Air compressor energy-saving control method

An energy-saving control and air compressor technology, applied in pump control, mechanical equipment, machines/engines, etc., can solve the problems of frequent opening and closing of intake valves, inability to meet process requirements, and single working mode, and achieve good energy-saving effects, Improve the protection function and ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

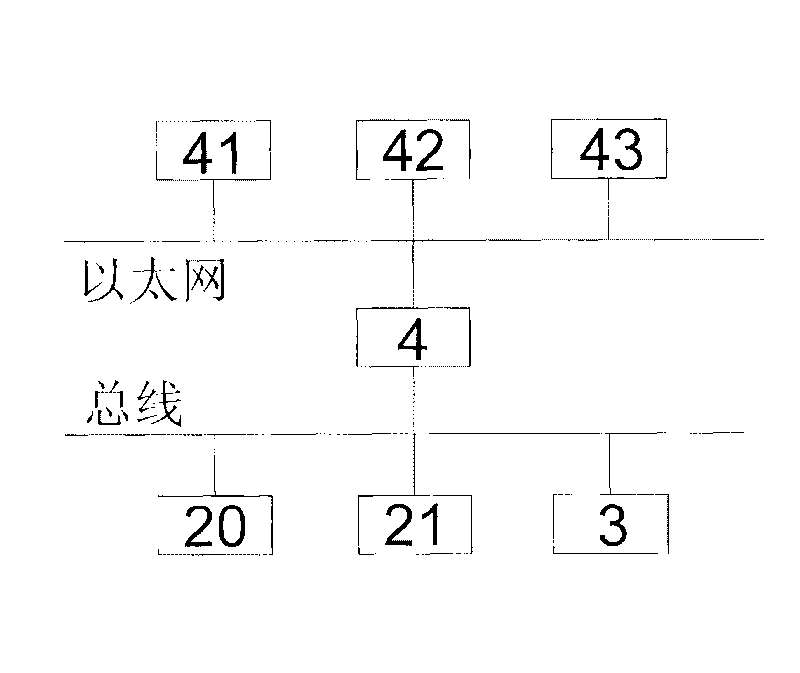

[0019] The invention provides the motor with two working modes of power frequency start and variable frequency start, and the control circuit switches the two modes. Among them, in the frequency conversion working mode, the pressure value in the gas storage tank is sampled, and the output of the frequency converter is dynamically adjusted to achieve the purpose of energy saving. The whole system adopts DCS (Distributed Control System, also known as Distributed Control System) to monitor and manage the air compressor flexibly.

[0020] combine figure 1 , figure 2 and image 3 The implementation of the present invention is further described in detail.

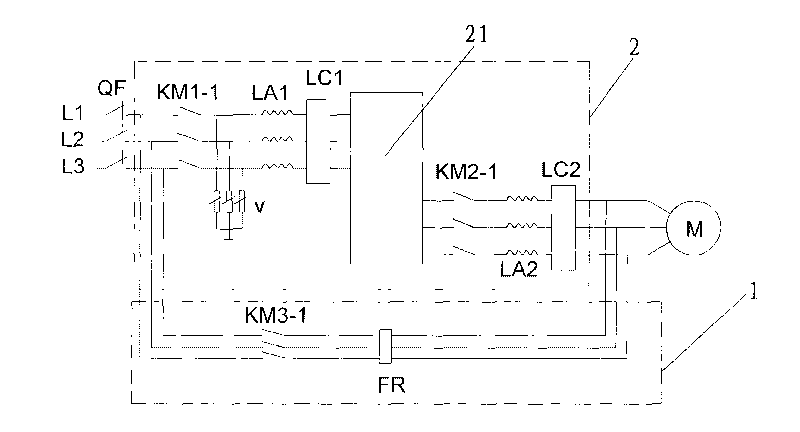

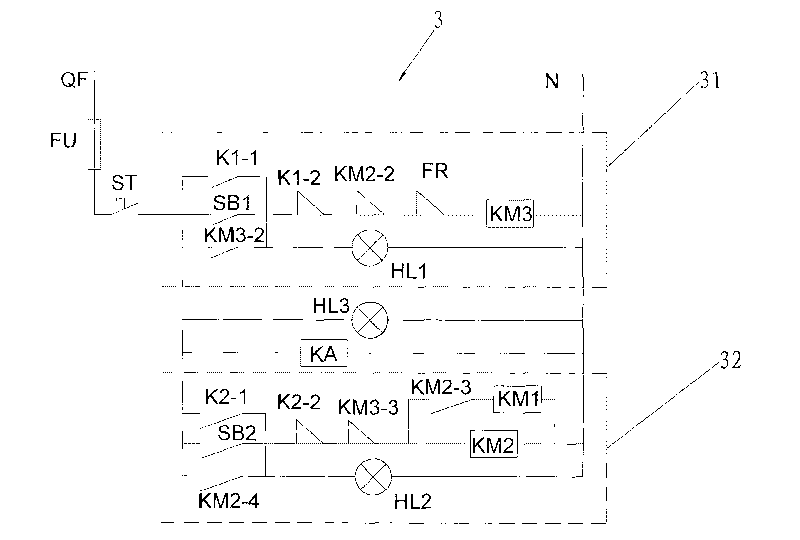

[0021] The main circuit of the motor of the present invention is to connect the power frequency starting branch 1 and the frequency conversion starting branch 2 in parallel after the air switch QF, and a control circuit 3 is connected between the two ends of the air switch QF and N, and the control circuit 3 is mainly realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com