Method for manufacturing drill bit with cutting tool bit replaceable and product thereof

A technology of cutter head and drill bit, which is applied in the direction of drilling/drilling equipment, drill repairing, drilling tool accessories, etc., can solve the problems of waste of materials and money, difficulty in popularizing and using drill types, etc., to reduce material waste, reduce processing costs, The effect of prolonging tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

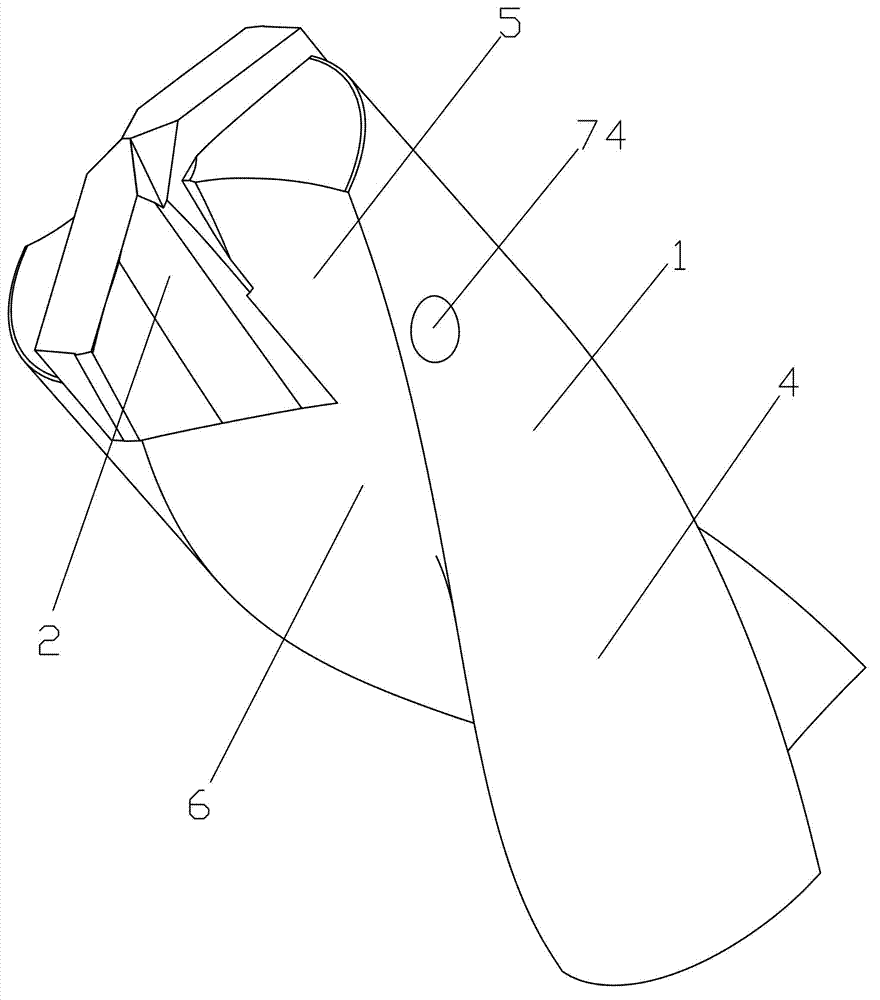

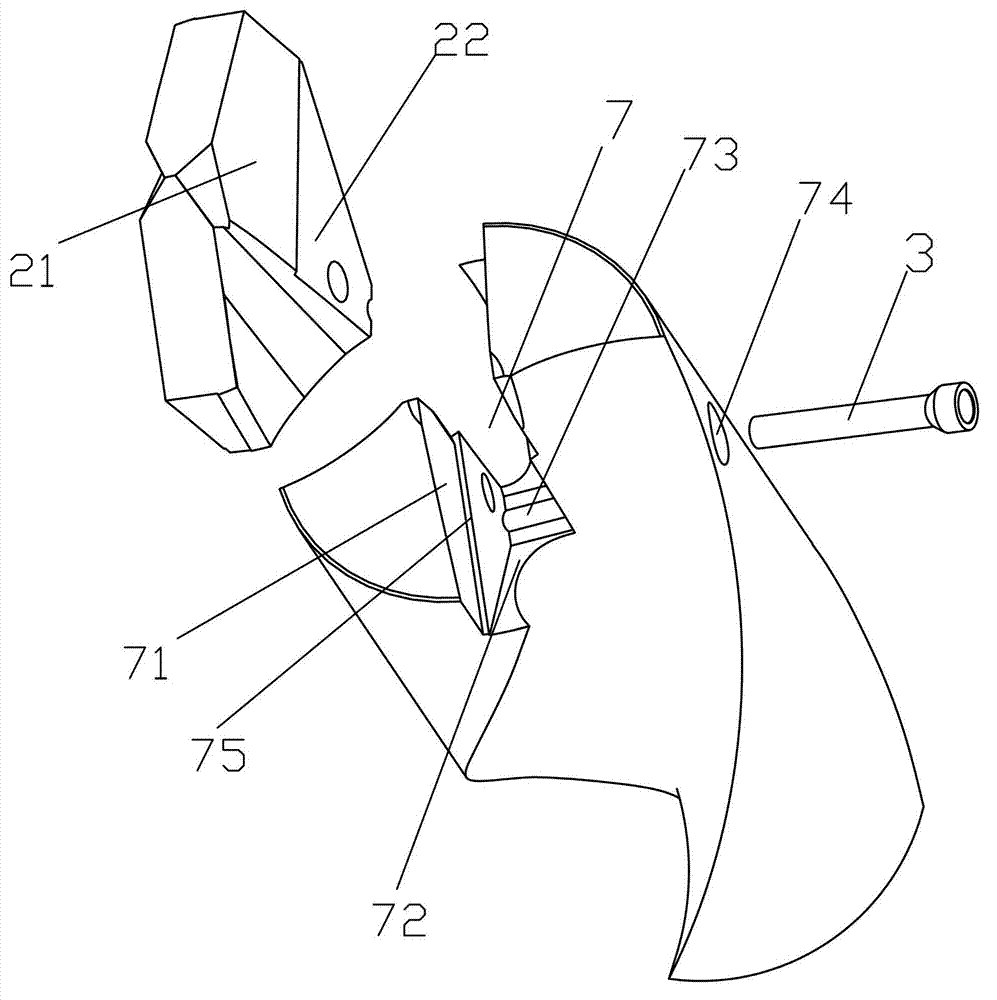

[0024] see Figure 1 to Figure 3 , a method for preparing a drill bit with a replaceable cutting bit provided in this embodiment, comprising the following steps:

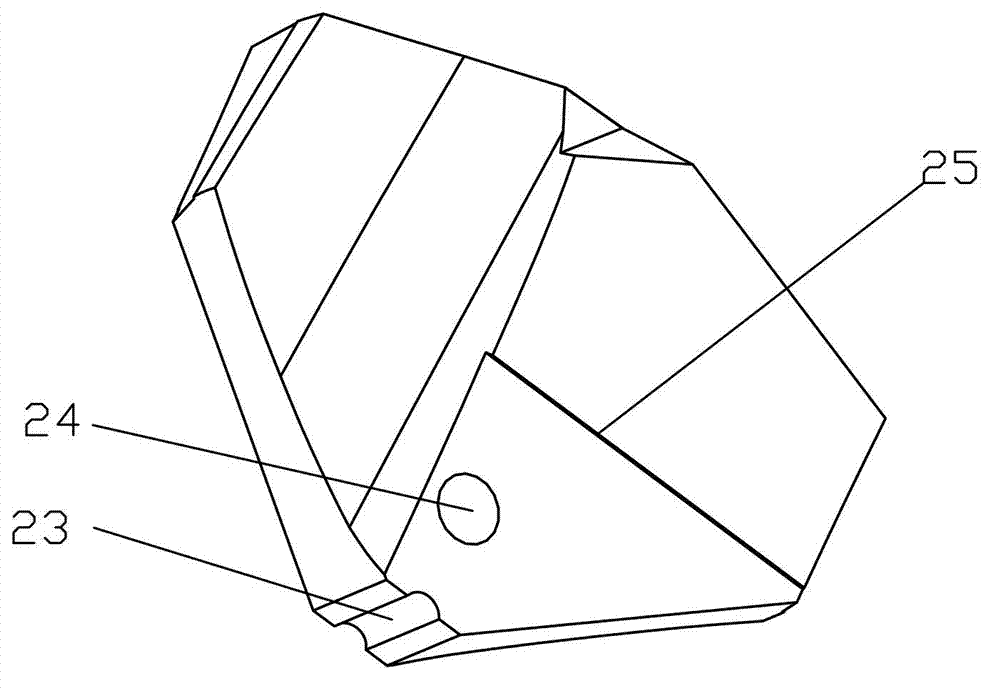

[0025] 1) Prepare a drill body 1: set a shank 4 and a working part 5; set a chip removal groove 6 on the working part 5, and set a cutter head fixing groove 7 horizontally at the front end; a part of the cutter head fixing groove 7 falls into the working part 5 The flute part of the flute 6, another part falls into the back of the working part 5, and is composed of the upper blade flute 71 and the lower part groove 72 consisting of the The cross section of type groove 72 is positioned at the middle part of working portion 5 cross sections; An arc-shaped protruding positioning block 73 is arranged in the middle of the bottom of the groove 72; the chip removal groove 6 is two straight or spiral chip removal grooves.

[0026] 2) Prepare a cutting bit 2 compatible with the bit fixing groove 7: set a cutting part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com