Double-station torque multiplier

A torque multiplier and double-station technology, which is applied in the direction of manufacturing tools, transmission parts, gear transmissions, etc., can solve the problems of large thread tightening torque, large thread specifications, and unusability, and achieve large torque and high safety factor , The effect of simplifying difficult tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with implementation examples.

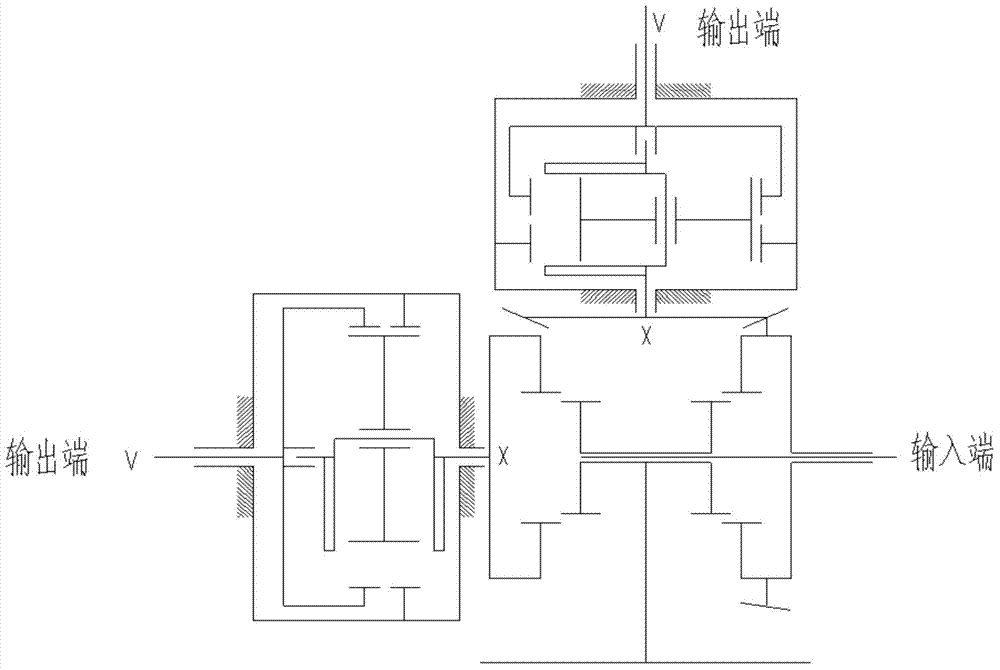

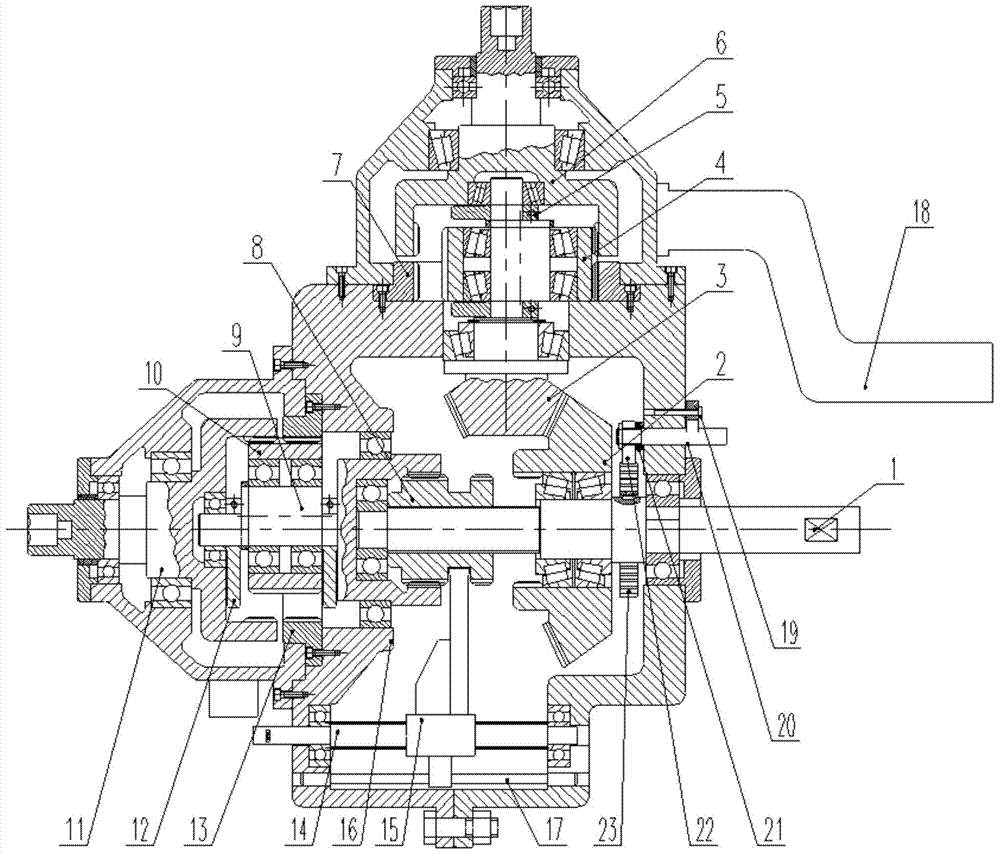

[0019] see figure 1 , figure 2 with image 3 , the frame housing 16 is provided with an input shaft 1, and the frame housing 16 is rotatably mounted with a transverse planet carrier 9 on the same axis as the input shaft 1 and a transverse output center wheel 11 and is fixedly mounted with the input shaft 1 at Horizontal fixed center wheel 13 on the same axis, one end of the transverse planetary carrier 9 is provided with internal teeth, the other end is provided with an eccentric shaft and a transverse balance weight 12, the transverse planetary wheel 10 is sleeved on the eccentric shaft of the transverse planetary carrier 9, and the transverse planetary The wheel 10 is meshed with the transverse fixed center wheel 13 and the transverse output center wheel 11 at the same time; the transverse planet carrier 9, the transverse p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap