Auger bit with highly-spiral land

A technology of twist drill and helical edge, which is applied in the direction of twist drill, etc., can solve the problems of low straightness and position of twist drill, achieve the effect of increasing the length of the margin, increasing the helix angle of the margin, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

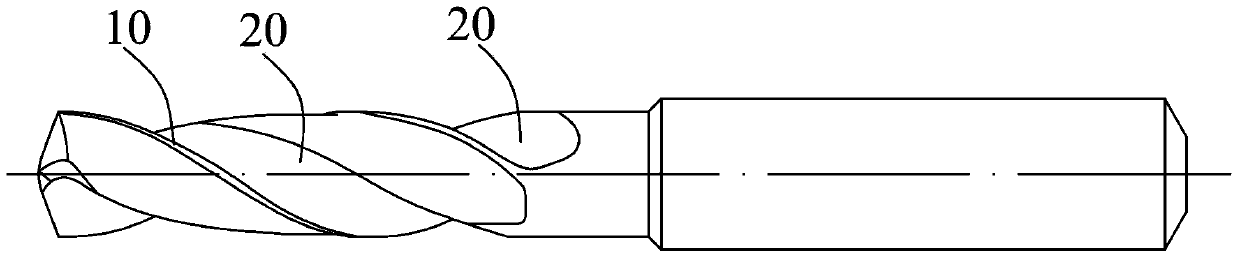

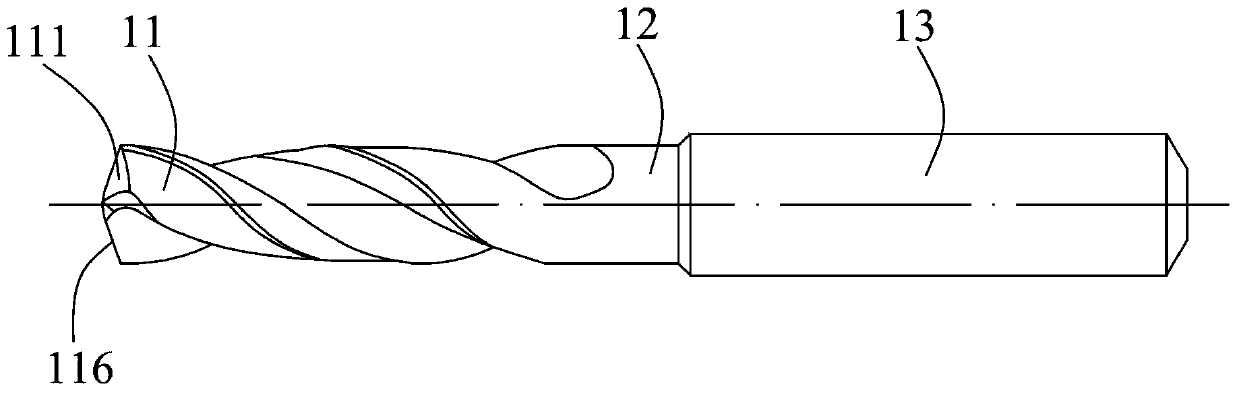

[0027] Such as figure 2 Shown is a twist drill with a high helical margin according to the present invention, which includes a head 11 , a shank 13 and a neck 12 between the head 11 and the shank 13 . The head 11, the neck 12 and the handle 13 are coaxial cylinders centered on the same central axis. The diameter of the shank 13 is greater than the diameter of the neck 12 . The shank 13 is a section of cylinder with high cylindricity, and the external collet clamps the shank 13 to transmit the power of the machine tool, so that the head 11 can rotate to have cutting ability.

