R6H type magnetic core mould

A magnetic core mold and fixed mold technology, which is applied in the field of R6H magnetic core molds, can solve problems such as poor adjustability, uneven force, and low production efficiency, and achieve flexible adjustment of molding height, high molding efficiency, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

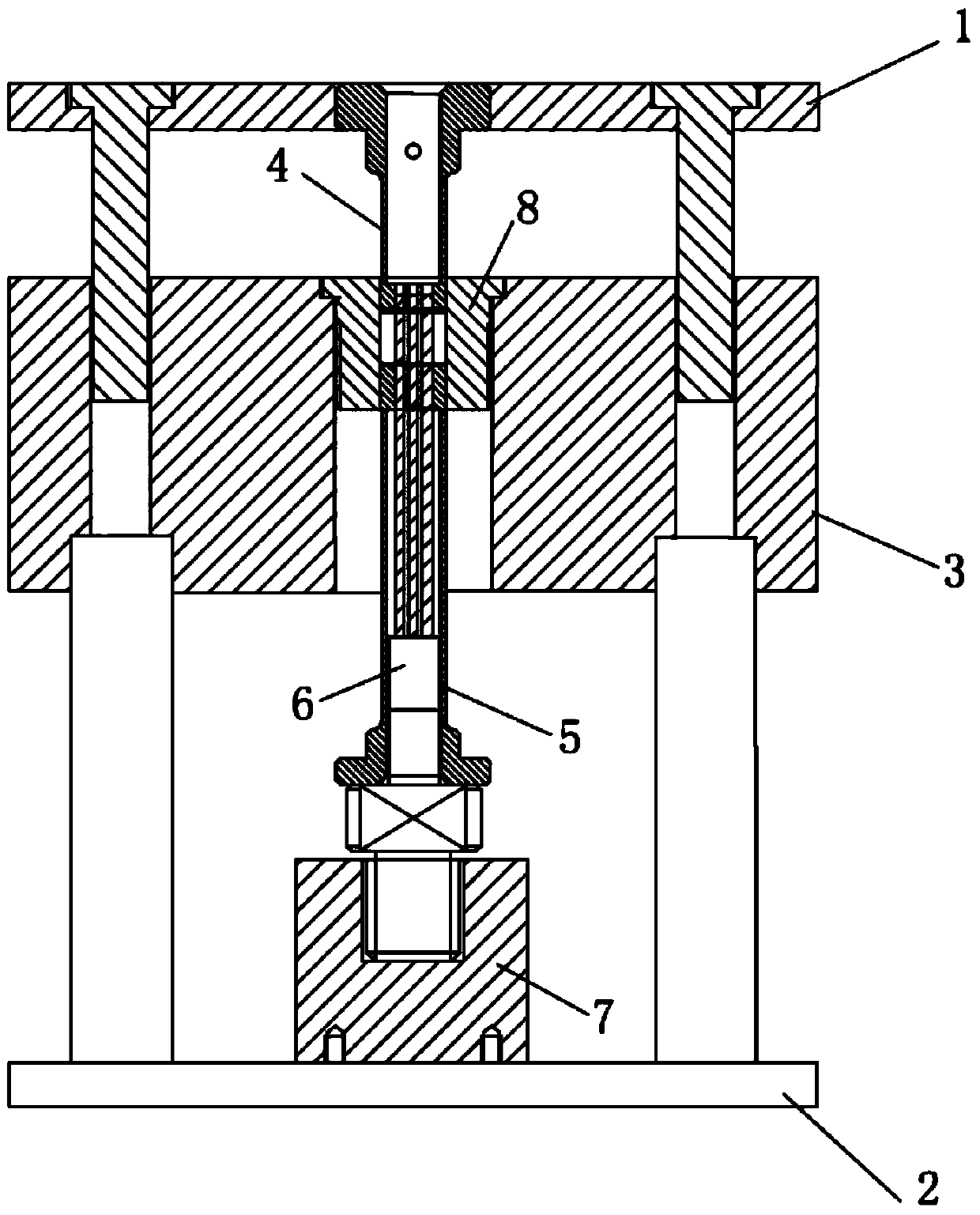

[0021] Attached below figure 1 To attach Figure 7 The technical solutions of the present invention are further described through specific implementation methods.

