Lifting band end fixing device of setting machine

A technology of fixing device and lifting belt, which is applied in the direction of transportation, packaging, and object stacking, etc. It can solve the problems that the screws fixing the splint have no anti-loosening structure, the lifting belt is weakened, and high-strength anti-puncture cannot be used, so as to achieve firm fixation , Prevent loosening, increase the effect of fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

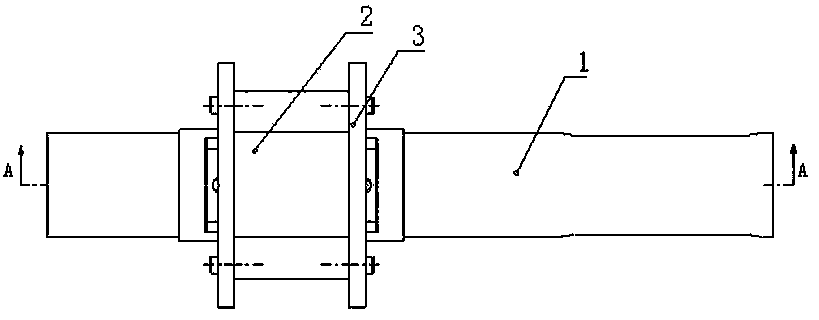

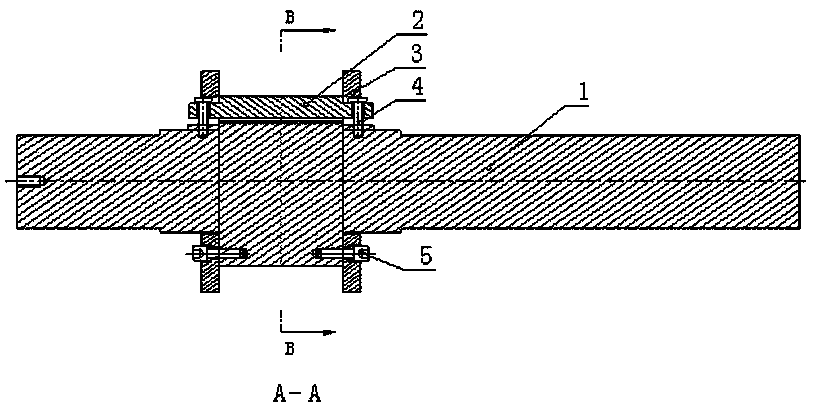

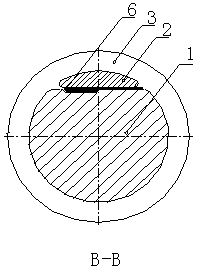

[0011] Such as figure 1 , 2 As shown in and 3, a fixing device for the end of the lifting belt of the code blank machine includes a roller shaft 1, a fan-shaped pressure plate 2 and a pressure plate screw 4, and the end of the lifting belt 6 is fixed on the roller shaft 1 through the fan-shaped pressure plate 2, and the roller shaft 1 is provided with a groove for placing the end of the lifting belt 6, and the fan-shaped pressure plate 2 seals the end of the lifting belt 6 in the groove, and the two ends of the fan-shaped pressure plate 2 are fixed on the roller shaft 1 by the pressure plate screw 4. Cut a plane on the side of the roller shaft 1, and then process a groove on this plane, so that the fan-shaped pressing plate 2 can seal the part of the lifting belt 6 end that has been folded and sewn in the groove, near the lifting belt 6 end. The rest of the part is clamped between this plane and the fan-shaped pressure plate 2, so as to realize the firm fixing of the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com