Alignment press-fit mechanism

A technology for aligning and pressing and pressing mechanism, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of inaccurate alignment, uncontrollable pressure and strength, and inability to ensure product quality, and achieve calibration. Precise, even pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

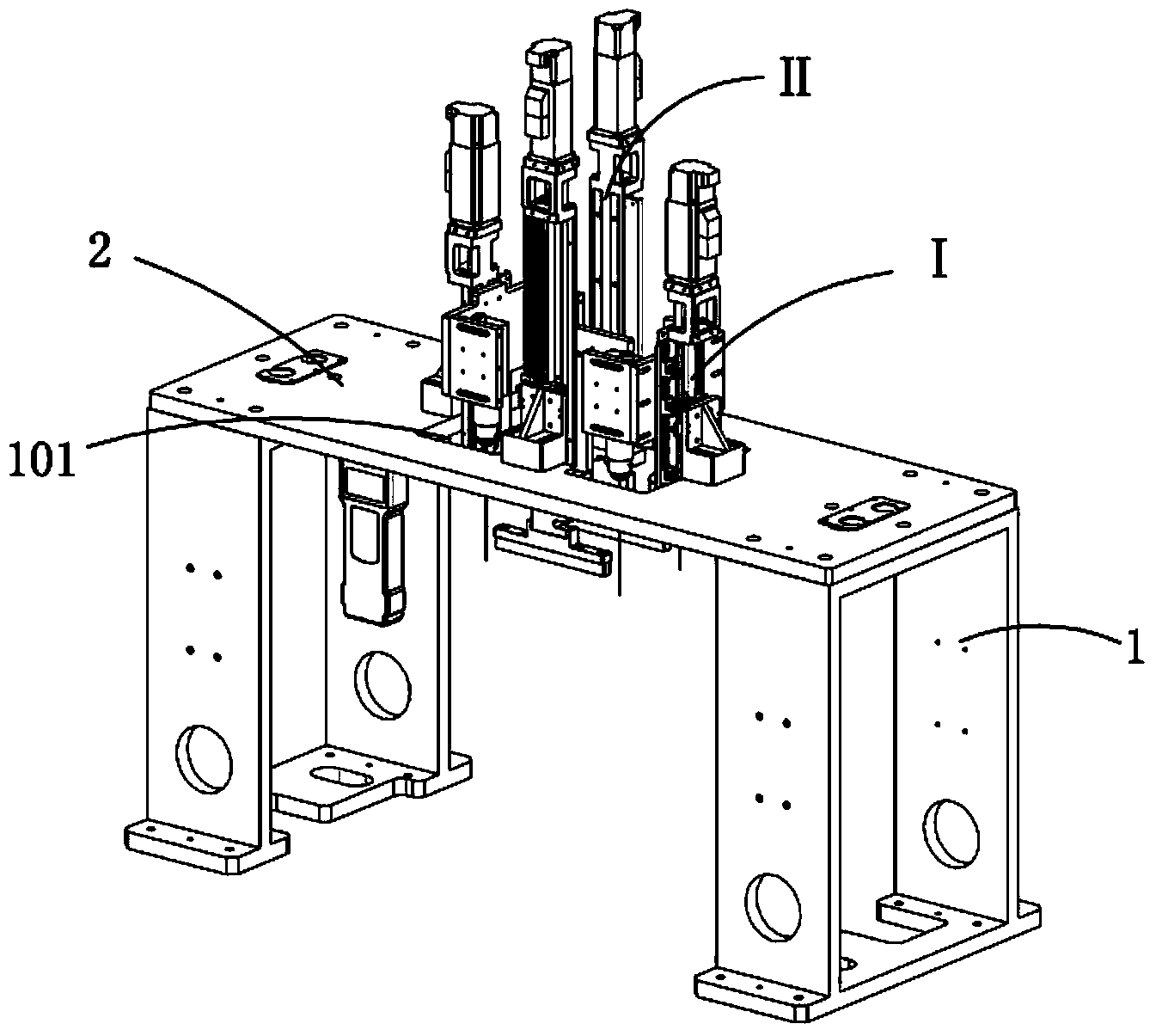

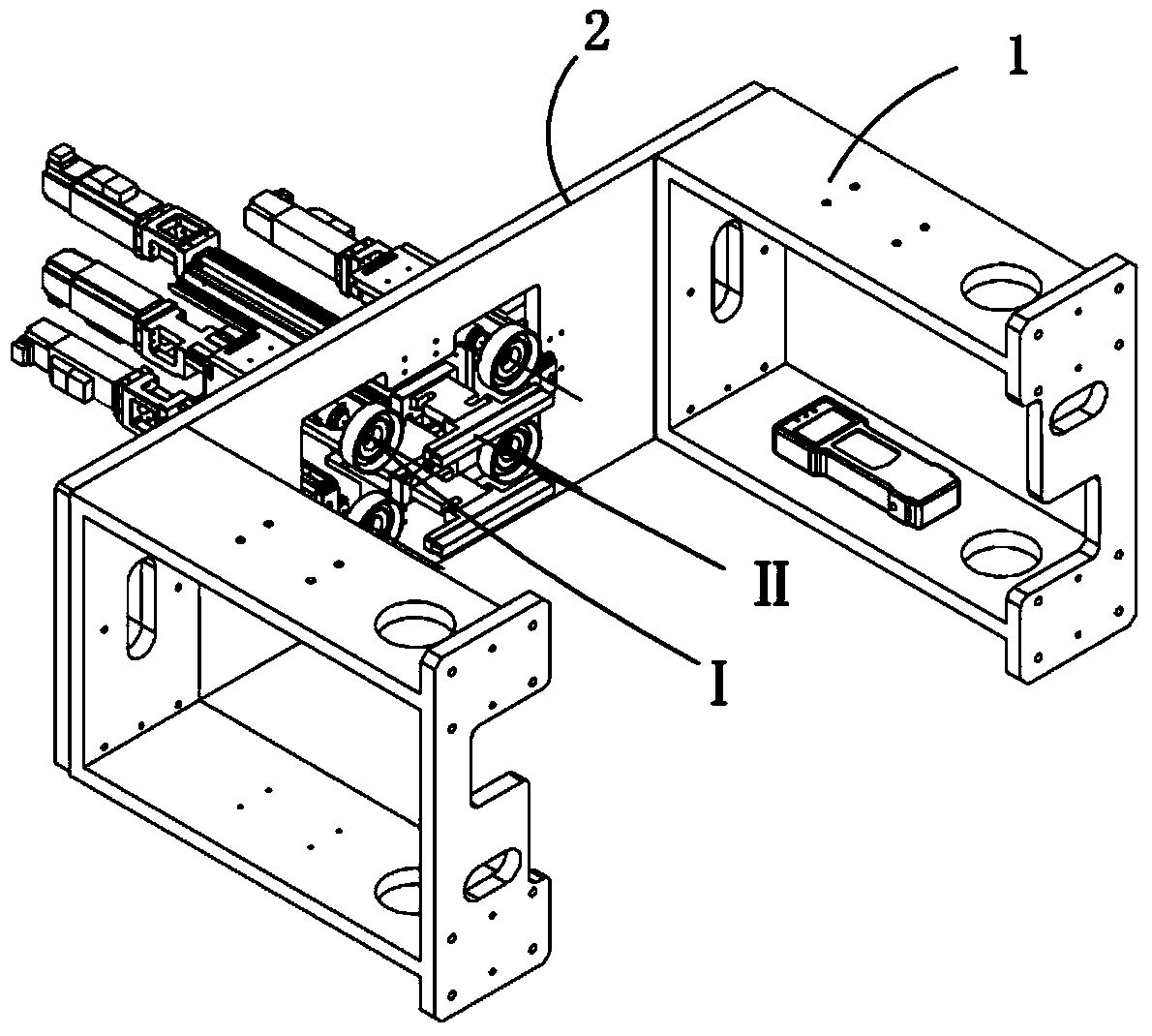

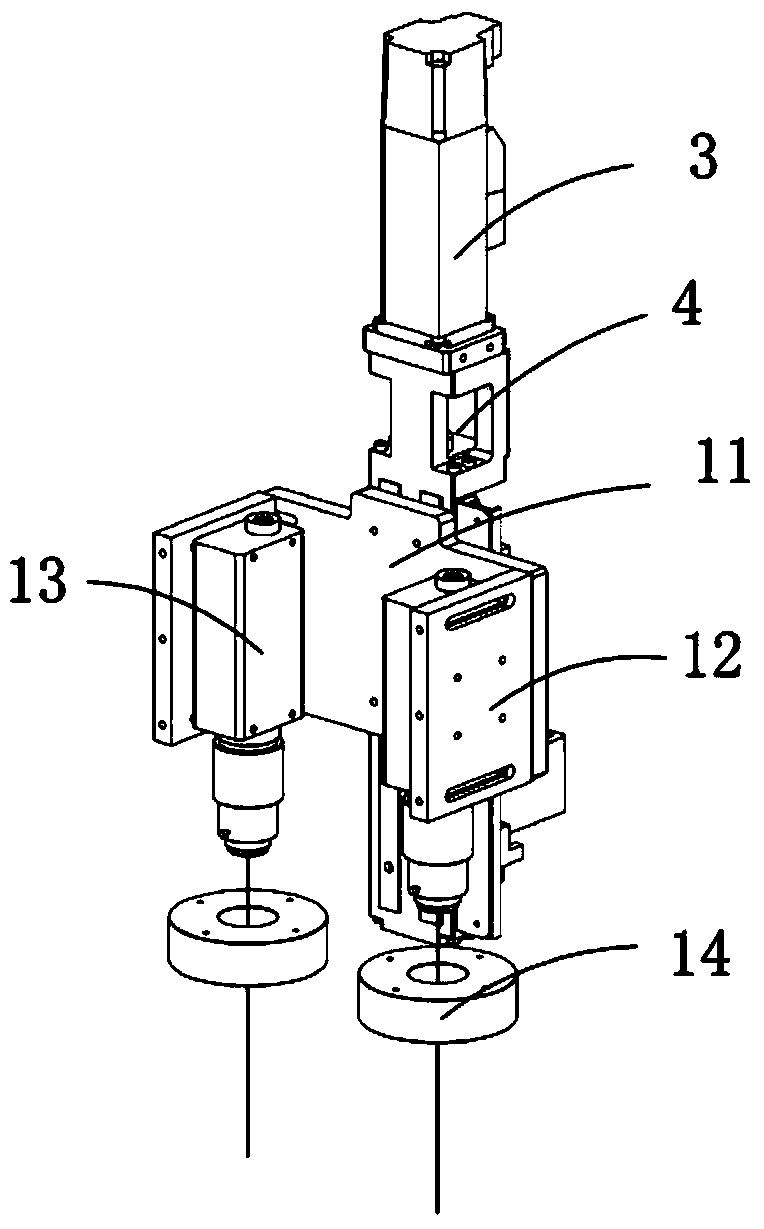

[0021] Examples, see attached Figure 1-7 , an alignment and pressing mechanism, which includes a base 1, a bottom plate 2, an alignment mechanism I and a pressing mechanism II, the base has two, and the bottom plate is installed on the two bases; the alignment mechanism includes a lifting motor 3. Lifting coupling 4. Lifting linear module 5. Lifting linear module slider 6. Lifting installation angle 7. Lifting installation strip 8. Lifting photoelectric sensor 9. Lifting sensor 10. CCD mounting plate 11. CCD fixing block 12. CCD13 and light source 14, the lifting motor is connected with the lifting linear module through the lifting coupling; the lifting linear module is connected with the lifting installation angle through the lifting linear module slider, and the lifting linear module The back is connected to the CCD mounting plate, and the two ends of the CCD mounting plate are vertically installed with CCD fixing blocks. The inner sides of the two CCD fixing blocks are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com