A method and product for preparing ultra-thin porous Wo3 gas-sensitive coating by thermal spraying technology

A thermal spraying, ultra-thin technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problem of less involved in the preparation of gas-sensitive coating, achieve easy industrialized large-scale production, low production cost , to avoid the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

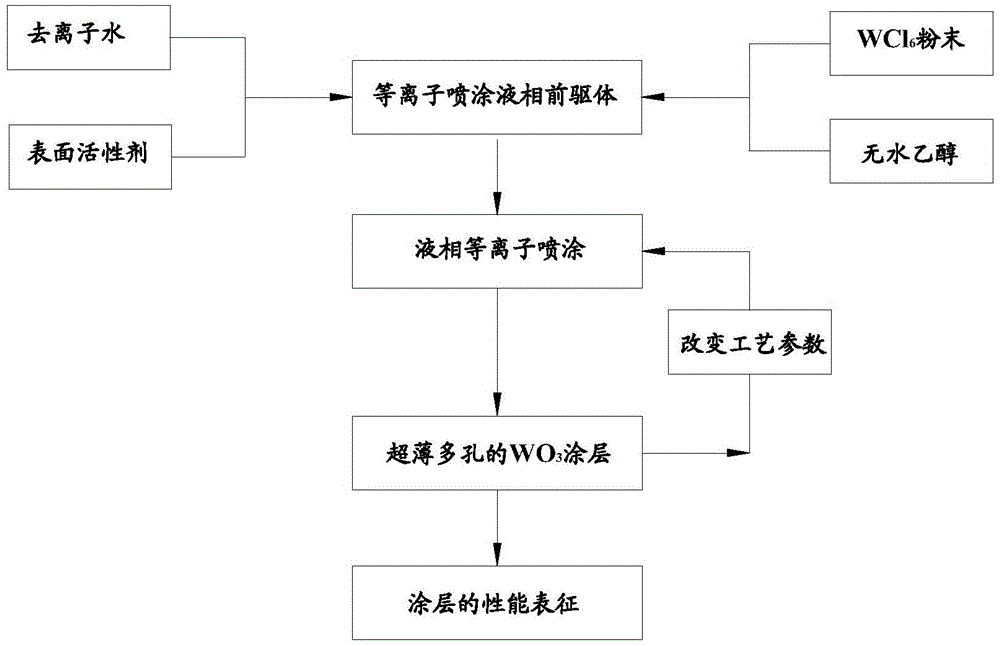

Method used

Image

Examples

Embodiment 1

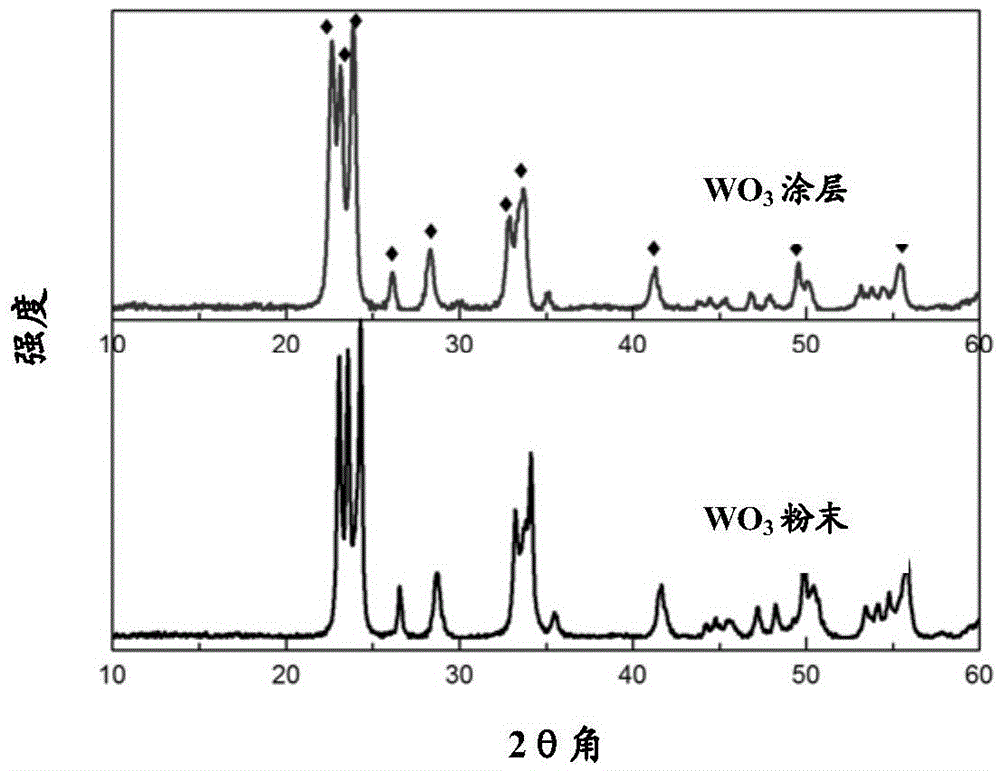

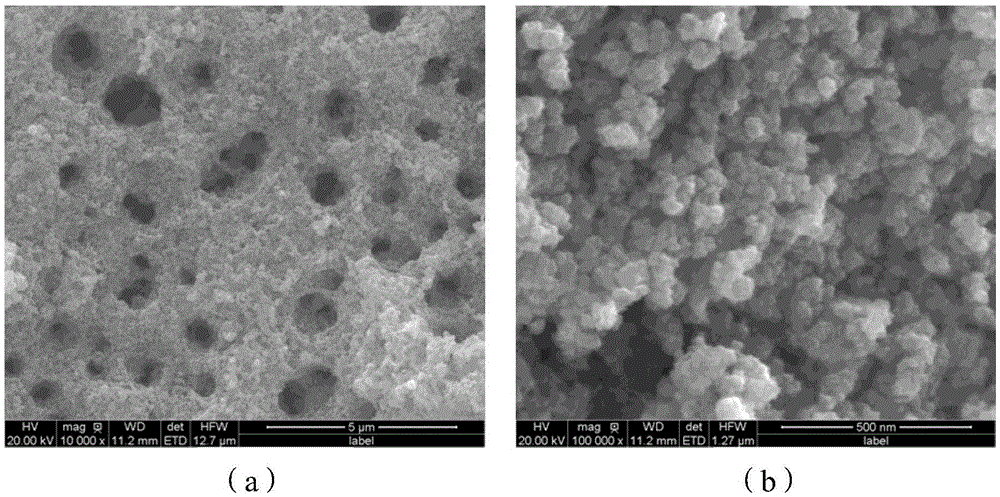

[0041] In this embodiment, the substrate material is a 304 stainless steel sheet with a thickness of about 2mm, and the substrate surface WO 3 The thickness of the coating is 500nm, and the coating is well combined with the matrix material; the surface of the coating is ultra-thin porous nano-sized WO 3 Grain stacked, WO 3 The grain size ranges from 30 to 100nm. The porous submicron size WO 3 The specific preparation method of the coating is as follows:

[0042] 1. The commercially available WCl 6 Add it into absolute ethanol and stir evenly, ultrasonically disperse for 20min, add 0.08wt% surfactant polyethylene glycol 600 into deionized water, stir evenly, wherein the volume ratio of deionized water and absolute ethanol is 1:1, Then add it to WCl 6 in anhydrous ethanol solution, and ultrasonically dispersed for 20 minutes to obtain WCl 6 A solution with a solid content of 4%, and then adjust the pH of the above solution to 7 with ammonia water under the condition of mag...

Embodiment 2

[0050] In this embodiment, the base material is Al with a thickness of about 1mm 2 o 3 sheet, the substrate surface WO 3 The thickness of the coating is 600nm, and the coating is well combined with the base material; the surface of the coating is ultra-thin porous submicron size WO 3 Grain stacked, WO 3 The grain size ranges from 50 to 150nm. The ultrathin porous submicron size WO 3 The specific preparation method of the coating is as follows:

