Turning and downward pressing positioning mechanism

A technology of positioning mechanism and flip seat, applied in the direction of the casing of the measuring device, etc., can solve the problems of unbalanced force on the pressing part and damage to the electronic components, so as to avoid uneven force, balanced force, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0024] In the following description of the technical solution, the electronic component only takes the probe as an example. The flip-down positioning mechanism provided by the present invention is also suitable for other electronic components such as cables.

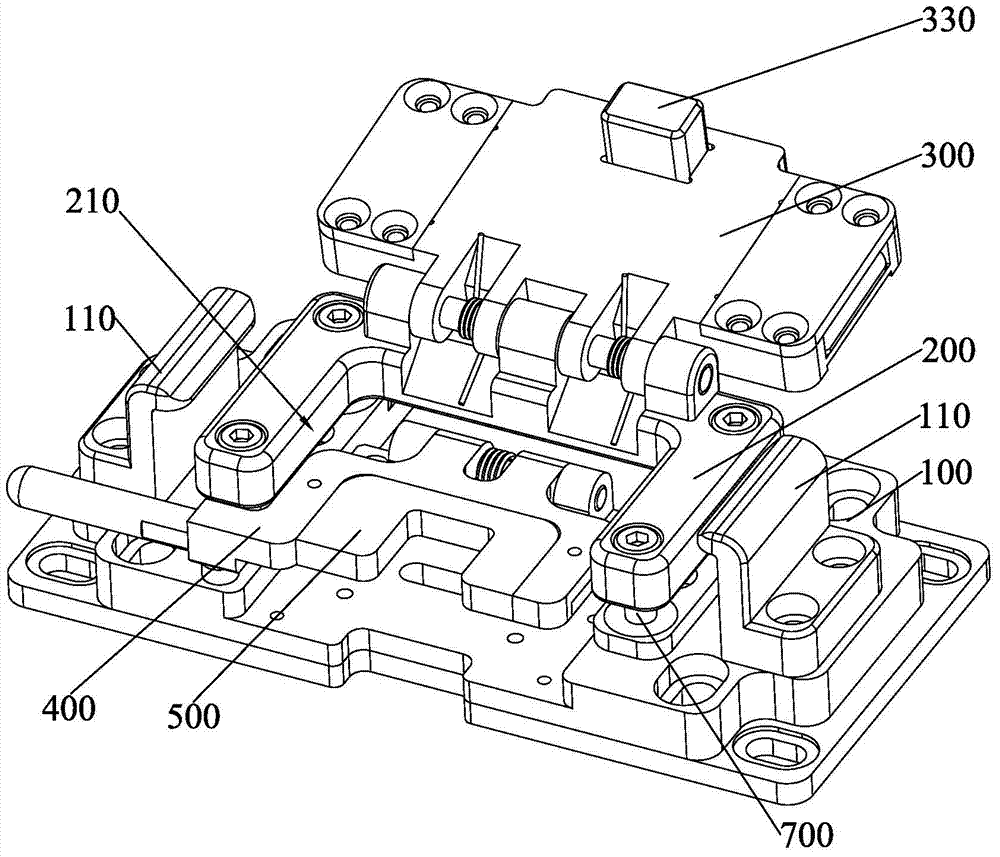

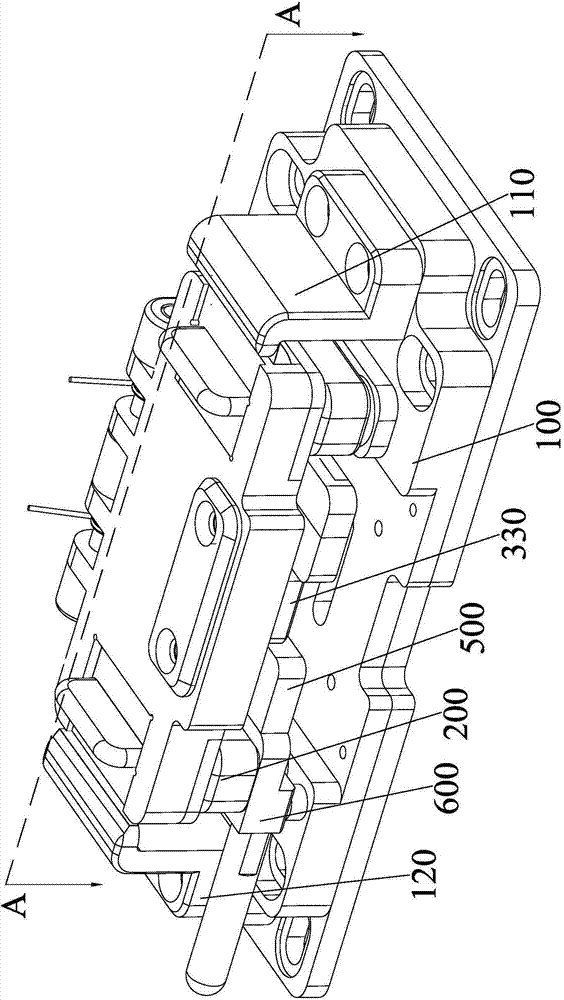

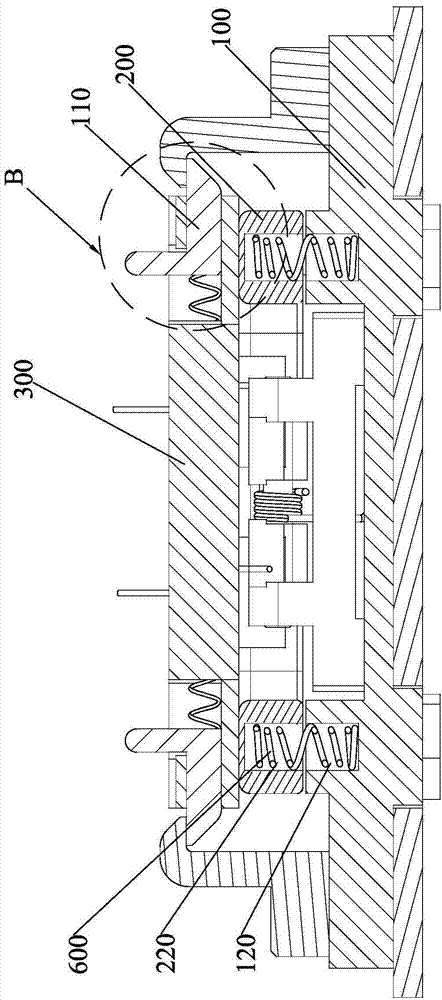

[0025] Such as figure 1 The turning down positioning mechanism shown includes a base 100 , a turning seat 200 , a turning piece 300 , a pre-pressing positioning piece 400 , and a probe positioning module 500 . The pre-pressing positioning member 400 is pivotally connected to the base 100 for positioning the probe positioning module 500; the flipping seat 200 is arranged above the base 100 to move up and down; one side of the flipping member 300 is pivotally connected to the The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com