Intermittent feeding device used for lathe

A technology of feeding device and lathe, which is applied in the direction of automatic/semi-automatic lathes, turning equipment, automatic in/out of workpieces, etc., can solve the problems of low efficiency of manual operation of feeding devices, and achieve the effect of simple structure, convenient disassembly and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

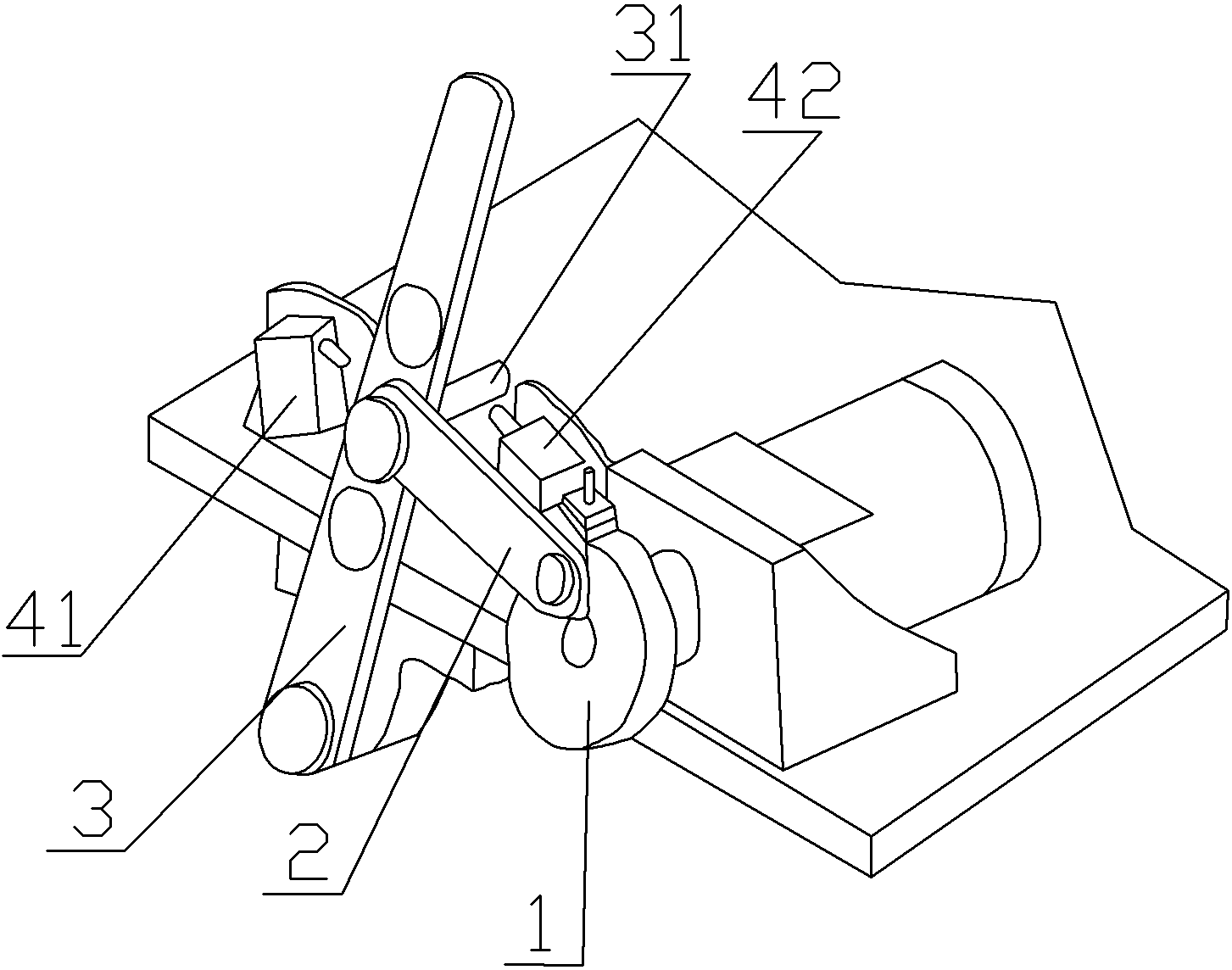

[0009] according to figure 1 As shown, the intermittent feeding device for a lathe in this embodiment includes a frame, a hydraulic cylinder 1 provided on the frame, and a push rod 11 driven by the hydraulic cylinder 1, and also includes a first leg 21 and a first leg connected to the push rod 11. Two supporting feet 22, a rotating shaft between the two supporting legs and connected to the frame, a disc 3 fixed on the rotating shaft and a feeding clamp connected to one end of the rotating shaft; the disc 3 is evenly distributed with three pins, so The first leg 21 is provided with a first drive block 211 at one end away from the push rod 11, and the second leg 22 is provided with a second drive block 221 at one end away from the push rod 11. The middle of the first drive block 211 is hinged with the first leg 21, and the second drive The middle of the block 221 is hinged to the second leg 22, wherein the first leg 21 is provided with a stop pin that restricts the first drive bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com