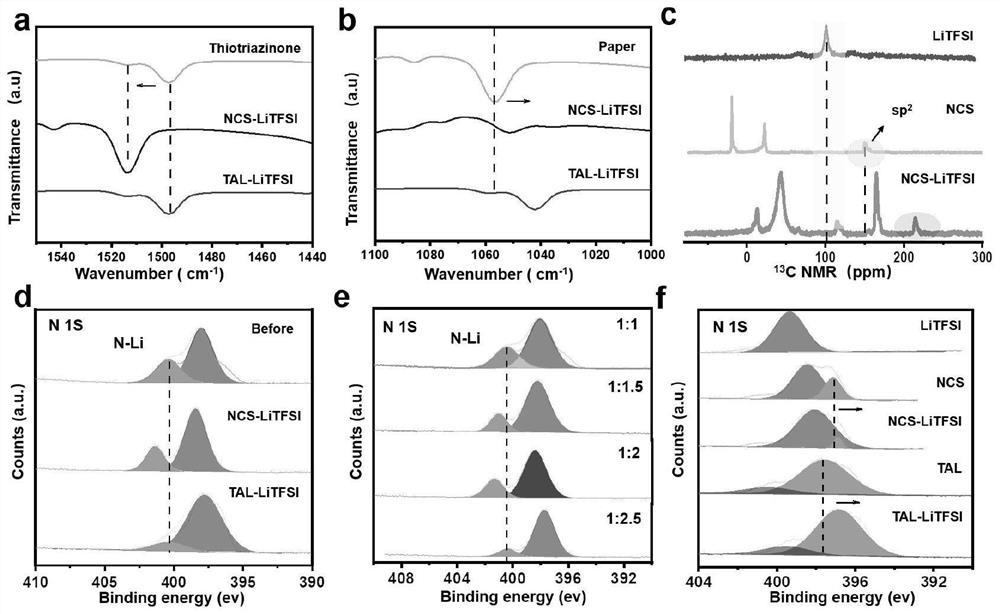

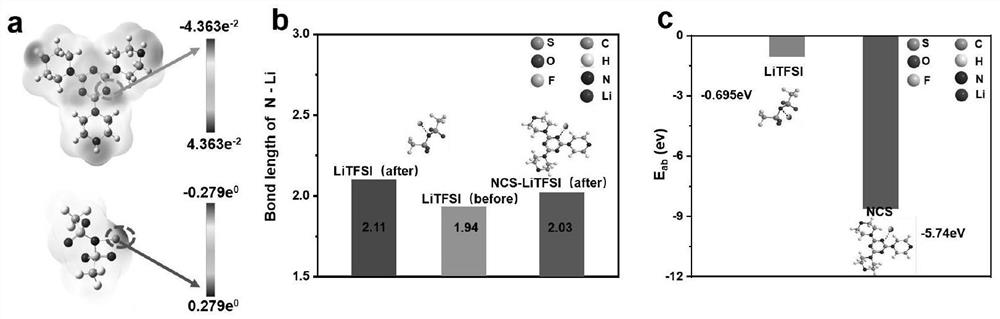

[0031] First, the chemical structure of NCS was obtained using FTIR spectroscopy and 13 C soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com