A blanking device for a punching machine in an upsetting workshop

A punching machine and workshop technology, applied in the field of punching machine blanking device in the upsetting workshop, can solve the problems of waste of raw materials, production cost of turning tool damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

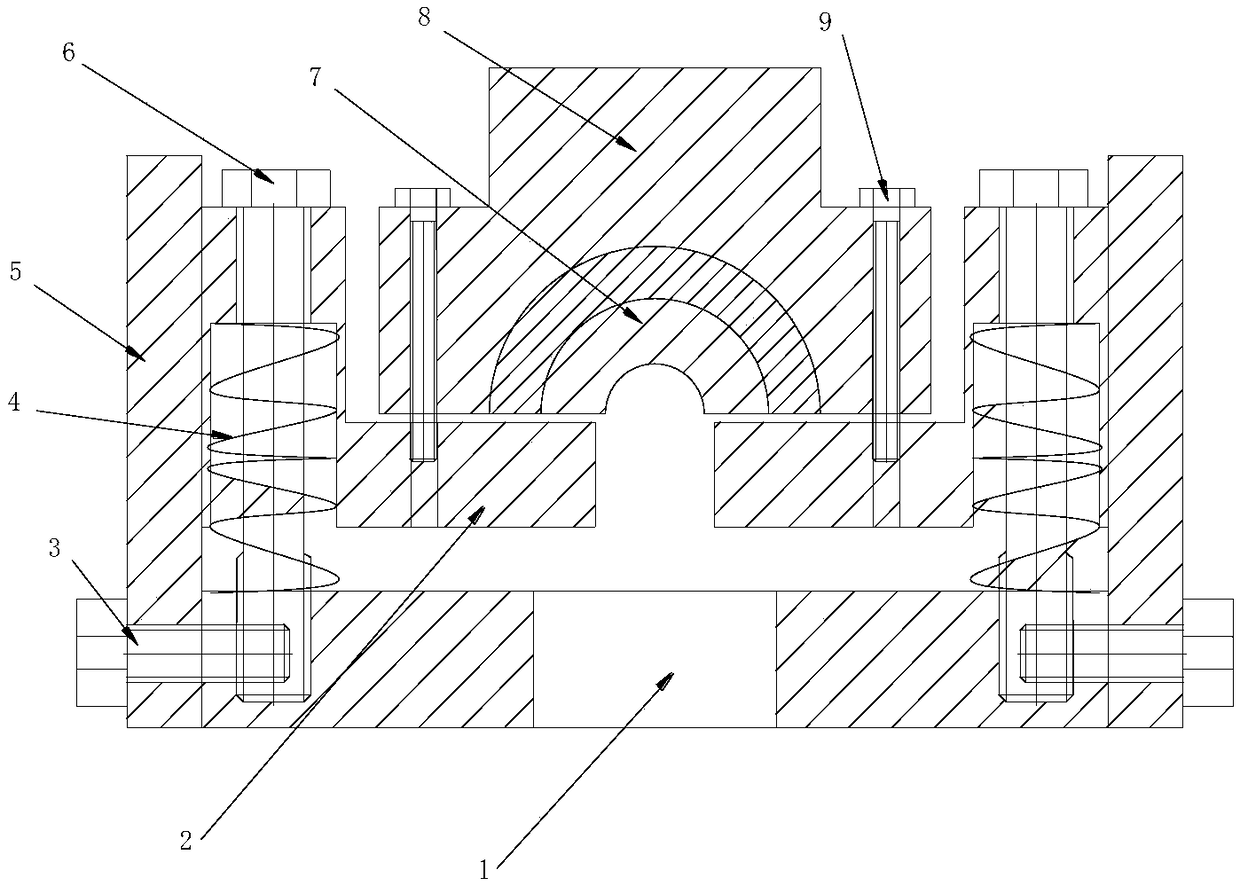

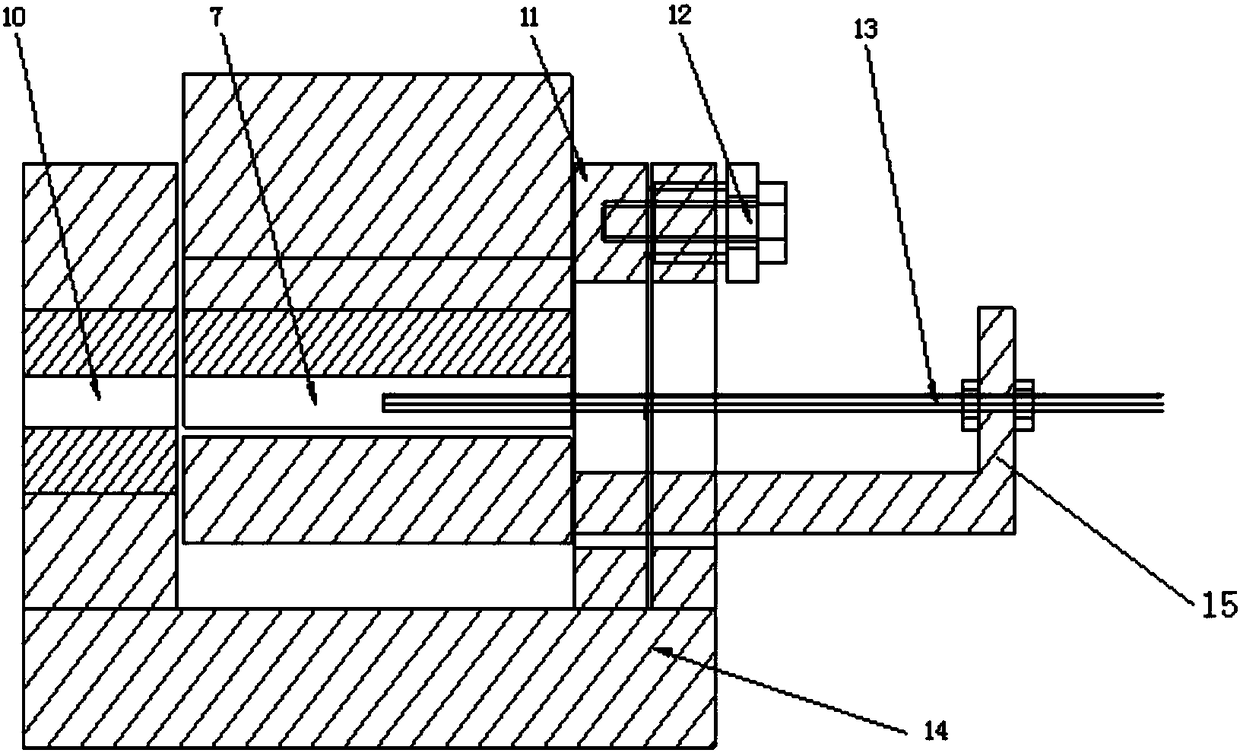

[0017] The present invention is a blanking device for a punching machine in an upsetting workshop, the structure of which is as follows: figure 1 As shown, it includes a half circular semicircle cutter 7 placed vertically, the blade of the semicircle cutter 7 is located on the inner arc, and the two ring sections of the semicircle cutter 7 are also located at a pair of limit positions respectively. On the sliding block 2, the outer arc of the semicircle cutter 7 is matched with a semicircle cutter fastening module 8, the bottom surface of the semicircle cutter fastening module 8 and the two ring sections of the semicircle cutter 7 are coplanar, and the semicircle cut The knife fastening module 8 is also connected with the pair of limit sliding blocks 2 through the module fastening bolts 9, and a pair of limit sliding blocks 2 are also respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com