Junction temperature monitoring circuit system for high-power LED reliability test

A technology for monitoring circuit and reliability, which is applied to thermometers, thermometers, and measuring devices that use directly heat-sensitive electrical/magnetic components, and can solve problems such as the inability to monitor junction temperature changes in real time, to meet diversity and improve flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

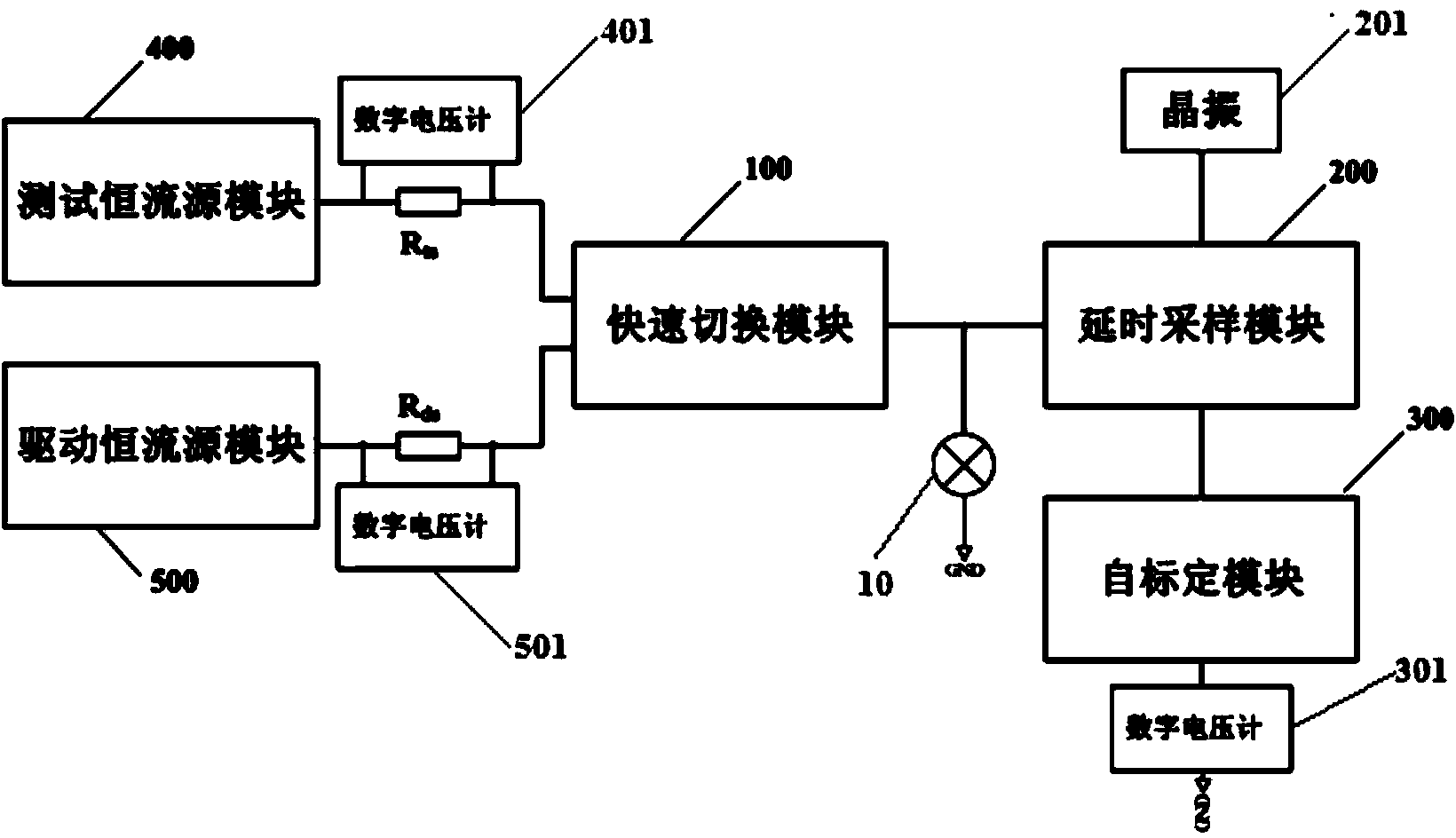