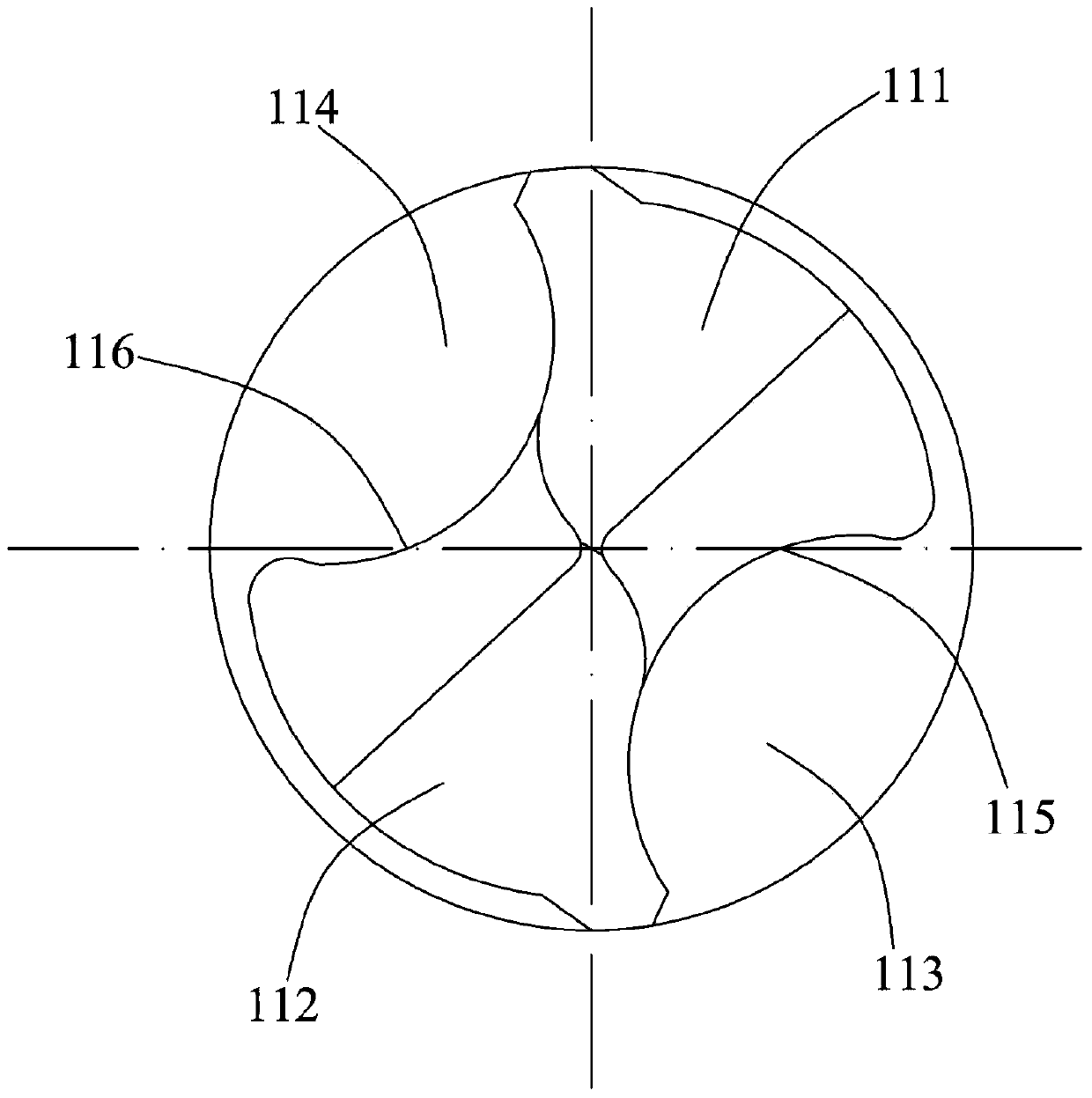

[0028] Such as figure 2 and image 3 As shown, the front end of the head 11 is provided with a first tip 111 and a second tip 112 for drilling. The first tool tip 111 and the second tool tip 112 extend spirally along the circumferential direction with the central axis as the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap