Preparation method of throw-away drill and throw-away drill

A discarded drill bit technology, applied in twist drills and other directions, can solve the problems that the height of the cutting blade cannot be too small, the helix angle of the chip flute cannot be achieved, and the cutting blade is prone to shaking. The method is simple and feasible, and the strength is enhanced. The effect of maintaining work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

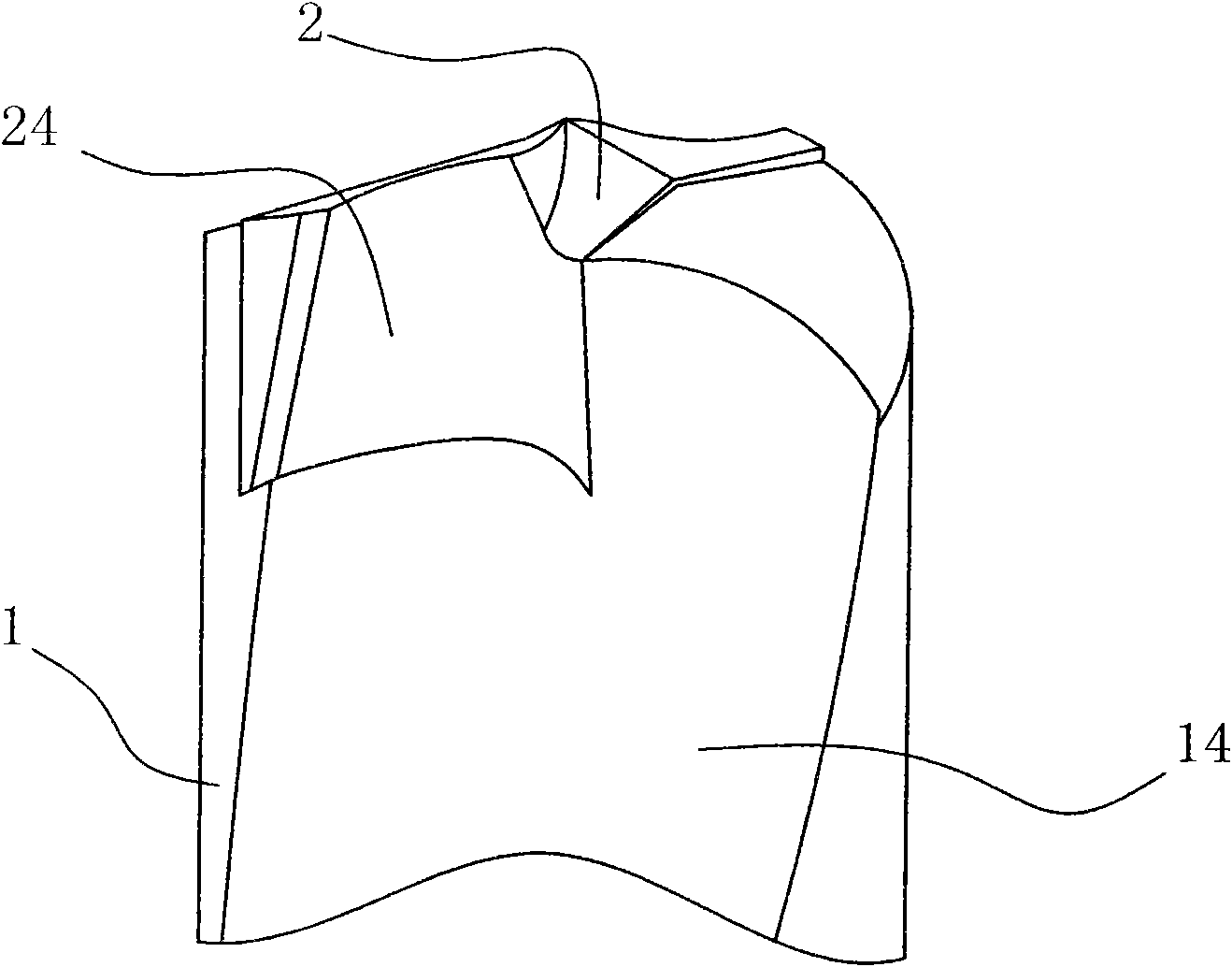

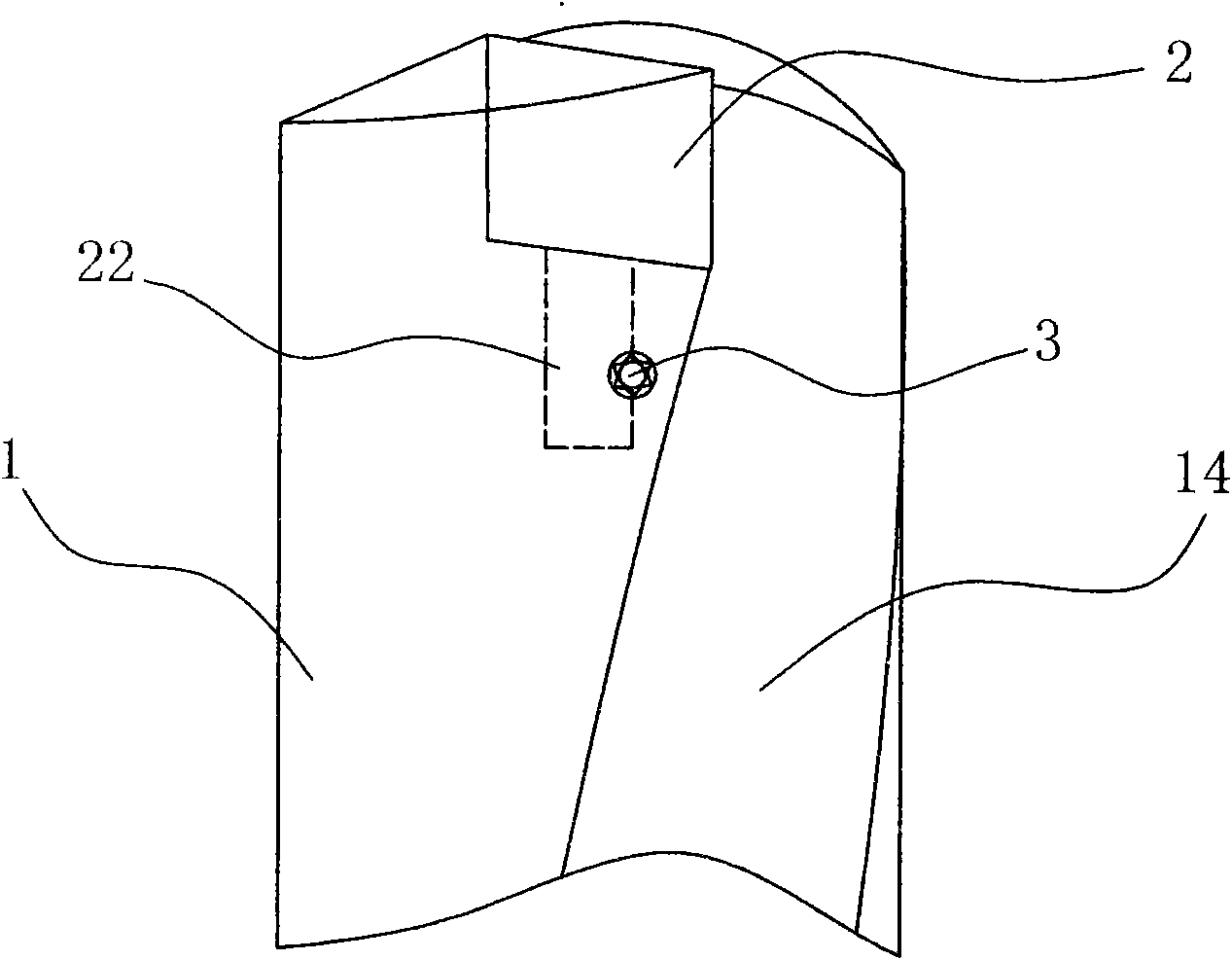

