Phase change wall system capable of controlling storage and release of heat

A phase change and wall technology, applied in the field of building energy conservation, can solve the problems of high performance cost, high heat storage difficulty, selection and preparation difficulty, and achieve the effect of reducing heat demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

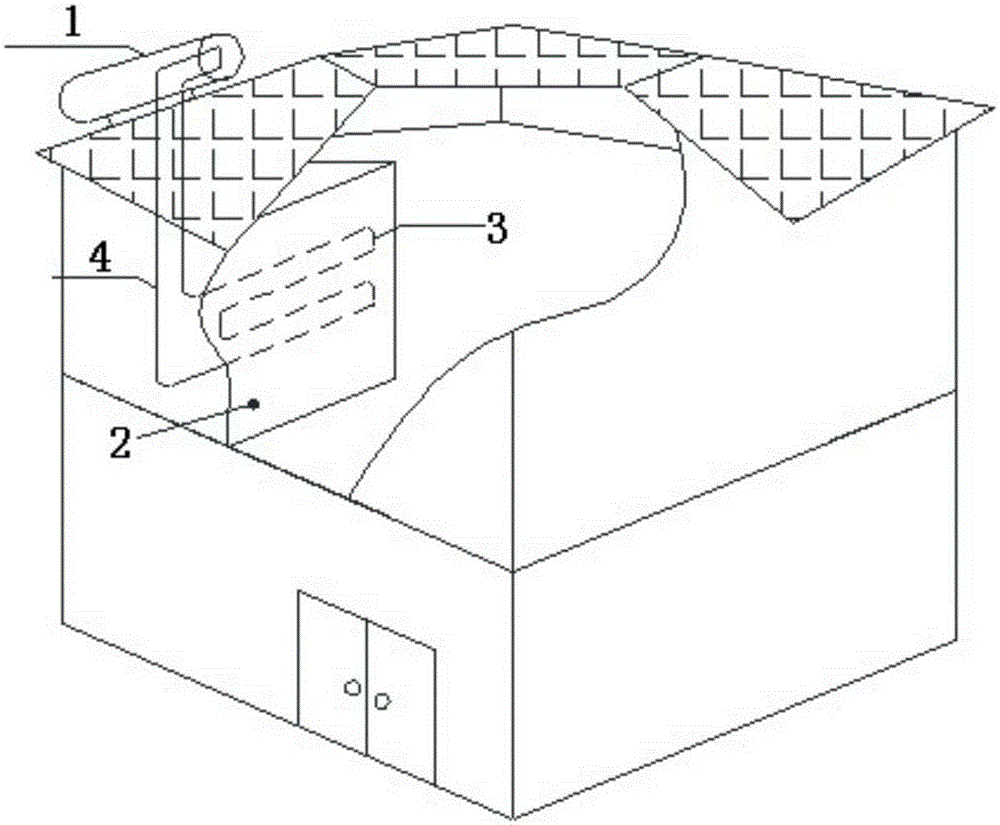

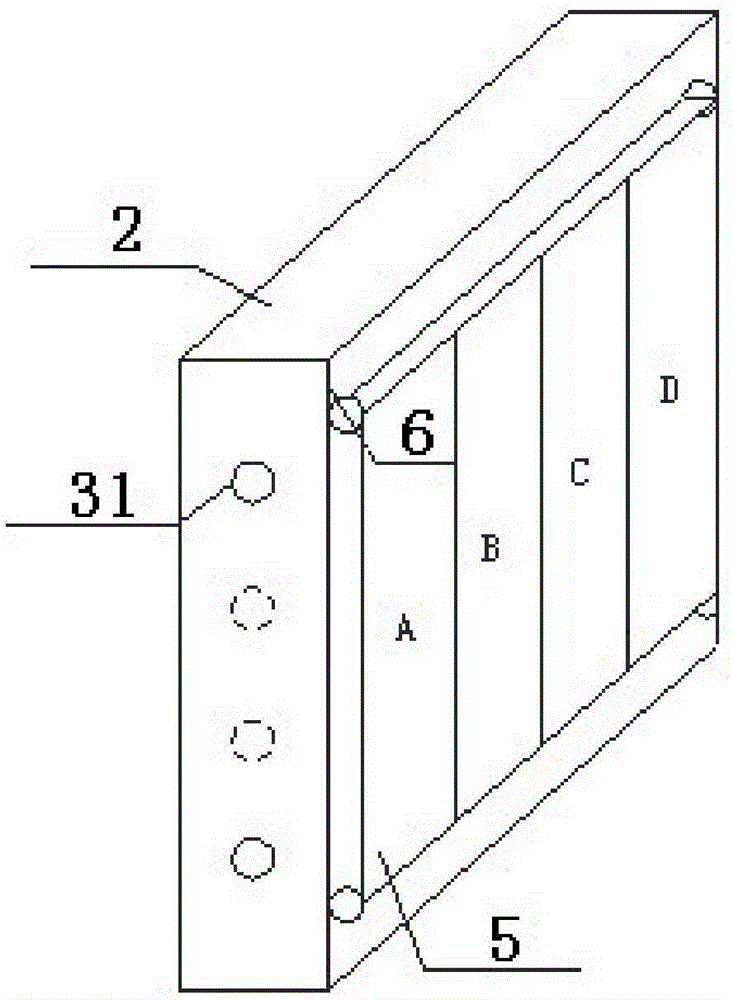

[0025] Such as figure 1 , 2 As shown, the phase change wall system of the present invention includes: a heat source device 1, a phase change wall 2, a heat exchange pipe 3, and a thermal insulation finish 4;

[0026] Wherein, the heat source device 1 is used for collecting hot water, and its two ends are connected with connecting pipes 6 .

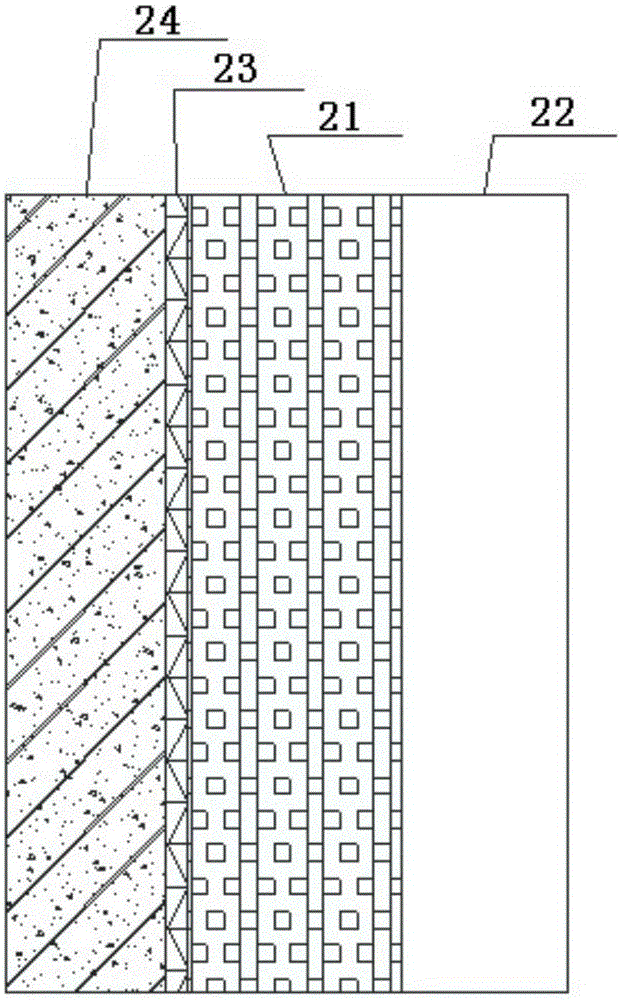

[0027] The interior of the phase change wall 2 is connected to the heat exchange pipe 3 connected to the heat source device 1, the phase change wall 2 absorbs heat from the hot water in the heat exchange pipe 3, and the phase change wall 2 contains a phase change material. The phase change wall body 2 stores and releases heat through the phase change process of the phase change material contained therein.

[0028] The heat exchange pipe 3 is connected with the connecting pipe 4 to form a closed pipe. The heat exchange pipe 3 is coiled in the phase change wall 2 to supply heat to the wall 2, and the connecting pipe 4 is connected to the ...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, only slightly different in the control of the thermal insulation finish. In order to better control the indoor heat release process, in this embodiment, the thermal insulation finish is divided into N pieces of small finishes of the same size or made into a form of venetian blinds. Users can choose the number of insulation finishes to remove the isolation phase change wall according to different thermal needs, increasing the flexibility of the entire system.

Embodiment 3

[0040] This embodiment is basically the same as Embodiment 1, only slightly different in the selection of thermal insulation facing materials. The thermal insulation finish material can choose rock wool board, EPS and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com