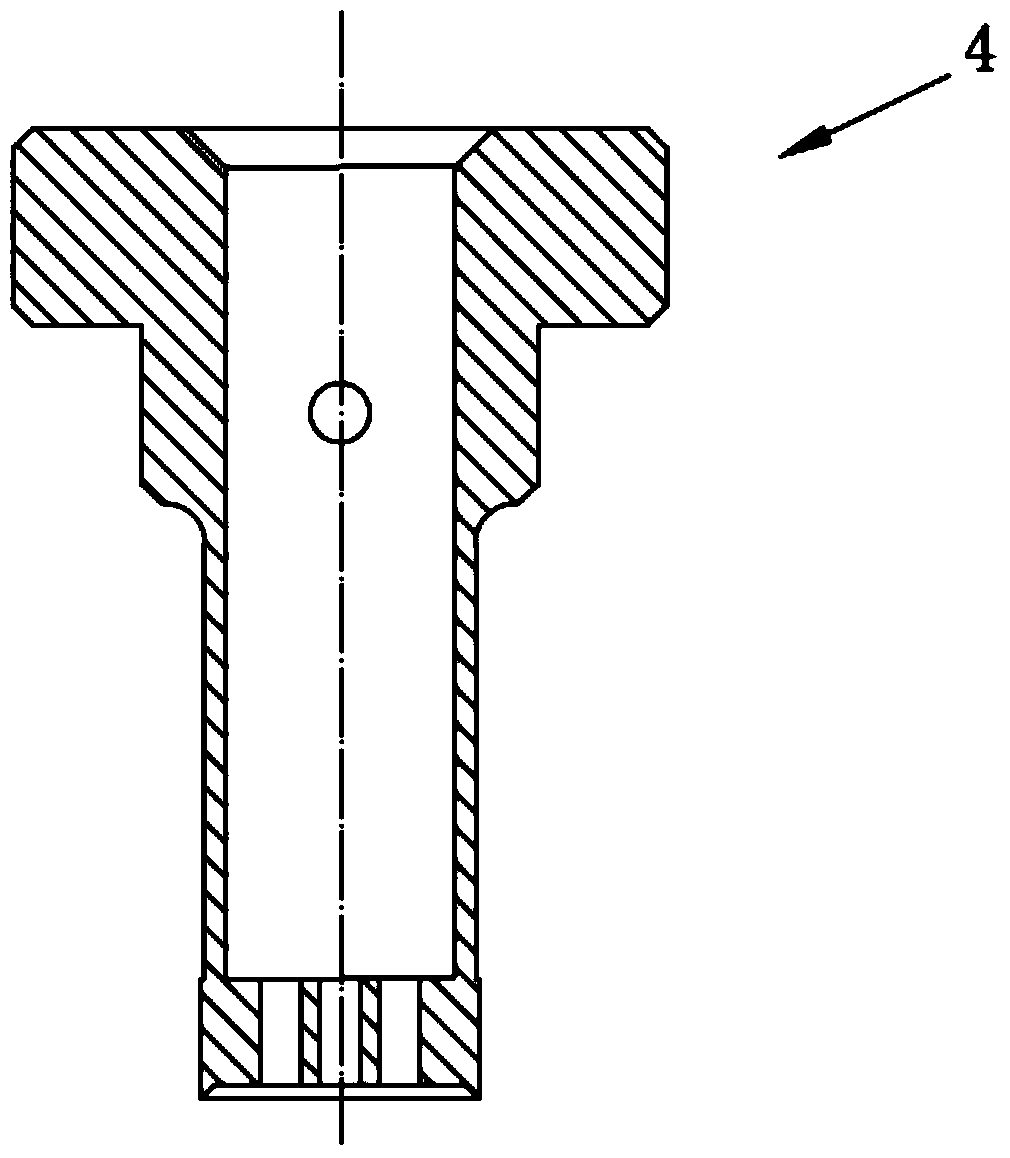

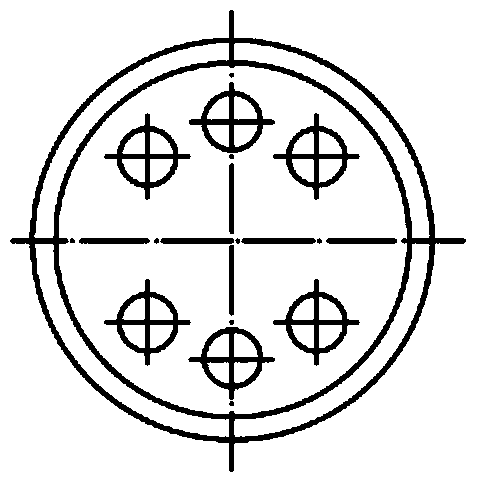

[0022] A kind of R6H type magnetic core mould, comprises movable mold bottom plate 1 and fixed mold bottom plate 2, and described fixed mold bottom plate 2 is provided with support column, and the top of described support column is provided with middle template 3 for fixing middle mold 8, so Both sides of the middle template 3 are provided with guide sleeves that match the guide posts on the movable mold bottom plate 1, and the middle part of the movable mold bottom plate 1 is fastened with a hole that matches one end of the cavity of the middle mold 8. The upper punch 4, the other end of the cavity is provided with a lower punch 5 matching the cavity, and the cavity of the lower punch 5 is provided with 6 punches at one end of the cavity. The middle rod 6 matched with the first column hole, the middle rod 6 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap