Device for stacking and cutting peach slices

A cutting device and a technology for peach slices, which are applied in metal processing and other directions, can solve problems such as low efficiency and low production efficiency, and achieve the effects of improving efficiency, improving production efficiency, and speeding up the process of manual stacking and flattening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

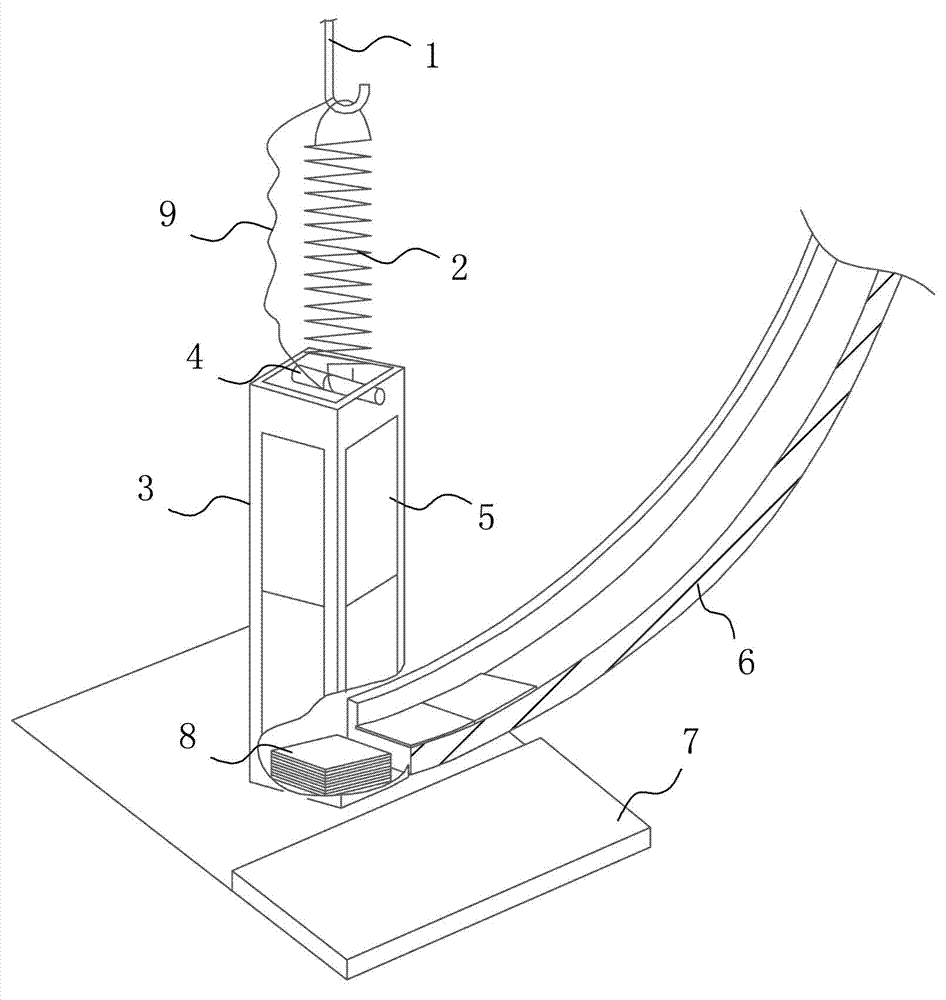

[0011] Such as figure 1 As shown, a device for stacking and cutting peach slices 8 includes a feeder 6, wherein the feed end of the feeder 6 is higher than the discharge end, and is also provided with a discharge table 7, a stacking box 3, a stacking table, and a cutting table. Knife 5, spring 2 and hook 1, the stacking box 3 has a rectangular cross section, the bottom of the stacking box 3 is provided with a stacking board, and the four side walls of the stacking box 3 are provided with a cutting knife 5 slidingly connected to the side wall; The discharge platform 7 is located below the stacking box 3, the discharge end of the material channel 6 is located on one side of the stacking box 3, the upper end of the spring 2 is hung on the hook 1, the lower end of the spring 2 is connected to the upper end of the stacking box 3 through a cross column 4, and the cross column 4 is two The end is fixedly connected to the upper end of the stacking box 3. In this embodiment, a slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com