Aluminum wire layer stripper

A stripper, aluminum wire technology, used in cable installation devices, electrical components, equipment for dismantling/armoring cables, etc. The effect of fast cutting speed, compact structure design and not easy to loose strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

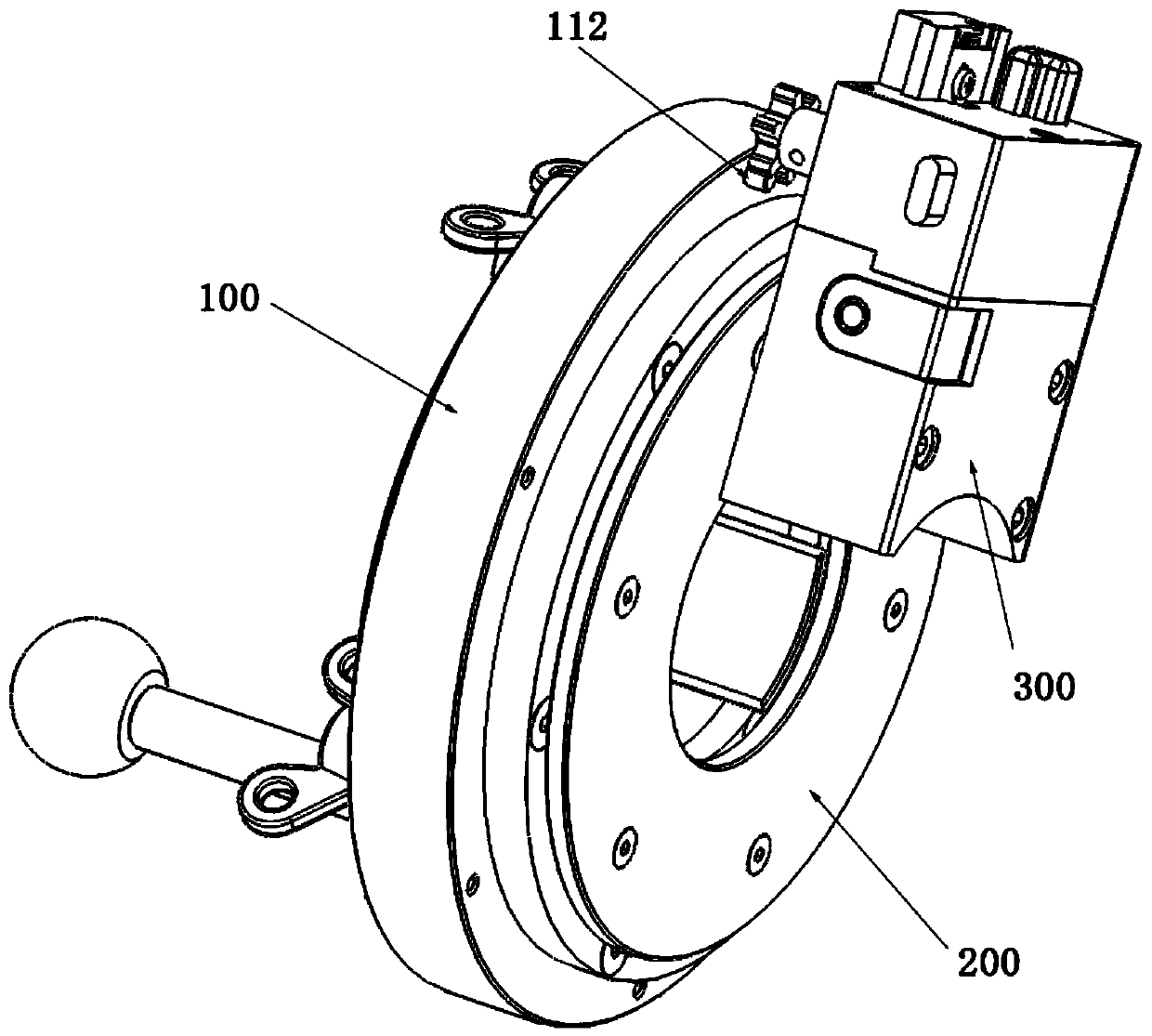

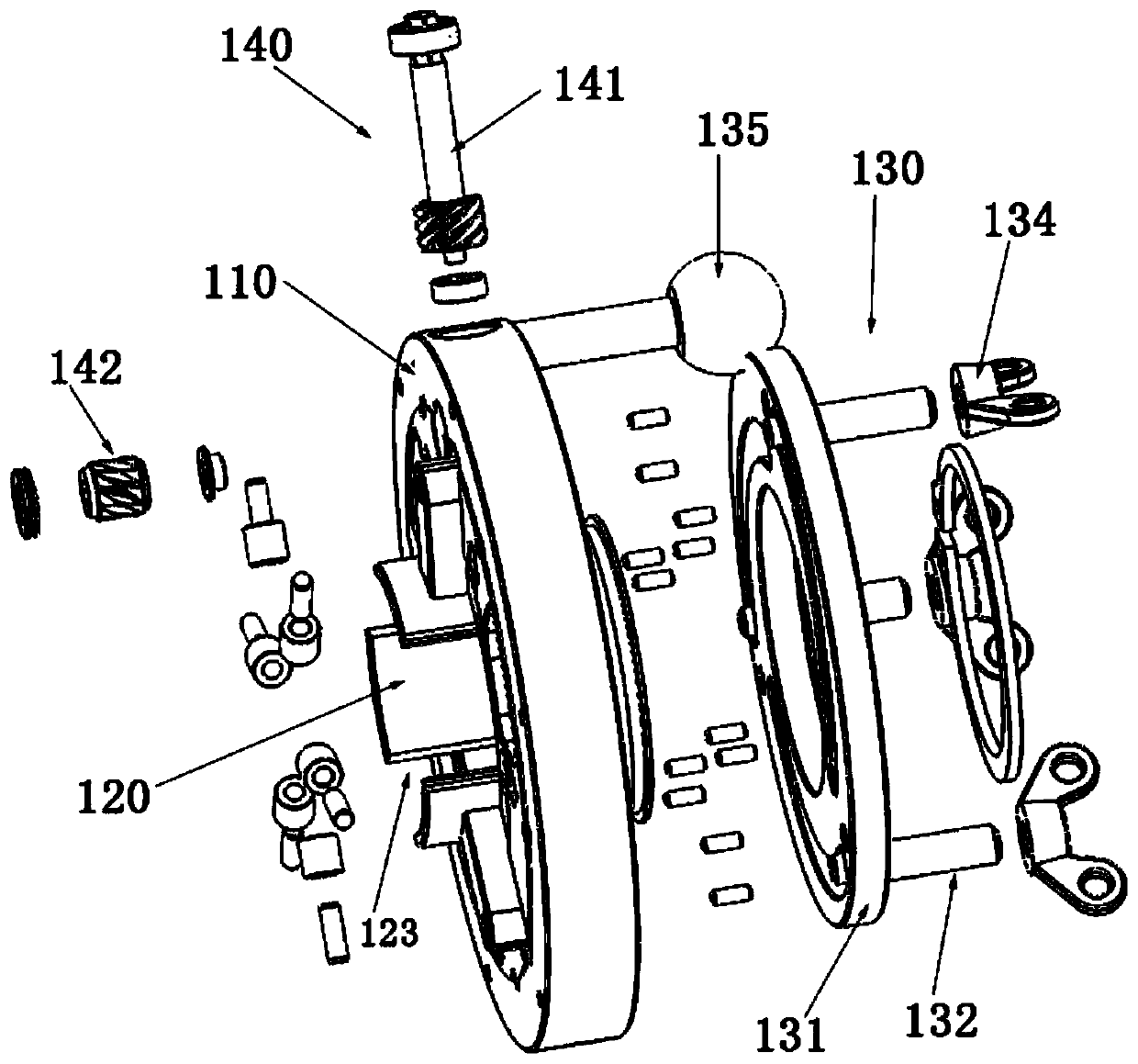

[0033] Such as figure 1 with figure 2 As shown, this embodiment provides an aluminum wire layer stripper, which includes a clamping device 100, a rotating device 200, and a cutting device 300. The main function of the clamping device 100 is to clamp the cable and fix it on the cable. The rotating device 200 connects the clamping device 100 and the cutting device 300 and can rotate on the clamping device 100. The cutting device 300 passes through the rotating device 200. Drive the rotation to cut the outer aluminum wire layer of the cable.