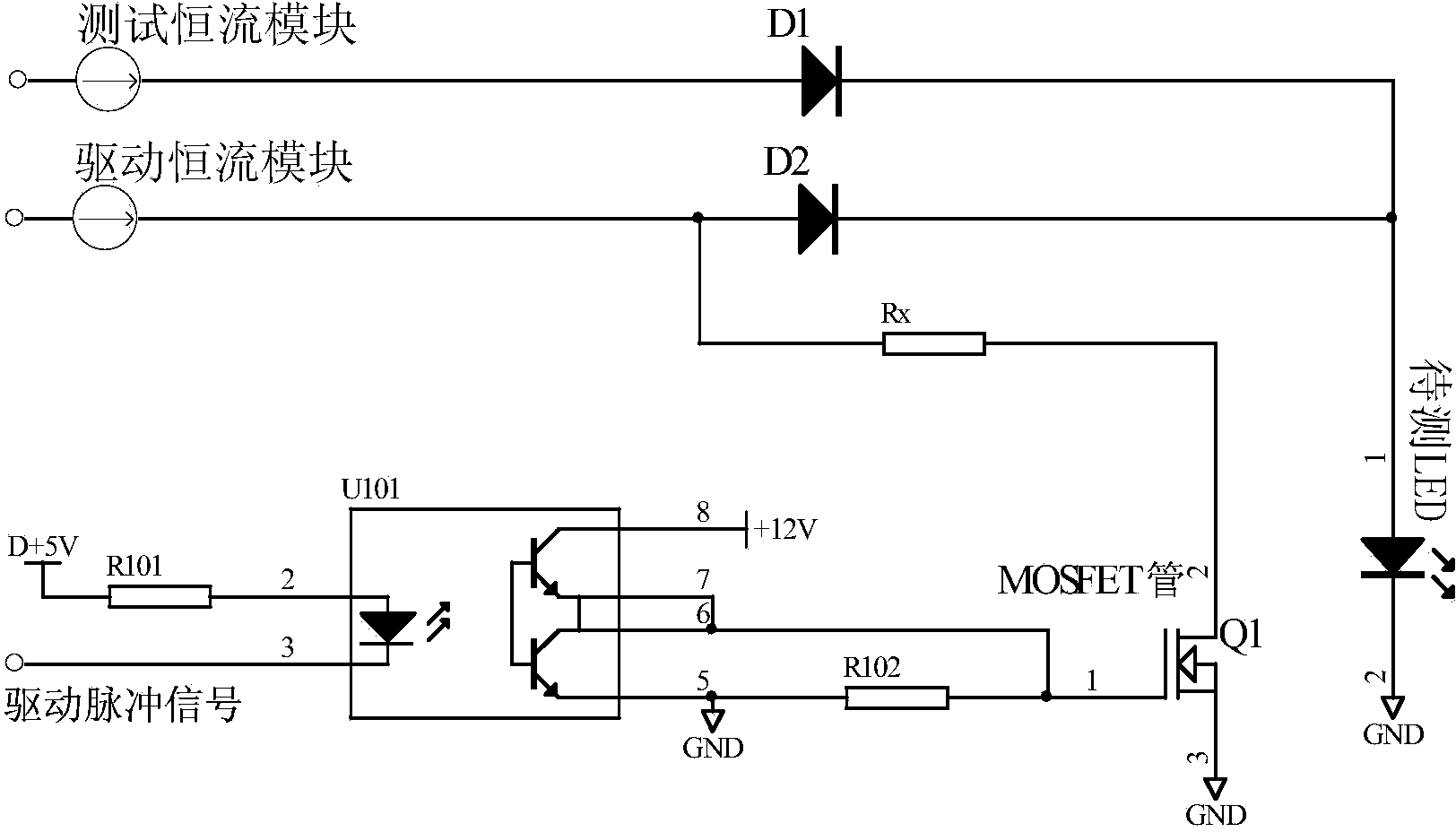

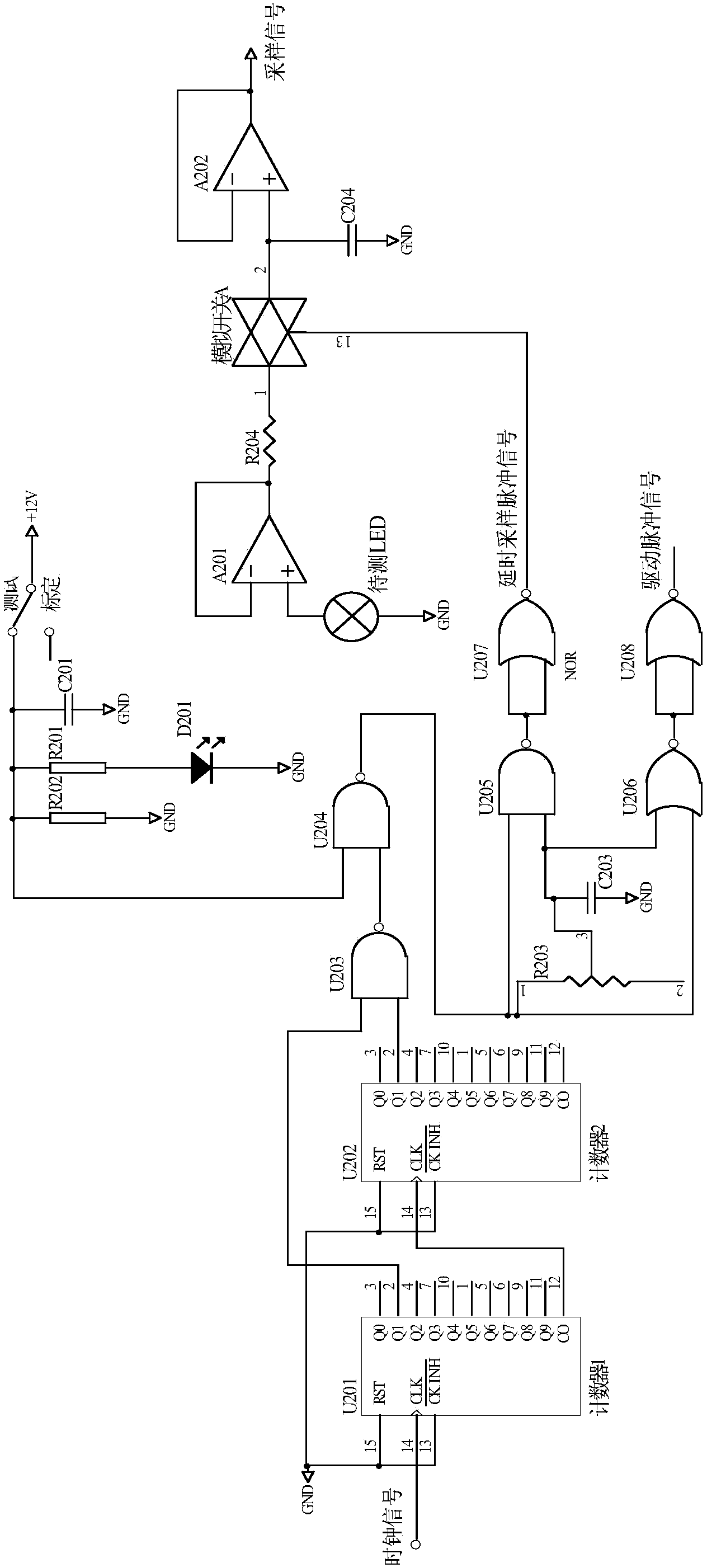

[0039] The specific structural principle block diagram of the monitoring circuit provided by the present invention is as figure 1 shown by figure 1 It can be seen that the monitoring circuit includes a fast switching module 100, a delay sampling module 200, a self-calibration module 300, a test constant current source module 400, and a driving constant current source module 500. The fast switching module will drive the constant current source module to cut off according to the sampling sequence. , the delay sampling module collects the forward voltage of the LED to be tested at the working time of the constant current source module, and the self-calibration module uses the inverse proportional amplification and zeroing circuit of the reference LED to obtain the voltage value corresponding to the current junction temperature, and the output The digital voltmeter conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com