Multi-axis linkage device capable of realizing five-surface machining

A multi-axis linkage and surface processing technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of the difficulty in the configuration of the full parallel five-degree-of-freedom parallel mechanism, and achieve the effect of large rotation output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

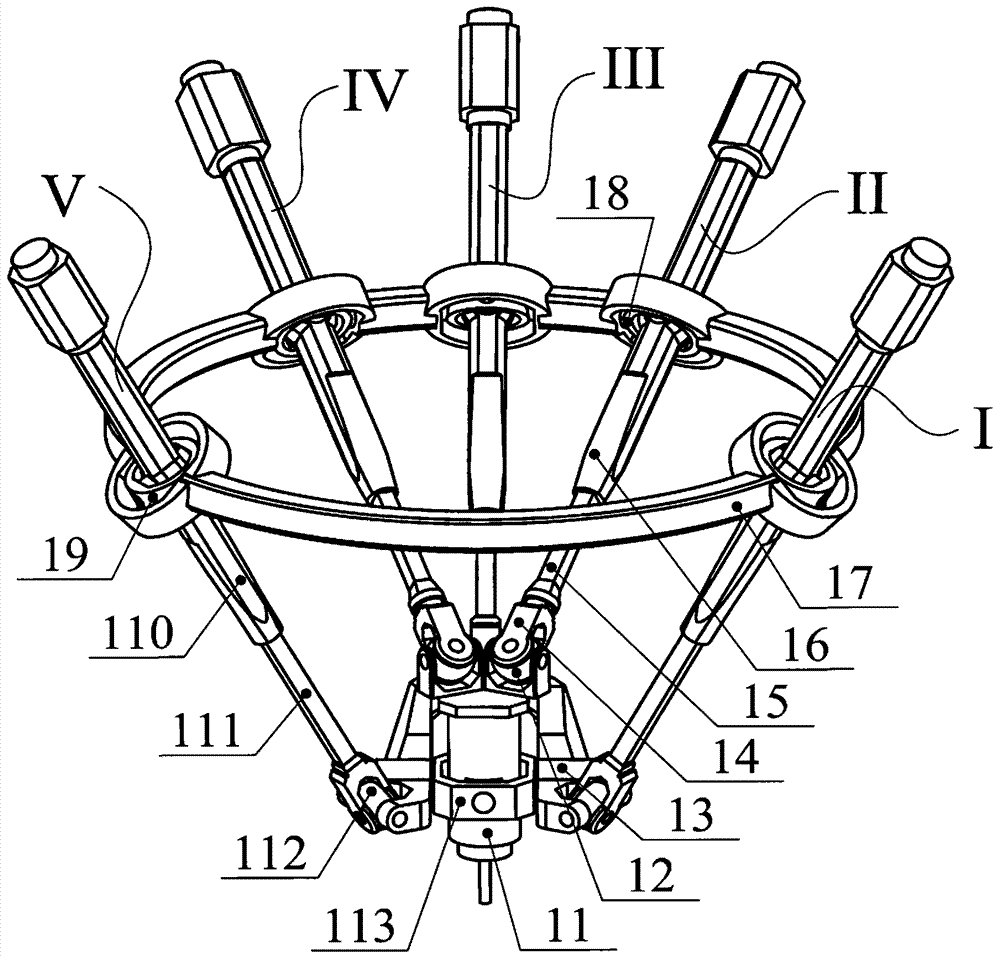

[0020] The structure of a multi-axis linkage device that can realize five-face machining in this embodiment is as follows: figure 1 As shown, it includes a fixed platform 17, a moving platform 11, a U-shaped frame 13 and a support frame 113, and the first, third and fifth branch chains between the fixed platform 17 and the U-shaped frame 13 are connected. The second and fourth branch chains between the moving platform 11 and the fixed platform 17; the first, the third and the fifth branch chains are respectively connected with the fixed platform 17 and the U-shaped frame 13, and the U-shaped frame 13 is connected with the rotating pair The supporting frame 113 is connected, and the supporting frame 113 is connected with the moving platform 11 through a rotating pair, and the second and fourth branch chains are respectively connected with the fixed platform 17 and the moving platform 11, thereby forming a space parallel closed-loop mechanism.

[0021] The first, third and fifth...

