Rice and wheat straw returning, rotary tillage, fertilization and seeding combined machine

A combined operation machine and rice-wheat straw technology, which is applied to agricultural machinery and tools, agriculture, shovels, etc., can solve problems such as difficult cleaning, soil accumulation on the casing, and grass entanglement on the cutter shaft, so as to achieve easy cleaning, not easy to accumulate soil, The effect of not being entangled with grass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

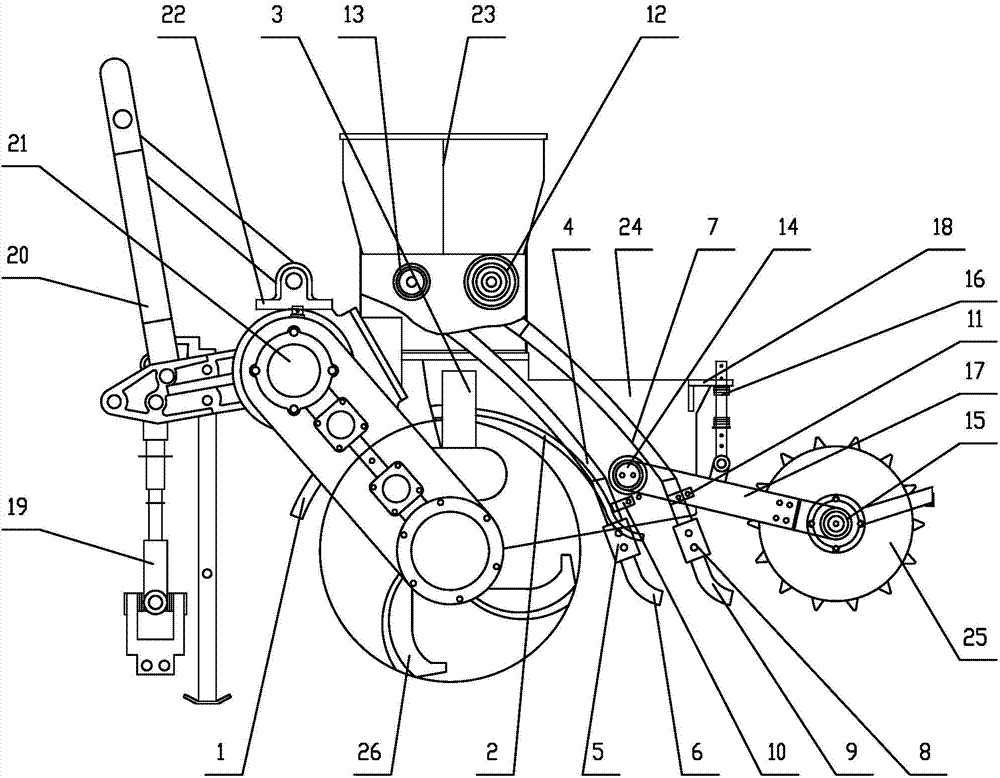

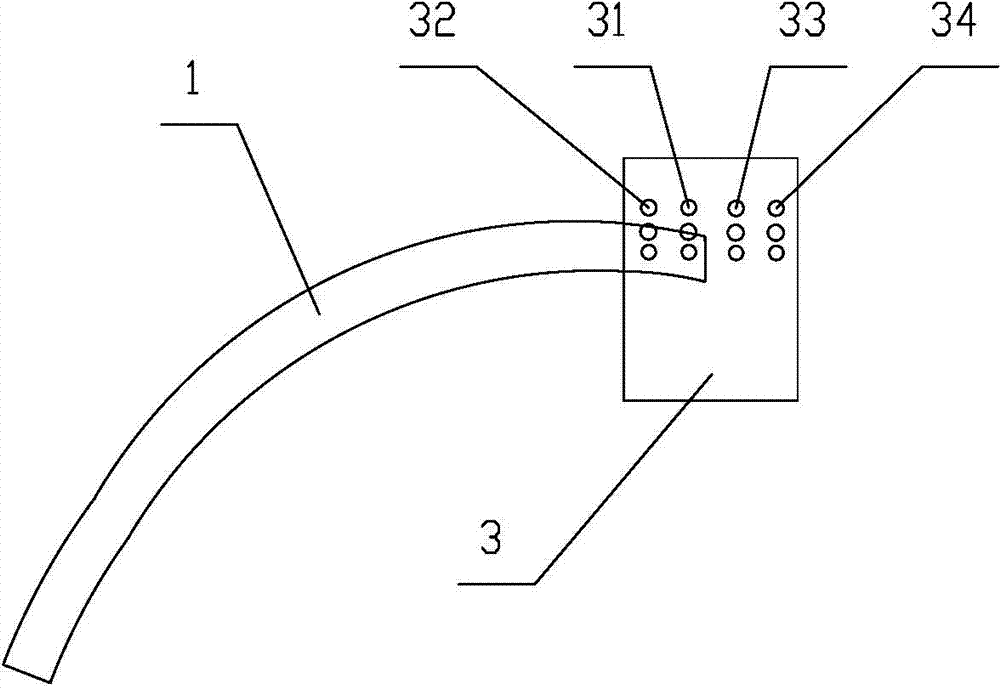

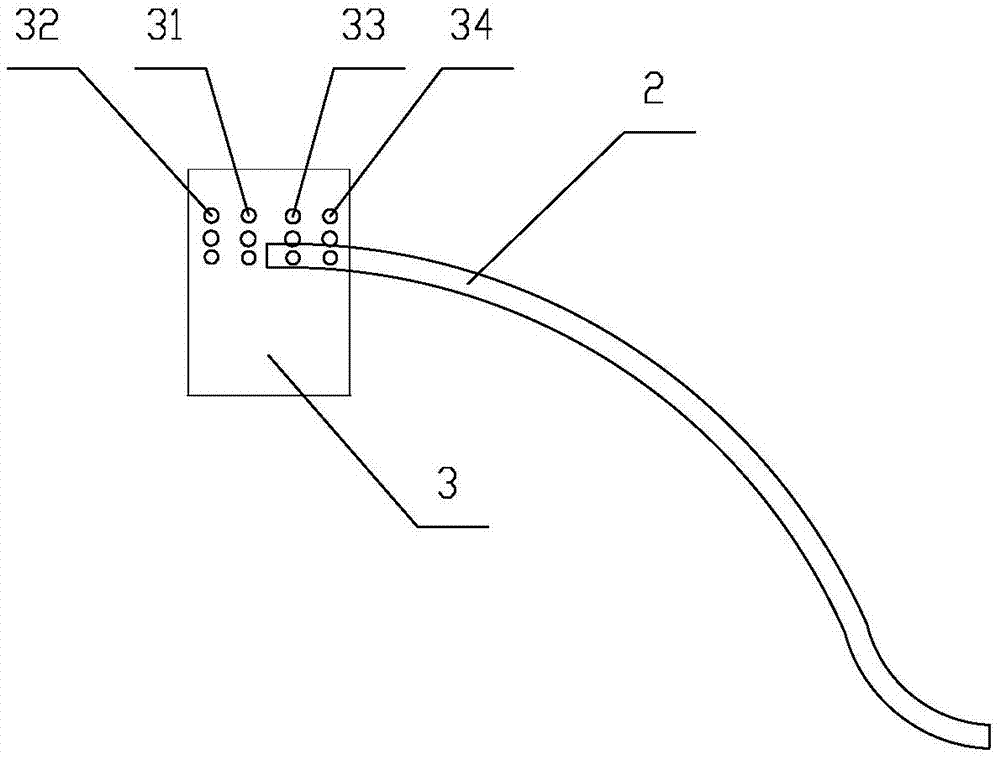

[0030] Such as Figure 1 to Figure 3As shown, the combined rice and wheat straw returning machine of the present invention includes a suspension assembly 20, the suspension assembly 20 is fixedly connected to the tractor, the power output device of the tractor is connected to one end of the universal joint assembly 19, and the universal joint assembly The other end of Cheng 19 is connected with the input end of the speed changer 22, the output end of the speed changer 22 is connected with the input end of the transmission device 21, and the output end of the transmission device 21 is connected with the shaft of the rotary tiller. Speed changer 22 and transmission device 21 are all installed on the frame. A bracing frame 3 is set above the rotary tiller 26, and the bracing frame 3 is fixedly connected with the frame. Four rows of bolt holes are set on the bracing frame 3, and each row has three bolt holes. The bolts connect the bolt holes on the casing 1 with the first row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com