Sealing structure of vertical air cooling cabinet and modification method thereof

A closed structure, air-cooled cabinet technology, applied in the direction of sealing device, wing fan arrangement, etc., can solve the problems of cold air loss, large power consumption, etc., to achieve the effect of preventing the outflow of cold air, saving electric energy, and filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

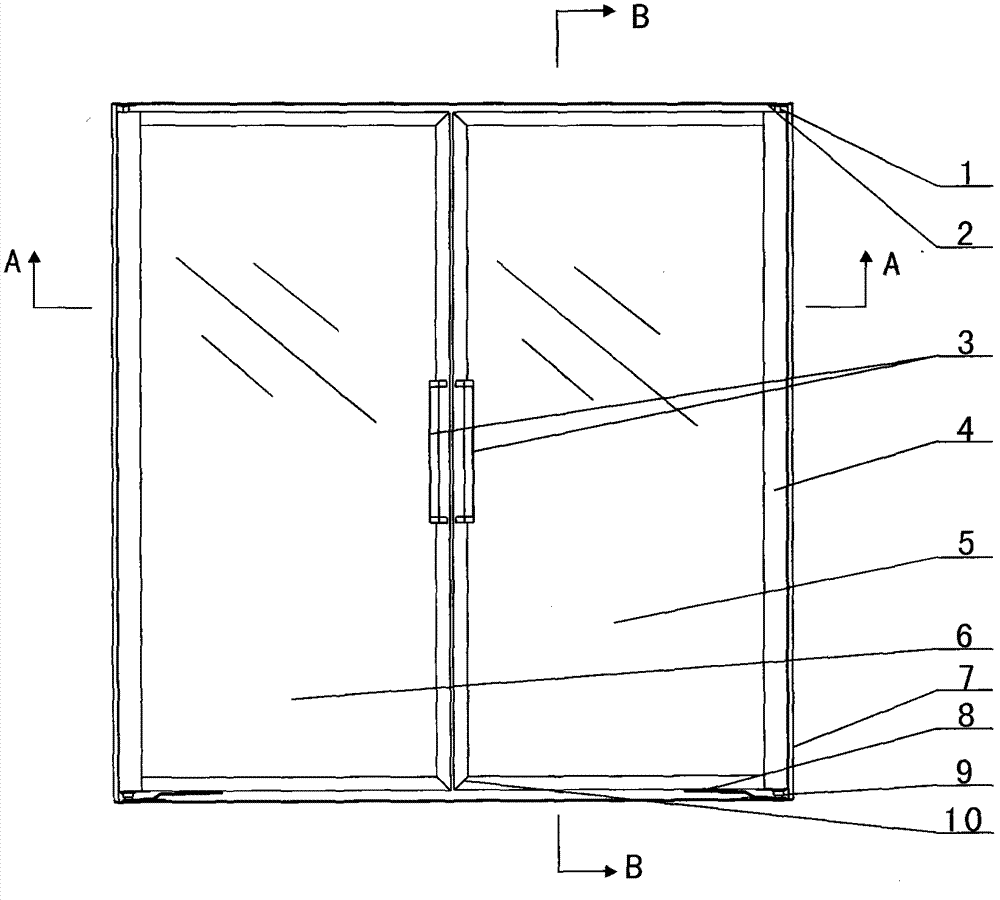

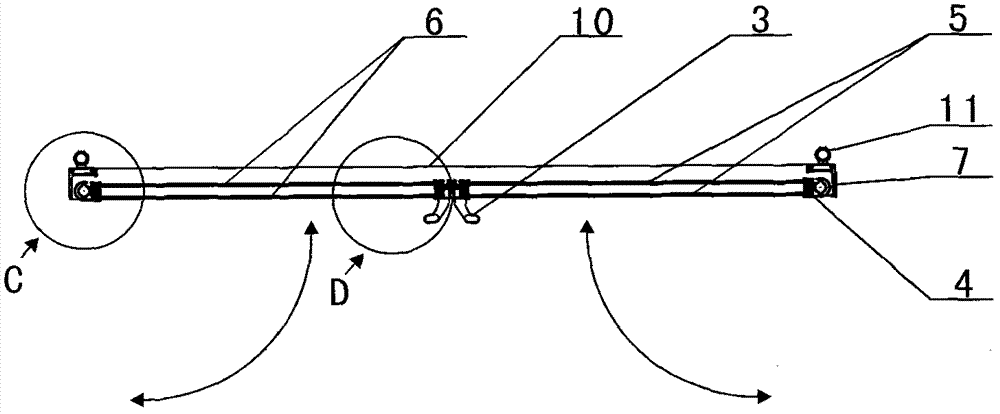

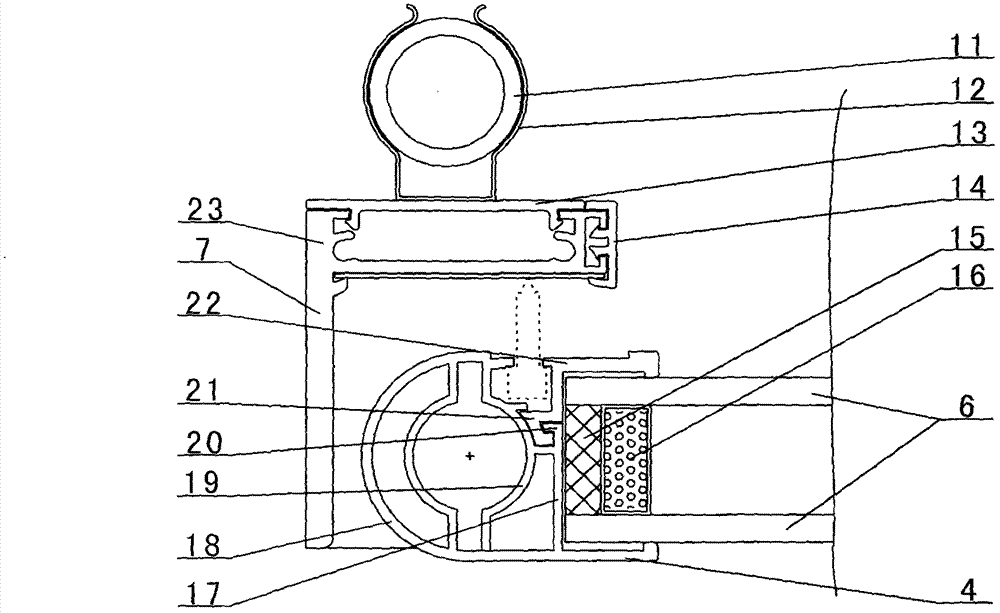

[0036] combined with Figure 1-7 The closed structure of the vertical air-cooled cabinet includes the front opening of the air-cooled cabinet, the connecting frame 7, double glass doors, the upper shaft 1 and the lower shaft 9, and the upper and lower ends of the connecting frame 7 are respectively connected to the front opening of the air-cooled cabinet The upper cabinet body 39, the lower cabinet body 38 and the left and right cabinet sides are provided with at least one double glass door in the connecting frame 7, and the upper shaft 1 and the lower shaft 9 arranged up and down on one side of the double glass door pass through respectively The hinge plate 2 is connected up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com