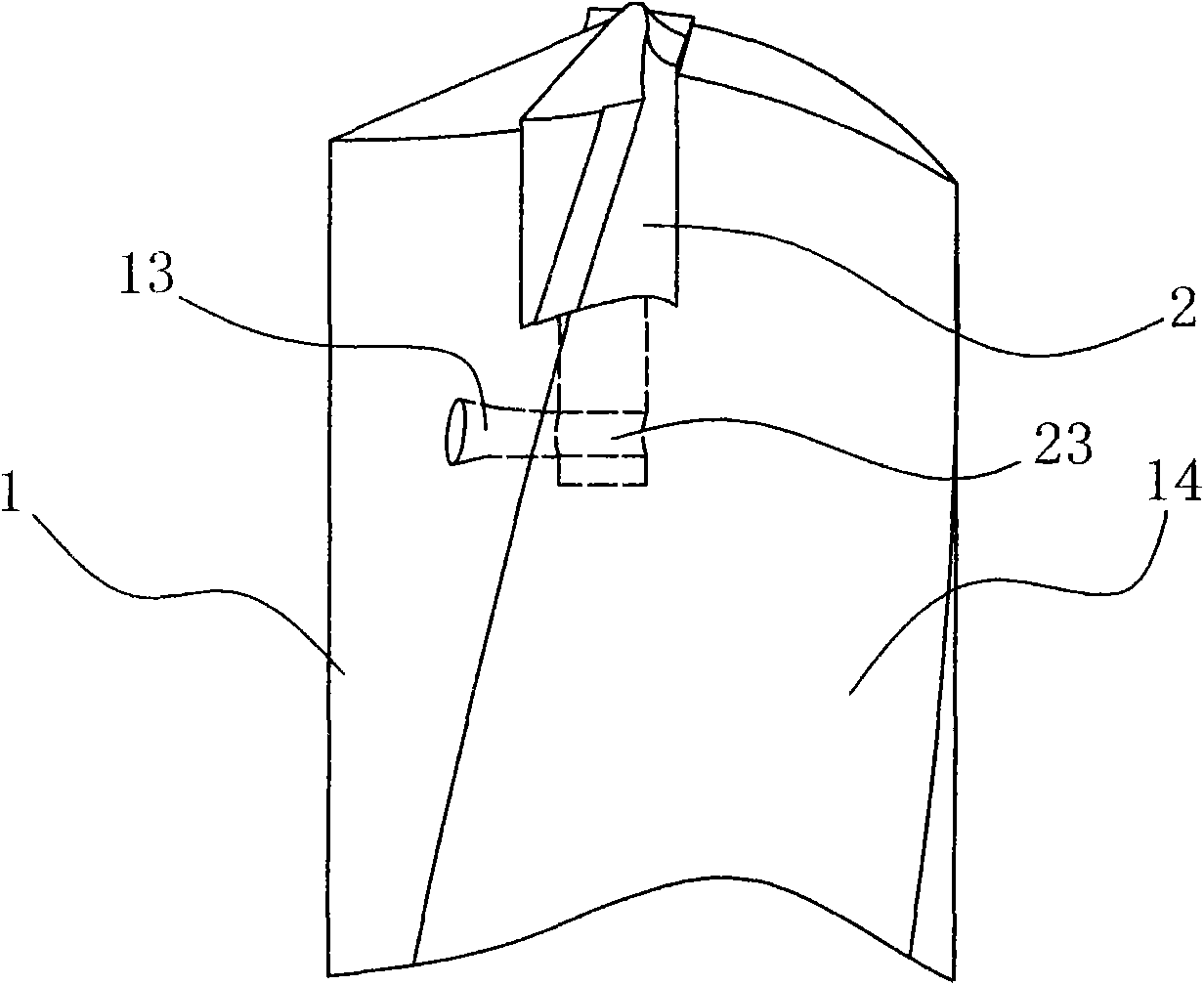

[0032] Example: see Figure 1 to Figure 7 , a method for preparing a discarded drill bit of the present invention, which comprises the following steps:

[0033] (1) Prepare a drill body 1, set a groove 11 horizontally in the middle of the cutting end of the drill body 1, and set a positioning hole 12 at the bottom of the groove 11, and the positioning hole 12 is located on the central axis of the drill body 1 ;

[0034] (2) prepare a cutting blade 2, the cutting blade 2 includes a cutting blade body 21 and a positioning post 22 arranged at the bottom of the cutting blade body 21, the cutting blade body 21 can be inserted into the groove 11 and closely fit, The positioning column 22 is matched with the positioning hole 12;

[0035] (3) Insert the cutting blade 2 into the groove 11, fix the cutter body 21 to the drill body 1 by making structural improvements on the positioning column 22 and the drill body 1, avoiding the The main body 21 is provided with locking holes for fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com