Intermittent rotary feeding device for lathe

A technology of feeding device and lathe, which is applied to automatic/semi-automatic lathes, turning equipment, manufacturing tools, etc., can solve the problem of low efficiency of manual operation of feeding device, and achieve the effects of simple structure, convenient disassembly and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

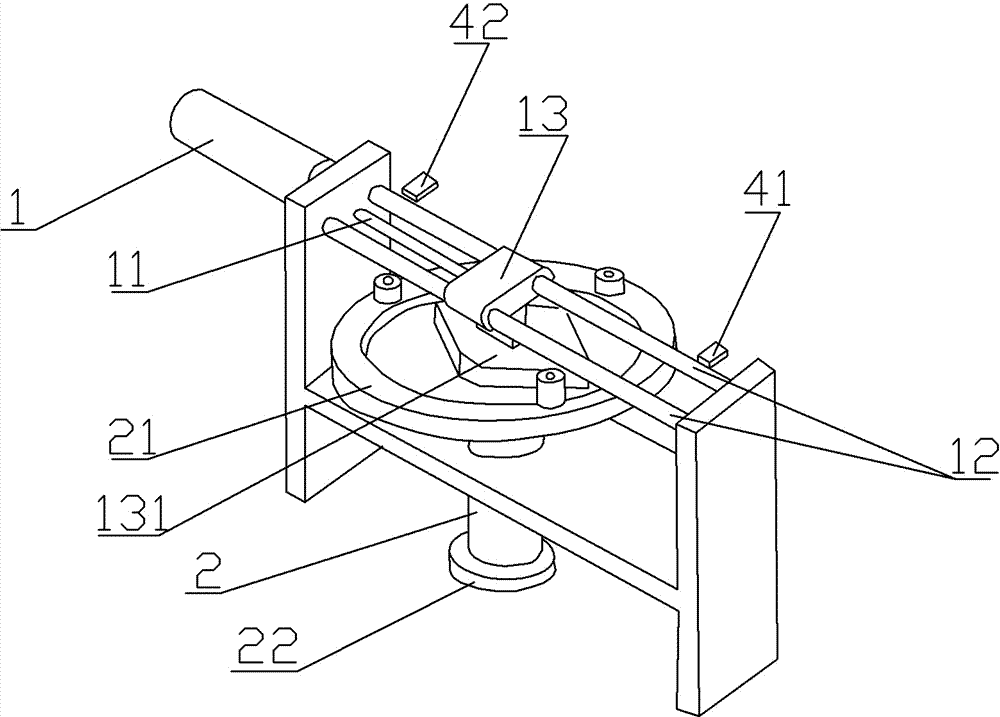

[0009] according to figure 1 As shown, the intermittent rotary feeding device for a lathe in this embodiment includes a frame, a hydraulic cylinder 1 mounted on the frame, and a push rod 11 driven by the hydraulic cylinder 1, and also includes a sliding block 13 connected with the push rod 11. The root end is fixed on the guide rod 12 on the frame, the rotating shaft 2 connected to the frame in rotation, the disc 21 connected to one end of the rotating shaft 2 and the feed clamp 22 screwed to the other end of the rotating shaft 2; There are three pins, and the sliding block 13 includes a guide block at the upper end that slides along the guide bar 12 and a diamond-shaped push block 131 at the lower end, and the push block 131 can be offset against the pins on the disc 21; 21 includes the left half and the right half, and the end faces of the left half and the right half are provided with inverted tapered protrusions and inverted tapered slots; the sliding block 13 on the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com