A wire automatic stripping and cutting machine

A technology of stripping and cutting machine and wire, applied in mechanical equipment, transmission device, gear transmission device, etc., can solve the problem of wire stripping and cutting too long, and achieve the effect of light weight, small structure and neat wire cutting section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

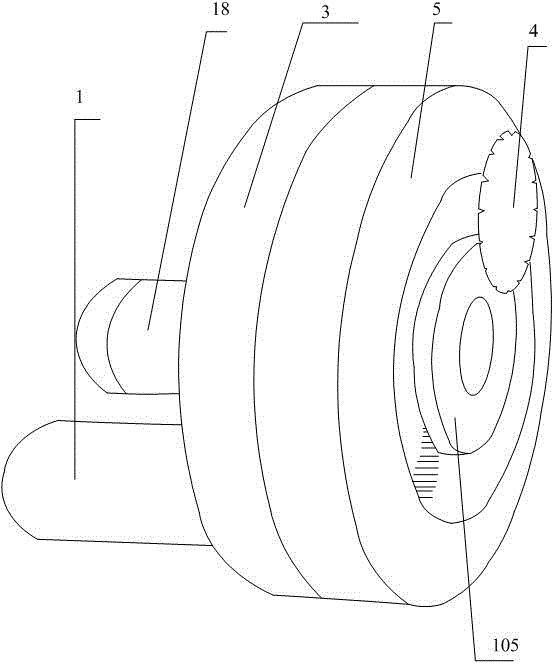

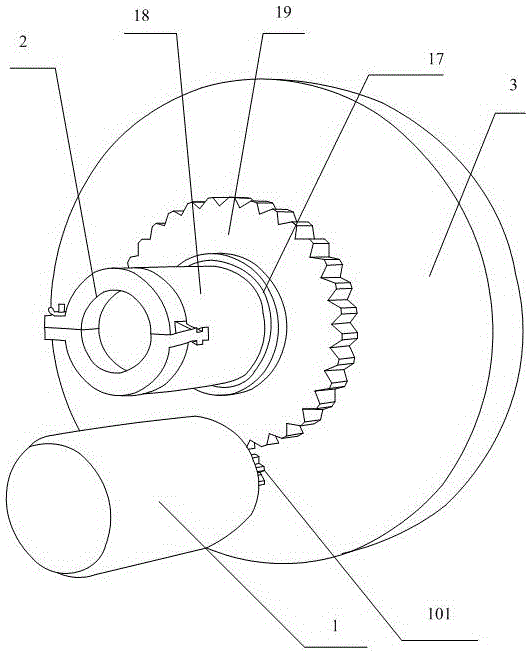

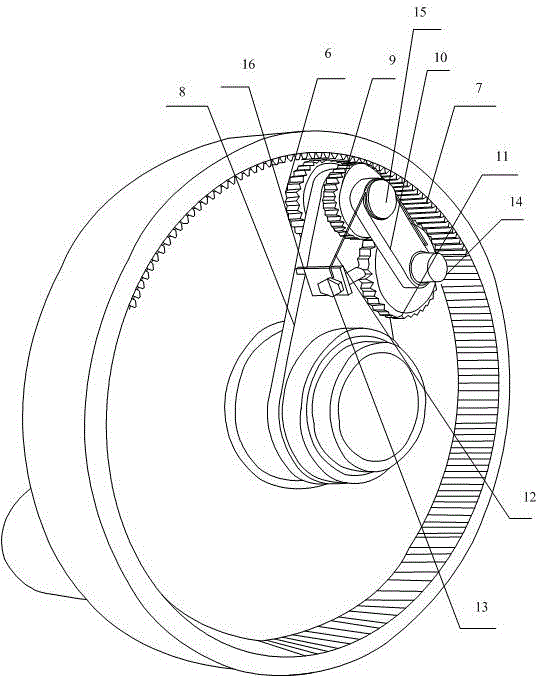

[0021] Such as Figure 1 to Figure 3 shown.

[0022] An automatic wire stripping and cutting machine, comprising a fixed disc 3, a main shaft 18 passing through the fixed disc 3, the outer diameter of the main shaft 18 is provided with a bearing 17, the outer diameter of the bearing 17 is provided with a large swing arm 8, and the large swing arm is far away from the bearing One end of 17 is provided with a through main shaft 15, one end of the fixed disc 3 is a closed end, the other end of the fixed disc 3 is an open end, the fixed disc 3 is a hollow cylinder, and the inner diameter surface of the fixed disc 3 is provided with internal teeth 7, The side of the large swing arm facing the closed end of the fixed disc 3 is provided with a planetary driving gear 6, and the side of the large swing arm facing the open end of the fixed disc 3 is provided with a planetary driven gear 9, and the planetary driven gear 9 and the planetary driving gear 6 are both It is sleeved on the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com