Horizontal dirt separator for water system

A horizontal decontamination device and decontamination device technology, applied in the direction of chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of complex structure, poor decontamination effect, and difficult maintenance of the decontamination device, so as to reduce welding The amount of work, the convenience of sewage and cleaning, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

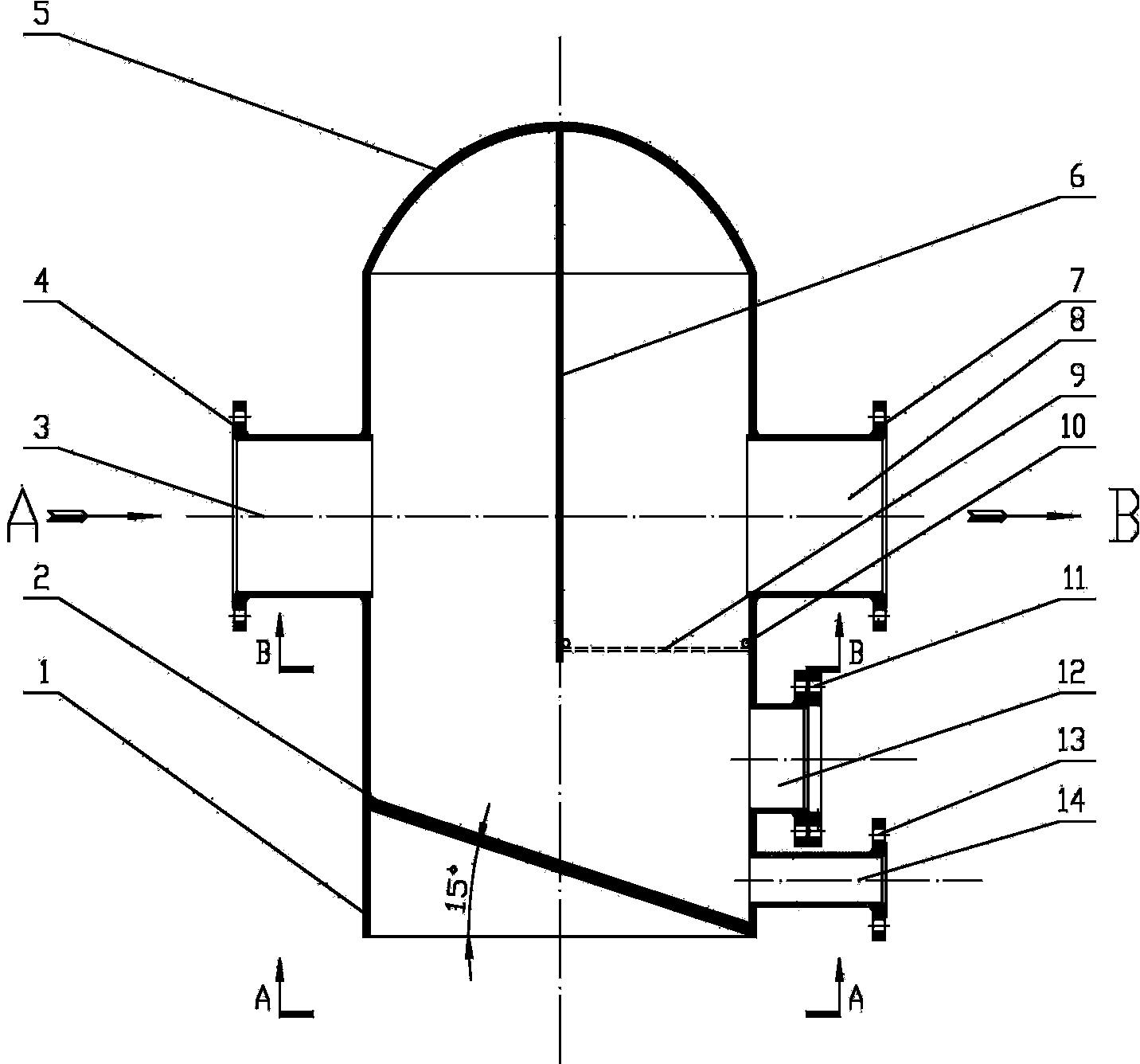

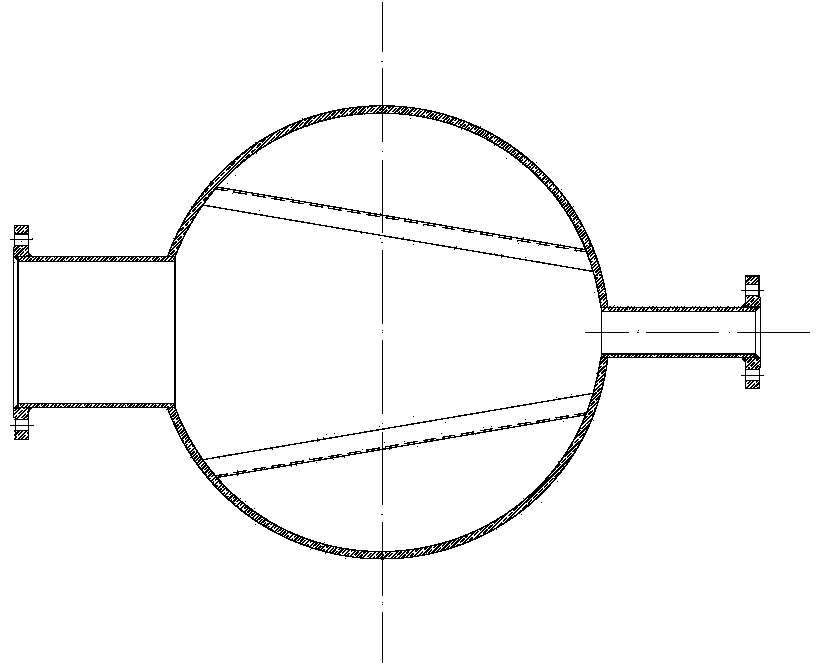

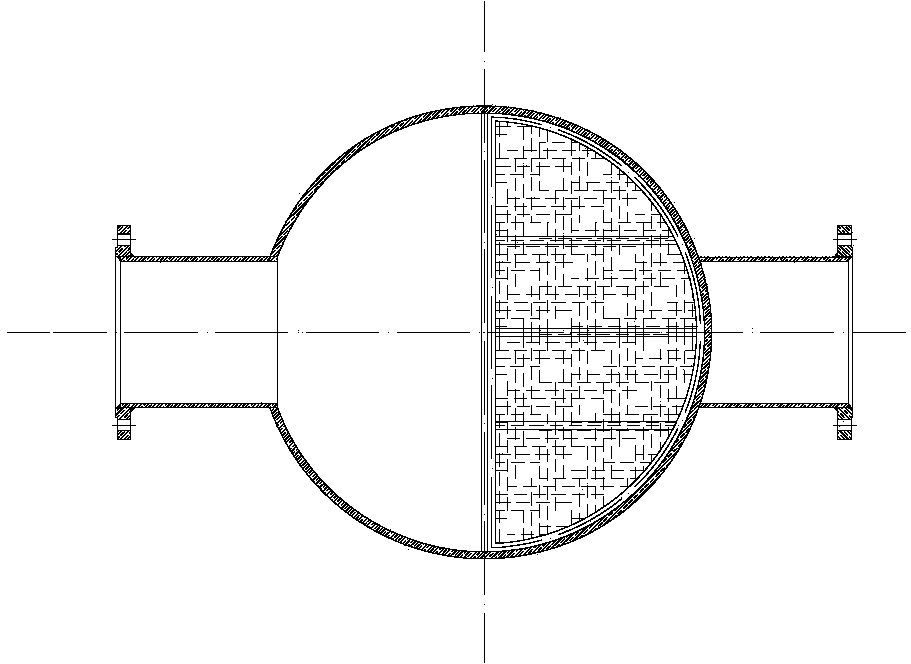

[0013] Structure of the present invention sees figure 1 . The horizontal decontamination device for the water system is installed horizontally in the horizontal direction of the decontamination device cylinder body 1, water enters from the water inlet 3 on one side, and flows out from the water outlet 8 on the other side. In the upper part of the middle position inside the decontamination device cylinder 1, a water baffle 6 is vertically arranged. The water baffle 6 is separated between the water inlet 3 and the water outlet 8, so that the running water is turned at the water baffle 6, and after passing through the water flow channel between its lower edge and the bottom of the decontamination device cylinder 1, it is folded again. Turn and flow out from water outlet 8. The water baffle plate 6 inside the decontamination device cylinder 1 is located in the channel on the side of the water outlet 8, and a filter screen 9 is horizontally arranged. The bottom plate 2 of the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com