A kind of true color embossed leather and its manufacturing method

A manufacturing method and true color technology, applied in chemical instruments and methods, textiles and papermaking, lamination, etc., can solve the problems of insufficient color patterns, single leather color, and only a few colors, etc., to achieve bright and novel visual effects, Good hand feeling and strong ink absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

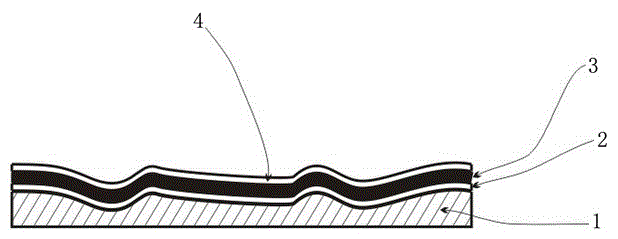

[0025] Such as figure 1 As shown, a kind of true-color embossed leather includes an embossed leather body 1 with a concave-convex undulating three-dimensional figure on the surface pressed by a three-dimensional mold, the upper surface of the embossed leather body 1 is coated with a colored layer 2, and A color ink layer 3 is spray-painted on the upper surface, and a wear-resistant layer 4 is coated on the upper surface of the color ink layer 3 .

[0026] The manufacture method of above-mentioned true color embossed leather, comprises the steps:

[0027] 1) Select a three-dimensional mold corresponding to the embossed pattern of the desired embossed leather;

[0028] 2) Place the leather under the three-dimensional mold, increase the temperature of the three-dimensional mold, increase the pressure of the three-dimensional mold, carry out high-temperature stamping, and cool and shape to obtain the embossed leather body;

[0029] 3) Spray the prepared leather inkjet colorant e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com