Nanometer TiO2 photocatalysis self-cleaning coating suitable for background colors of building walls and preparation method thereof

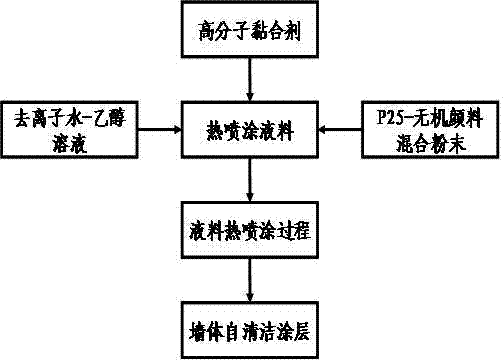

A technology for self-cleaning coatings and building walls, applied in coatings, metal material coating processes, fusion spraying, etc., can solve problems such as difficult matching, limited use range, single color, etc., and achieve good combination and high ratio Surface area, reducing the effect of the spray granulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

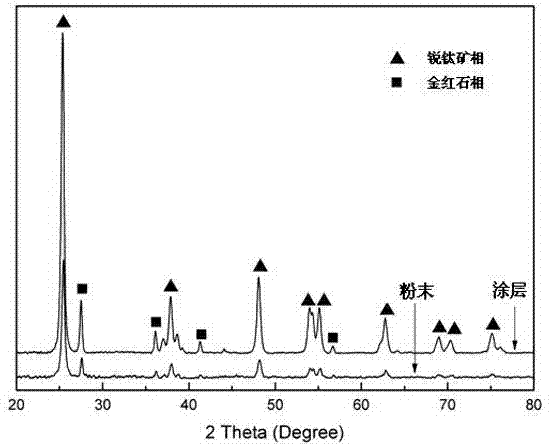

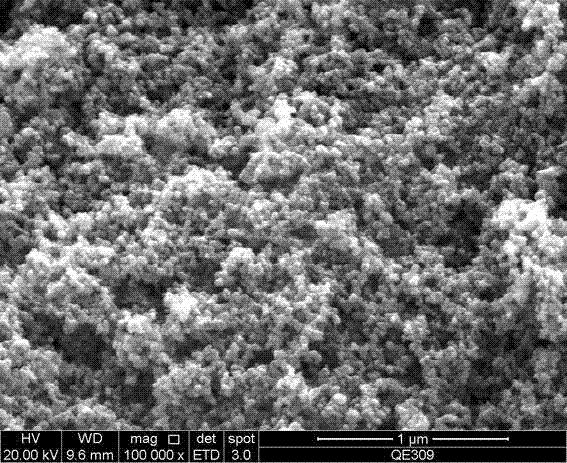

[0034] In this embodiment, the substrate material is a 316L stainless steel sheet with a thickness of about 2 mm, and the nano-TiO on the surface of the substrate 2 The thickness of the coating is 40 μm, and the TiO 2 The crystal phase components are anatase phase and rutile phase. According to the mass fraction, the anatase type accounts for 80%. The coating is well combined with the substrate, and the coating surface has a porous micro-nano structure. The concrete preparation method of this coating is as follows:

[0035] 1. Mix deionized water and absolute ethanol at a volume ratio of 4:1 to make a solution, add commercially available P25 nano-powder with an average particle size of 20 nm to the above prepared solution at 3 wt%, and stir magnetically to mix evenly. Add water-based polyurethane solution PU, polyvinylpyrrolidone PVP and gray color modifier to the above-mentioned mixed solution at 0.7 wt%, 0.13 wt% and 0.3 wt%, respectively, and magnetically stir to mix evenl...

Embodiment 2

[0043] In the present embodiment, the substrate material is a 316L stainless steel sheet with a thickness of about 2mm, and the nano-TiO2 coating on the surface of the substrate has a thickness of 50 μm, and in this coating, the TiO 2 The crystal phase components are anatase phase and rutile phase. According to the mass fraction, the anatase type accounts for 80%. The coating is well combined with the substrate, and the coating surface has a porous micro-nano structure. The concrete preparation method of this coating is as follows:

[0044] 1. Mix deionized water and absolute ethanol at a volume ratio of 1:1 to form a solution, add commercially available P25 nano-powder with an average particle size of 20nm at 5 wt% to the above prepared solution, and magnetically stir to mix evenly. Water-based polyurethane solution PU, polyvinylpyrrolidone PVP and gray color modifier are added to the above-mentioned mixed solution at 0.6 wt%, 0.2 wt% and 0.5 wt%, respectively, and magnetical...

Embodiment 3

[0052] In the present embodiment, the substrate material is a 316L stainless steel sheet with a thickness of about 2 mm, and the nano-TiO on the surface of the substrate 2 The thickness of the coating is 20 μm, and the TiO in the coating 2 The crystal phase components are anatase phase and rutile phase. According to the mass fraction, the anatase type accounts for 80%. The coating is well combined with the substrate, and the coating surface has a porous micro-nano structure. The TiO 2 The specific preparation method of the coating is as follows:

[0053] 1. Mix deionized water and absolute ethanol at a volume ratio of 1:1 to make a solution, add commercially available P25 nano-powder with an average particle size of 20nm at 5wt% into the above prepared solution, stir and mix evenly, and mix the water-based Polyurethane solution PU and orange color modifier are added to the above-mentioned mixed solution at 1.2wt% and 0.4wt% respectively, and magnetically stirred to mix evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com