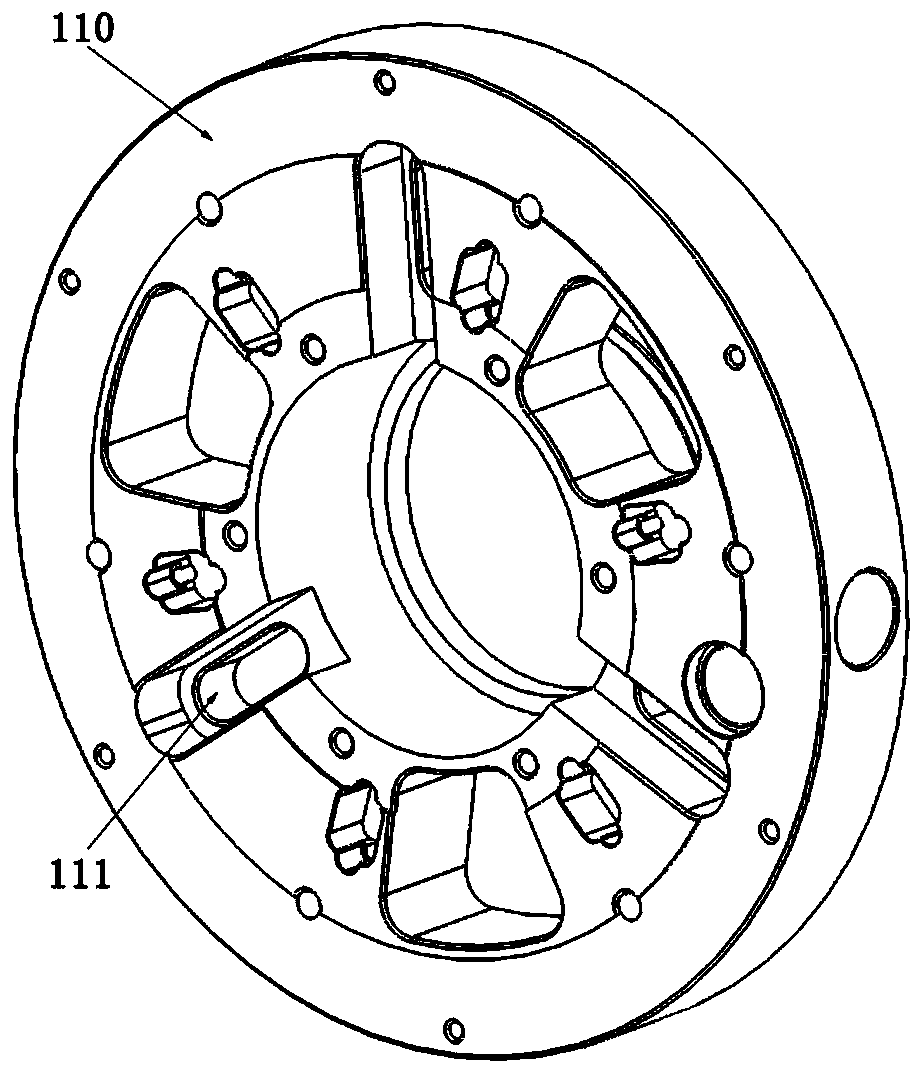

[0034] The clamping device 100 includes an annular main body 110, a plurality of clamping members 120, and a clamping opening adjustment mechanism 130. The plurality of clamping members 120 are evenly spaced around the center of the circular main body 110. The clamping members 120 and the circular main body 110 are arranged in a radial direction. In a sliding connection, the lower ends of the plurality of clamping members 120 respectively ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com