[0051] 1. The commercially available WCl 6 Add it into absolute ethanol and stir evenly, ultrasonically disperse for 30min, add 0.08wt% surfactant polyethylene glycol 20000 into deionized water, stir evenly, wherein the volume ratio of deionized water and absolute ethanol is 1:2, Then add it to WCl 6 in anhydrous ethanol solution, and ultrasonically dispersed for 30 minutes to obtain WCl 6 A solution with a solid content of 5%, and then adjust the pH of the above solution to 8 with ammonia water under the condition of magnetic ...

Embodiment 3

[0059] In this embodiment, the base material is a slide glass with a thickness of about 1mm, and the surface of the base body is WO 3 The thickness of the coating is 500nm, and the coating is well combined with the matrix material; the surface of the coating is ultra-thin porous nano-sized WO 3 Grain stacked, WO 3 The grain size ranges from 20 to 100nm. The loose porous WO 3 The specific preparation method of the coating is as follows:

[0060] 1. The commercially available WCl 6 Add it into absolute ethanol and stir evenly, ultrasonically disperse for 40min, add 0.08wt% surfactant cetyltrimethylammonium bromide into deionized water, stir evenly, wherein deionized water and absolute ethanol Ratio 1:1, then add it to WCl 6 in anhydrous ethanol solution, and ultrasonically dispersed for 40min to obtain WCl 6 A solution with a solid content of 7%, and then adjust the pH of the above solution to 7 with ammonia water under the condition of magnetic stirring to obtain ultra-th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com