Embodiment 2

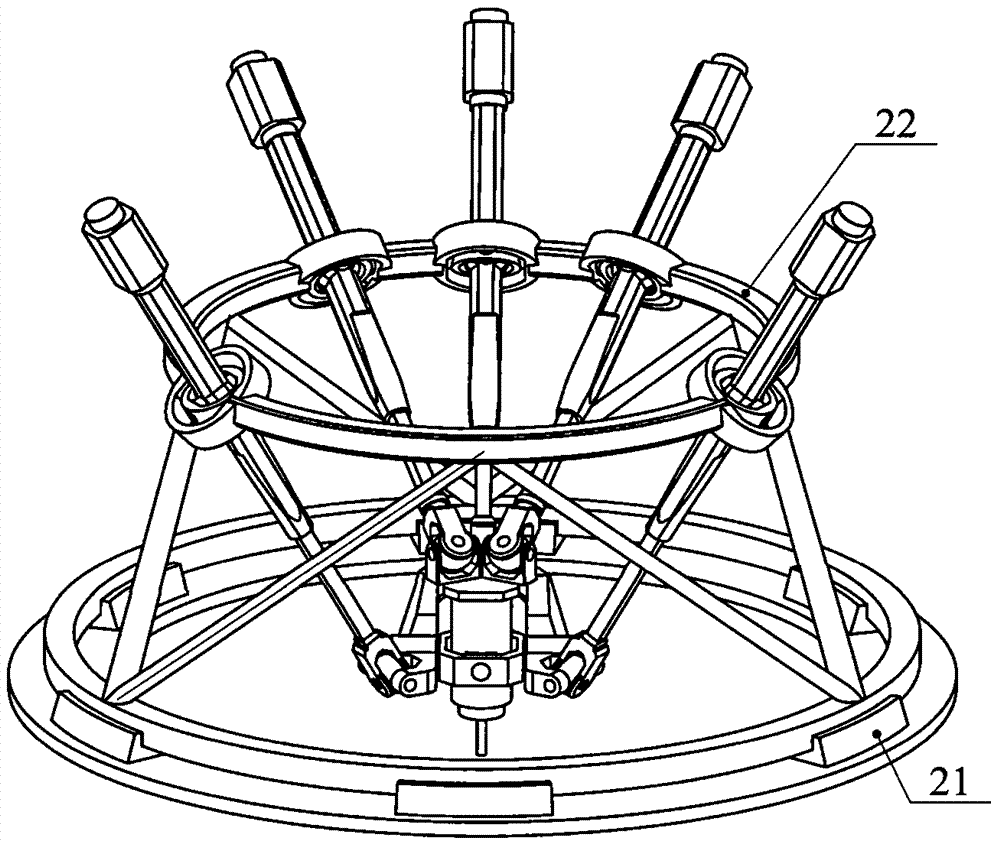

[0025] The structure of a multi-axis linkage device that can realize five-face machining in this embodiment is as follows: figure 2As shown, the multi-axis linkage device is different from Embodiment 1 in that: the multi-axis linkage device also includes a circular guide rail 21 and a kinematic pair. There is one kinematic pair, which is a rotary pair connected between the fixed platform 22 and the annular guide rail 21, and the rotary pair is driven. The device can realize six-axis linkage control of three moving degrees of freedom and three rotating degrees of freedom.

Embodiment 3

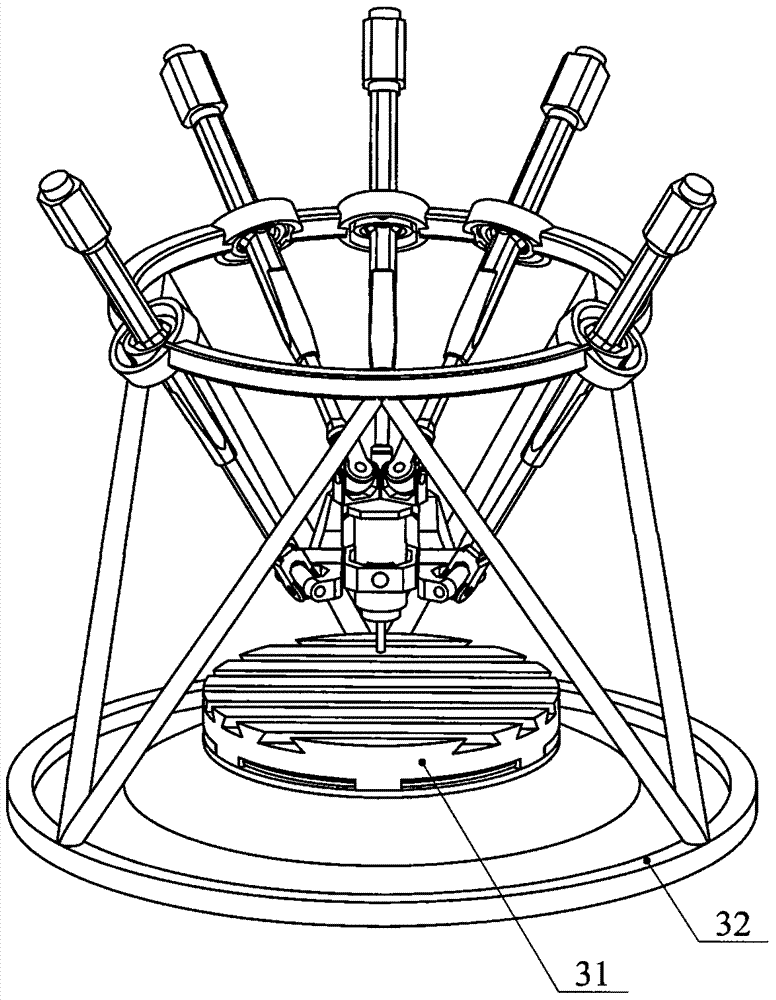

[0027] The structure of a multi-axis linkage device that can realize five-face machining in this embodiment is as follows: image 3 As shown, the multi-axis linkage device is different from Embodiment 1 in that: the multi-axis linkage device also includes a turntable 31 and a kinematic pair. There is one kinematic pair, which is a rotary pair connected between the fixed platform 32 and the turntable 31, and the rotary pair is driven. The device can realize six-axis linkage control of three moving degrees of freedom and three rotating degrees of freedom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com