Display device turn-over type structure

A flip-up display technology, applied in the field of aviation machinery, can solve problems such as limited space inside the chassis, difficulty in maintaining the overall strength and rigidity of the chassis structure, and inconvenient maintenance of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

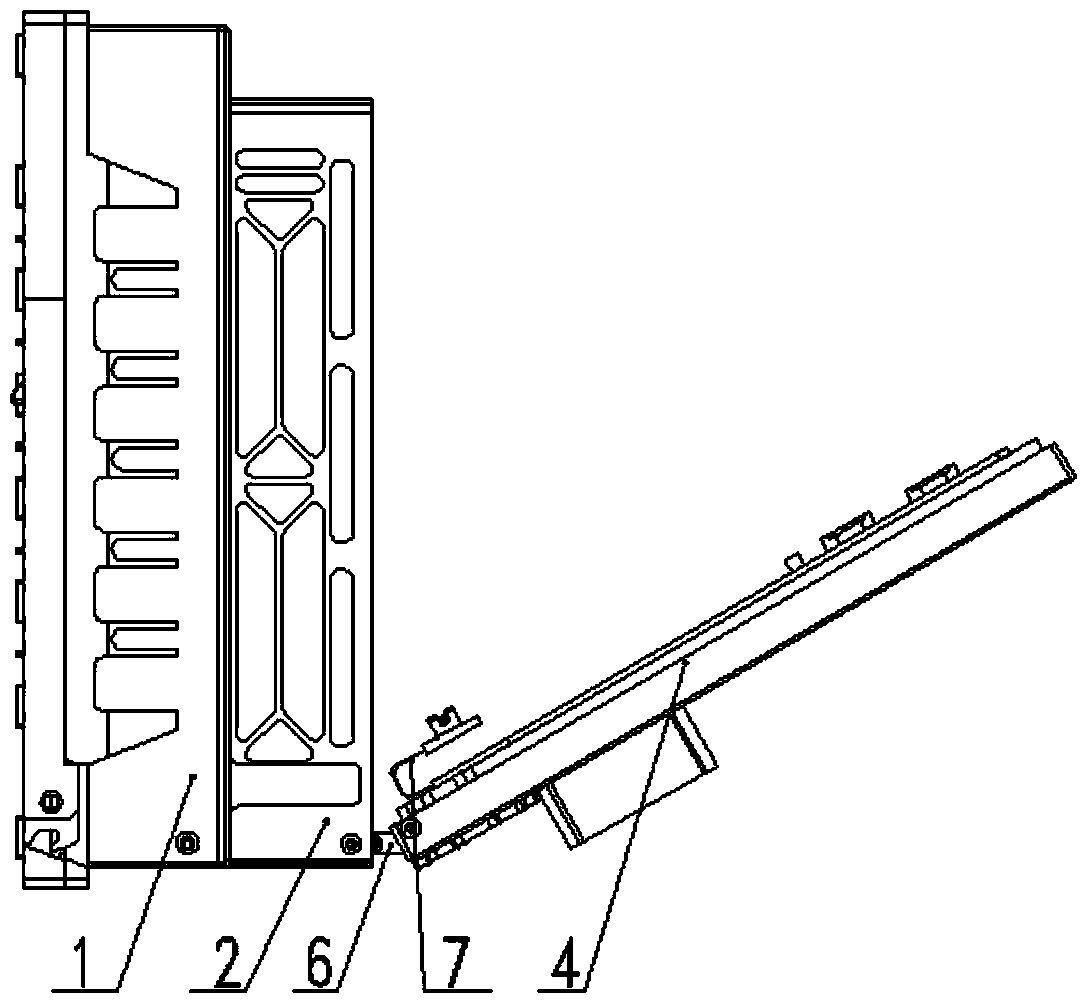

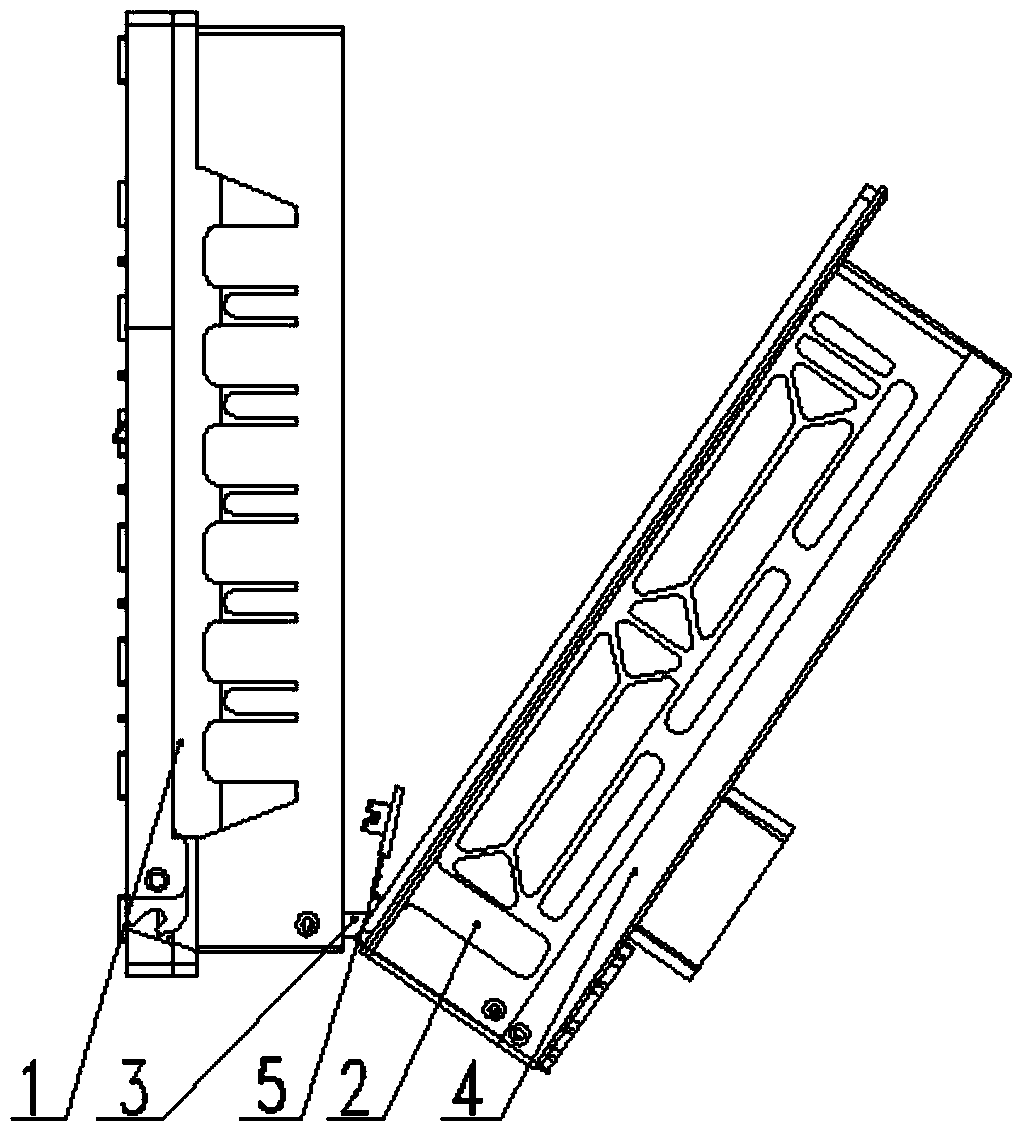

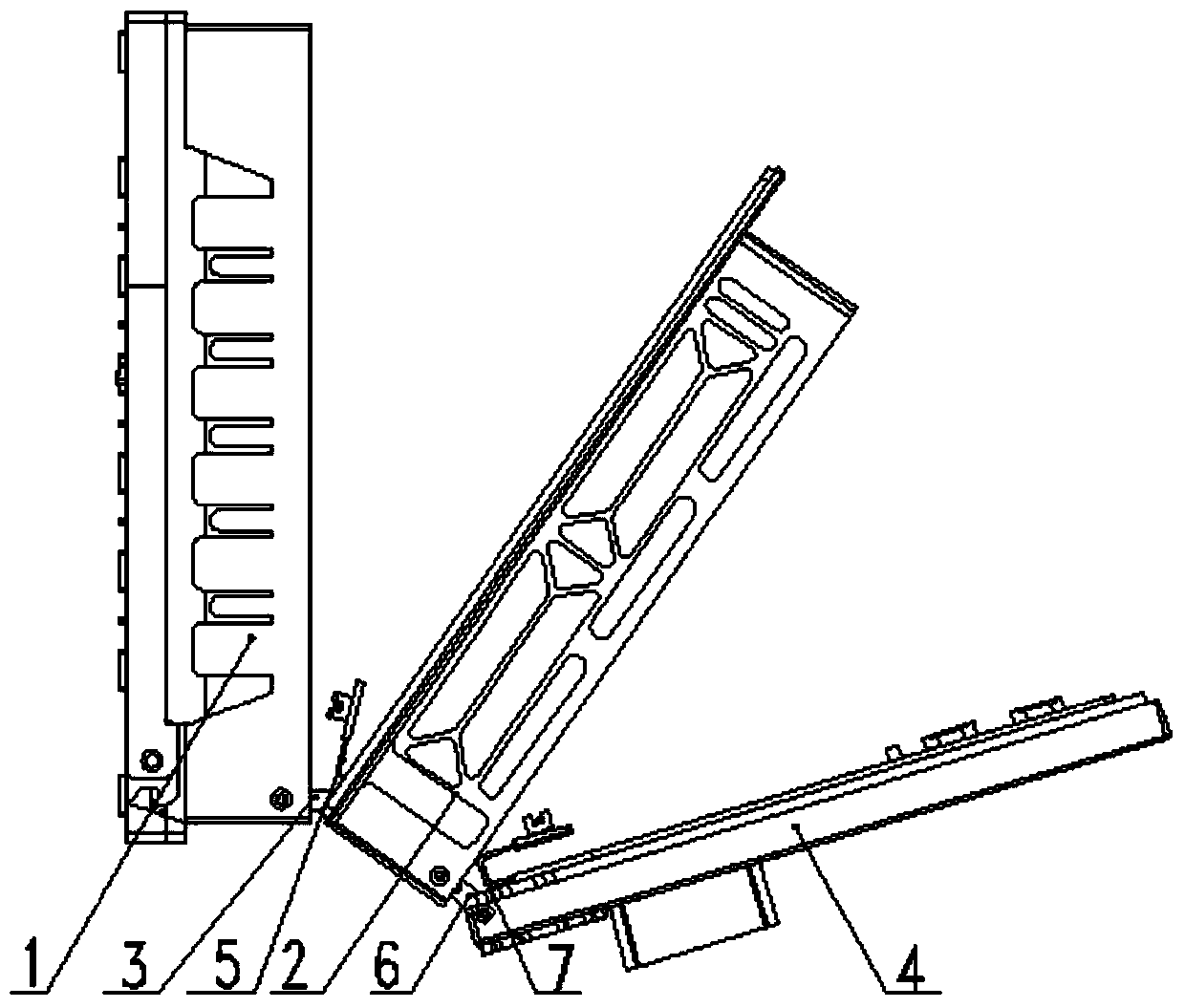

[0019] like Figures 1 to 4 As shown, a new type of display unit structure, by dividing the display into units, the front frame unit, middle frame unit and rear cover unit of this structure are electrically connected through a flexible circuit board, and are connected through a rotating arm unit. Structural connections.

[0020] The flip-up display structure includes a front frame unit 1, a middle frame unit 2, a first rotating arm unit 3, a rear cover unit 4, a first flexible circuit board 5, a second rotating arm unit 6 and a second flexible circuit board 7, Wherein, the front frame unit 1 is structurally connected with the middle frame unit 2 through the first rotating arm unit 3 and fixing screws, the front frame unit 1 is electrically connected with the middle frame unit 2 through the first flexible circuit board 5, and the middle frame unit 2 is structurally The upper part is connected with the rear cover unit 4 through the second rotating arm unit 6 and fixing screws, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com