A kind of micro-nano structured photocatalytic coating and preparation method thereof

A technology of micro-nano structure and photocatalysis, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of poor photocatalytic performance of coatings, high requirements for raw materials and equipment, and low deposition rate, etc. problem, achieve the effect of reducing TiO2 agglomeration, low cost and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

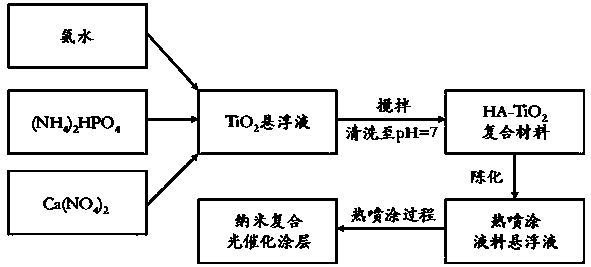

Method used

Image

Examples

Embodiment 1

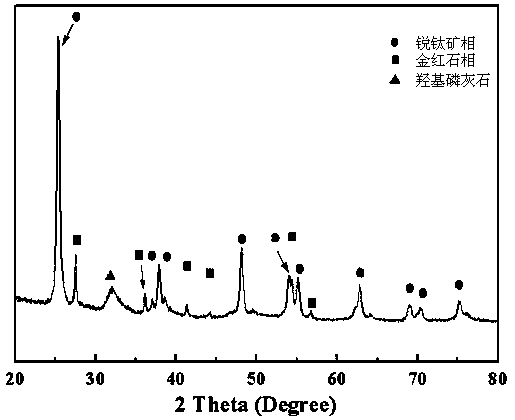

[0039] In the present embodiment, the selected substrate is a 316L stainless steel sheet with a thickness of about 2mm, and the nanometer HA-TiO 2 The thickness of the photocatalytic composite is about 50 μm, and the mass percentage of nano-HA in the coating is 30wt%. The coating is a porous micro-nano structure, mainly including nano-HA-TiO 2 The particles are piled up, and the nano-HA is spherical, and the TiO in the coating 2 The crystal forms are anatase phase and rutile phase, and the anatase phase has no obvious transformation, and the coating is well combined with the substrate. The concrete preparation method of this coating is as follows:

[0040] (1) The concentration of calcium nitrate solution is configured to be 2.5mol / L, and the concentration of ammonium dihydrogen phosphate solution is 1.5mol / L;

[0041] (2) After curing the hydroxyapatite precursor slurry for 5 hours, add commercially available P25 with an average particle size of 25nm, in which TiO 2 The ma...

Embodiment 2

[0053] In the present embodiment, the selected substrate is a 316L stainless steel sheet with a thickness of about 2mm, and the nanometer HA-TiO 2 The thickness of the photocatalytic composite is about 100μm, and the mass percentage of nano-HA in the coating is 40wt%. The coating is a porous micro-nano structure, mainly including nano-HA-TiO 2 The particles are piled up, and the nano-HA is needle-shaped, and the TiO in the coating 2 The crystal forms are anatase phase and rutile phase, and the anatase phase has no obvious transformation, and the coating is well combined with the substrate. The concrete preparation method of this coating is as follows:

[0054] (1) The concentration of calcium nitrate solution is configured to be 2.5mol / L, and the concentration of ammonium dihydrogen phosphate solution is 1.5mol / L;

[0055] (2) After curing the hydroxyapatite precursor slurry for 1.5 hours, add commercially available P25 with an average particle size of 25nm, in which TiO 2 ...

Embodiment 3

[0067] In this embodiment, the selected substrate is a 304 stainless steel sheet with a thickness of about 2mm, and the nanometer HA-TiO 2 The thickness of the photocatalytic composite is about 80 μm, and the mass percentage of nano-HA in the coating is 35wt%. The coating is a porous micro-nano structure, mainly including nano-HA-TiO 2 The particles are piled up, and the nano-HA is spherical, and the TiO in the coating 2 The crystal forms are anatase phase and rutile phase, and the anatase phase has no obvious transformation, and the coating is well combined with the substrate. The concrete preparation method of this coating is as follows:

[0068] (1) The concentration of calcium nitrate solution is configured to be 2.5mol / L, and the concentration of ammonium dihydrogen phosphate solution is 1.5mol / L;

[0069] (2) After curing the hydroxyapatite precursor slurry for 4 hours, add commercially available P25 with an average particle size of 25nm, in which TiO 2 The mass perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com