Noise monitoring system for carrier-rocket launch fuel-gas flows

A launch vehicle and noise monitoring technology, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of inability to systematically and finely evaluate the influence of the rocket body and launch system, limited measuring points, gas flow noise testing, Difficult to analyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

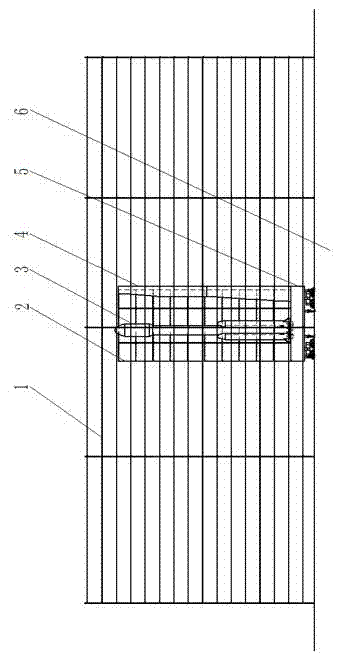

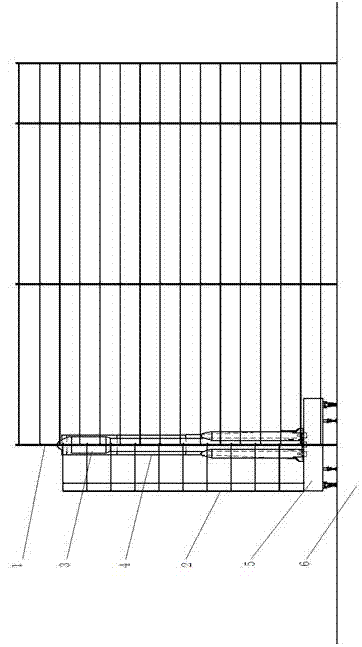

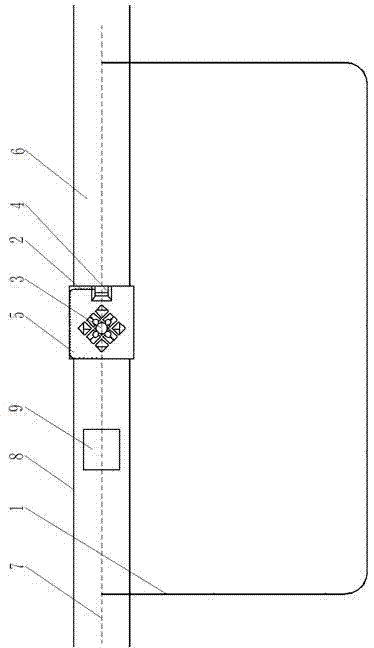

[0017] refer to Figure 1-Figure 8 , the launch vehicle launch system is located on site 6. The launch vehicle gas flow noise monitoring system is mainly constructed based on the launch system conditions, especially the structural scale of the launch system. Two sets of test array devices are used to realize the refined monitoring of the launch vehicle gas flow noise. One of the two sets of test array devices is a far-field test array device 1 , and the other is a near-field test array device 2 .

[0018] The far-field test array 1 is mainly used to test the dynamic distribution and change law of the noise source of the launch system during the entire launch process of the launch vehicle, especially the high-intensity sound source, and is suitable for monitoring the entire launch system, especially the launch platform 5, the launch site diversion groove and other position equipment, facility structures and openings (respectively in image 3 Shows the diversion tank outlet 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com