A rolling guide device

A guide device and guide roller technology, which is applied in the direction of guide/positioning/alignment devices, etc., can solve problems such as easy breakage and smaller diameter of guide rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

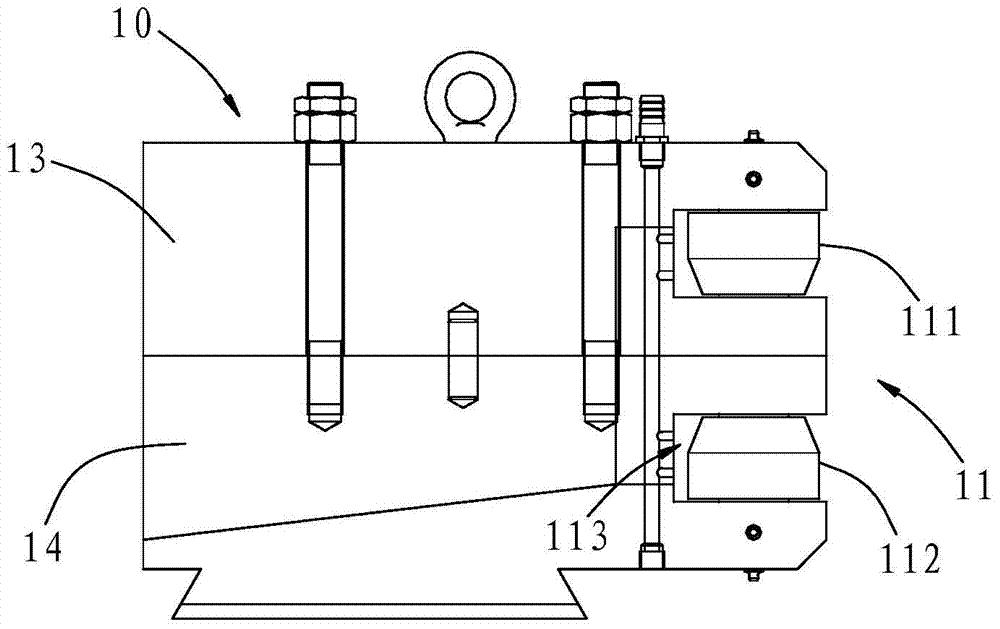

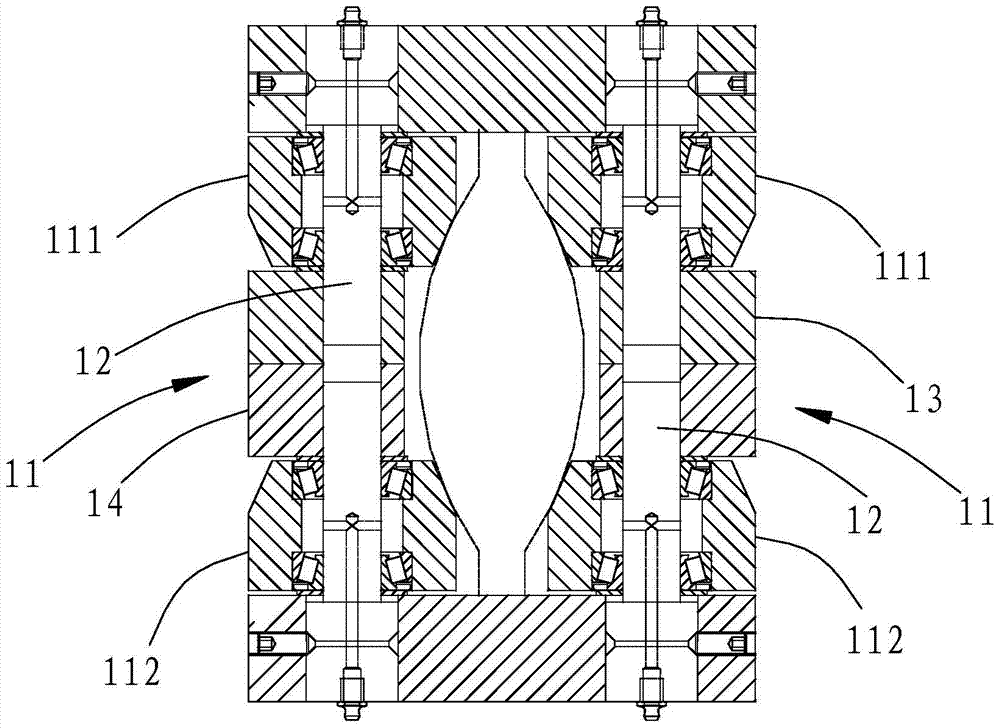

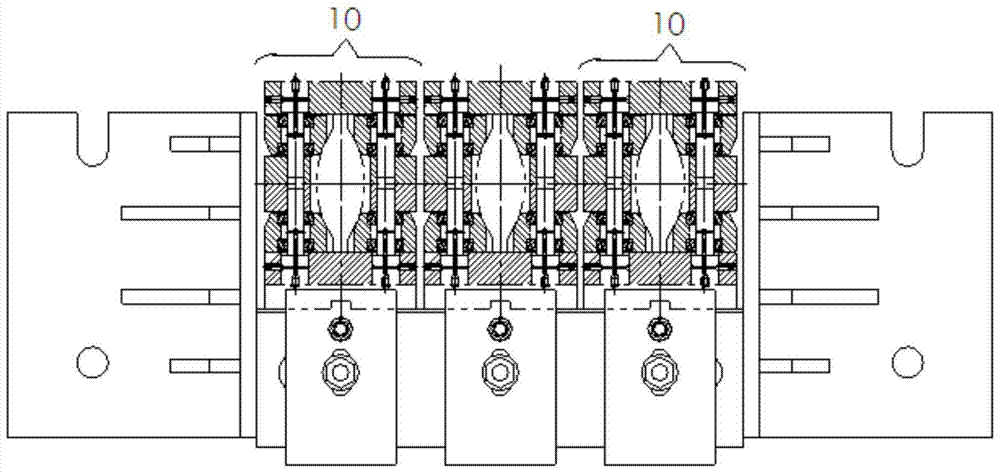

[0009] The purpose of the present invention is to solve the problem that the roll body is easy to break due to the reduction of the diameter of the roll body in multi-strand rolling. Its approach is to figure 1 , 2 As shown, a rolling guide device is characterized in that: it includes a guide box 10, and the guide box 10 is provided with a set of guide rollers for conveying the rolled piece. The first and second guide roller sets 11 fixed on the two rotating shafts 12 are respectively composed of upper and lower guide rollers 111 and 112 arranged up and down apart, and the upper and lower guide rollers 111 and 112 are in phase The adjacent ends are respectively arranged in a cone shape in which the outer diameter of the roll body gradually decreases from the middle to the end. In the present invention, the set of guide rollers can be arranged in the middle or at the end of the guide box 10 to meet the needs of different processes and operations. The rotating shaft 12 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com