Reversing valve element

A reversing valve and valve core technology, which is applied to fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of inconvenient use and operation, and the hydraulic reversing valve core cannot work normally, so as to save oil. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

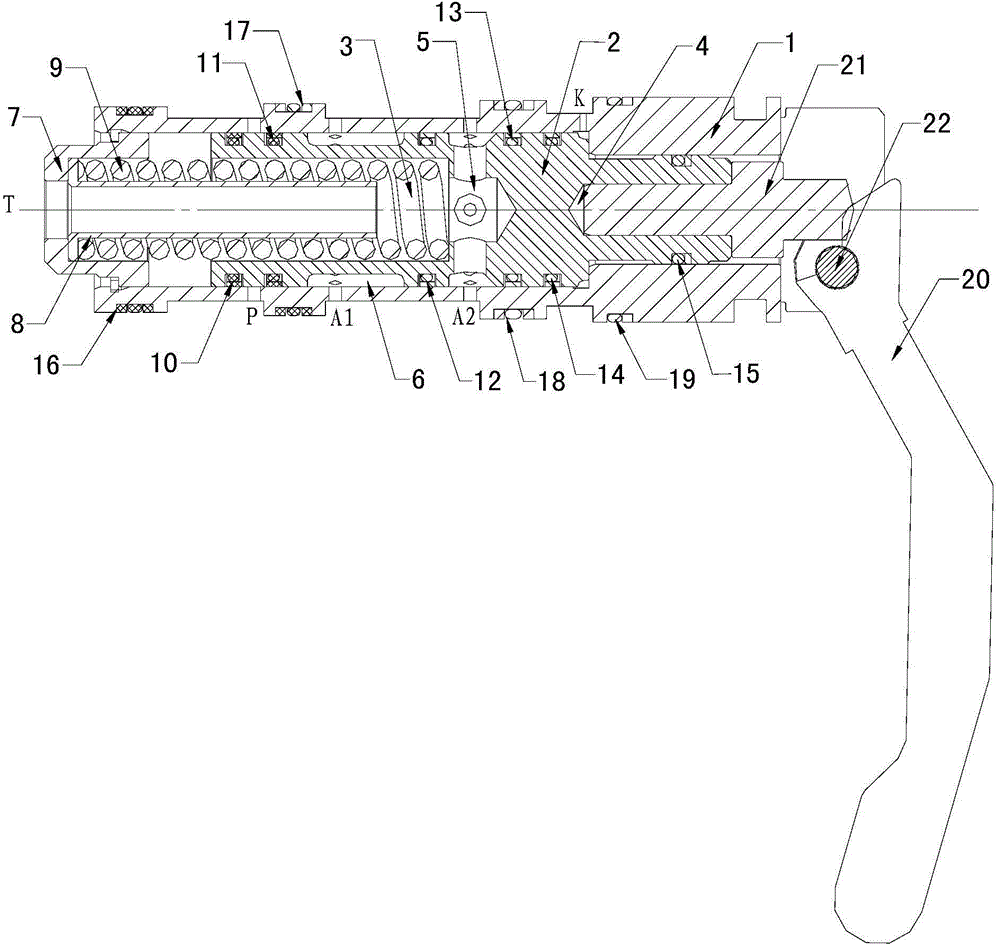

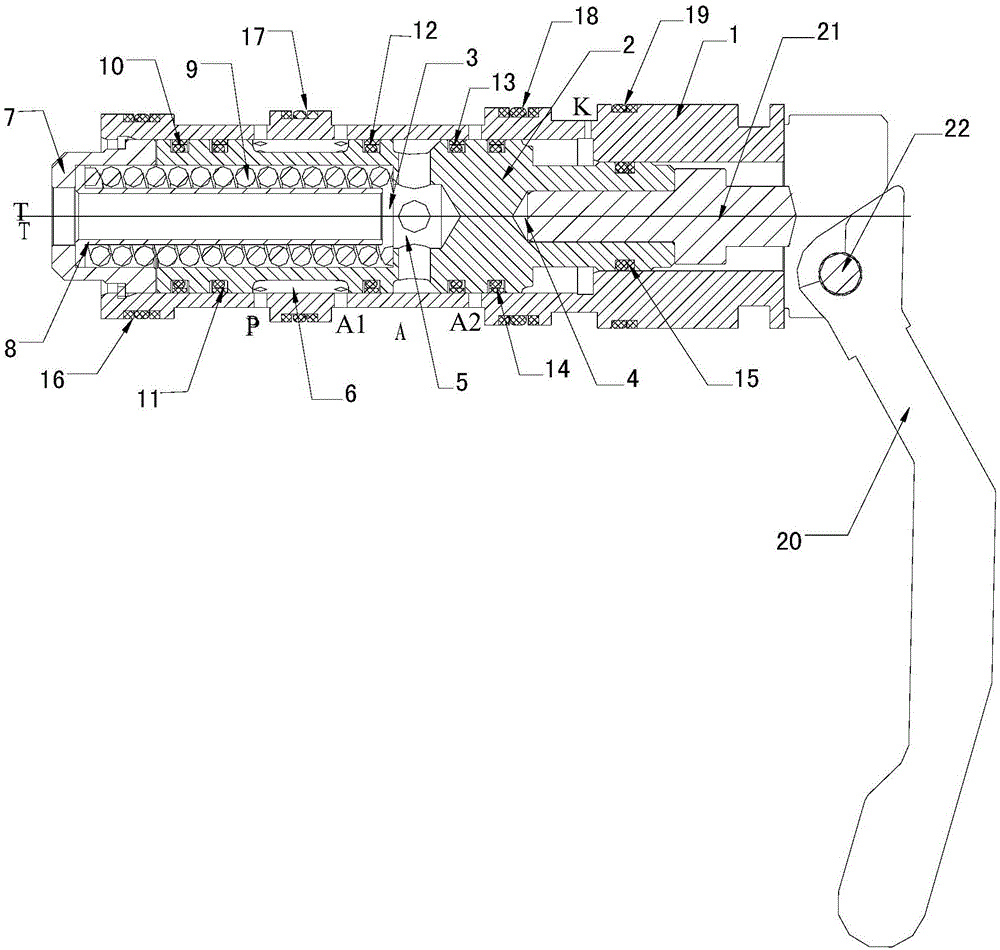

[0014] Embodiment: A reversing valve core, including a valve sleeve 1 and a valve stem 2, the valve stem 2 is located in the valve sleeve 1 and coaxially arranged with the valve sleeve 1, and the front part of the valve stem 1 is provided with a first concave cavity in the axial direction 3. The rear part of the valve stem 1 is provided with a second cavity 4 along the axial direction, the valve stem 1 is provided with a connecting hole 5 communicating with the first cavity 3, and the front end of the valve sleeve 1 is provided with a hole extending into the first cavity 3. The elastic reset device, the rear end of the valve sleeve 1 is provided with a handle assembly extending into the second cavity 4, the inside of the elastic reset device communicates with the first cavity 3, and the outer wall of the valve stem 2 is provided with an annular communication groove 6, Valve sleeve 1 is provided with pressure oil port P, first working oil port A1, second working oil port A2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com