Six-head spiral rotary tillage and stubble burying knife roller

A technology of rotary tiller and helical rotation, which is applied to the field of six-head helical rotary tiller, stubble and grass-burying knife roller, can solve the problems of high power consumption and increased power consumption of tractors, and achieves easy improvement, reduced power consumption, high power consumption, etc. Effects of straw crushing rate and burial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further explained:

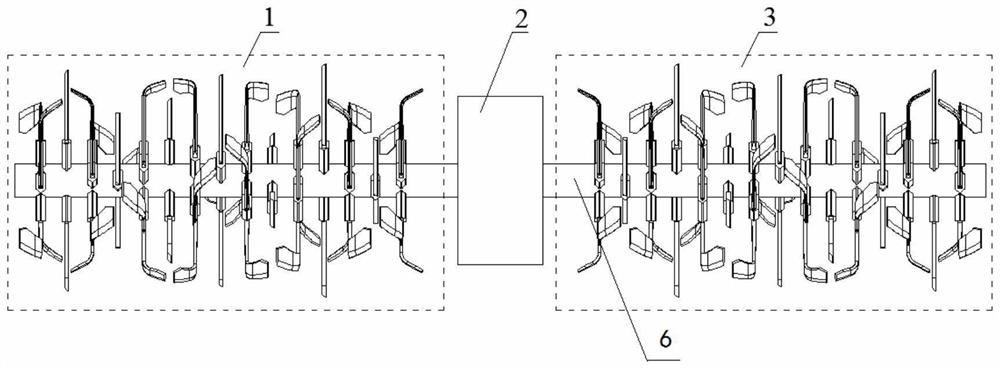

[0021] see figure 1 , the six-headed spiral rotary tillage and stubble burying knife roll (knife roll for short) is divided into a left knife roll 1 and a right knife roll 3 according to needs in actual use, and the two structures are symmetrically arranged, and the knife on the right knife roll 3 Arranged in a right-handed helix, the knives on the left knife roller 1 are arranged in a right-handed helix, the helix has a rise angle of 5°±1°, and a lead of 3m-3.3m. During installation, the left and right knife rollers 1, 3 are respectively connected to the output shafts on both sides of the gearbox 2.

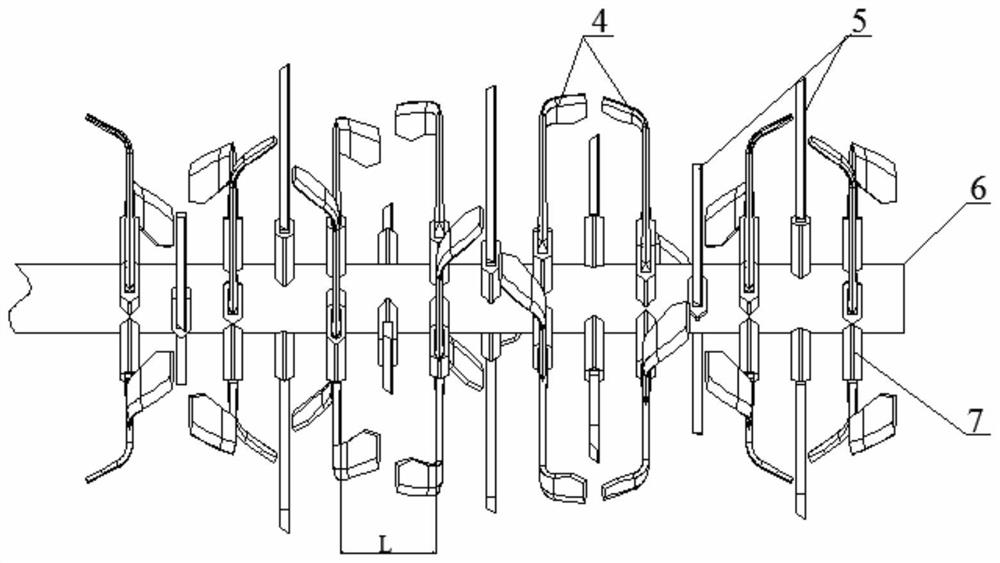

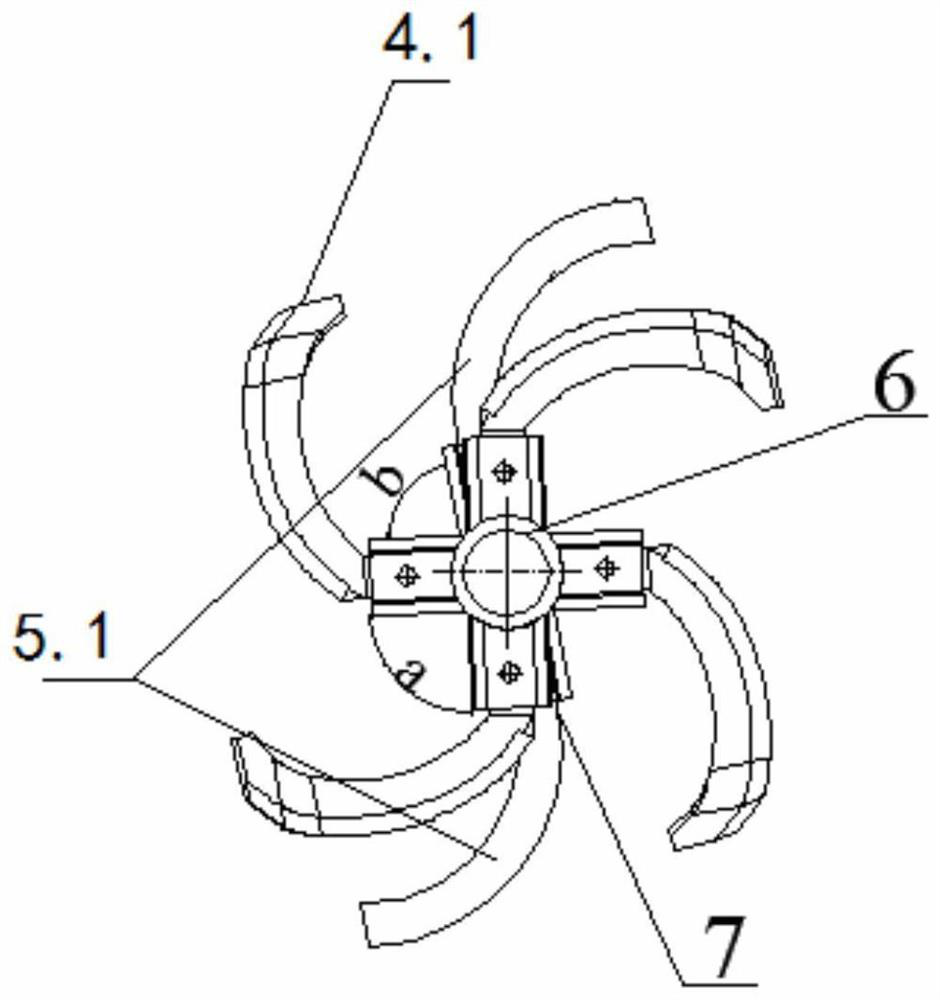

[0022] The knife roll of the present invention illustrates its structure by taking the right knife roll as an example. figure 2 , including the cutter shaft 6, a plurality of sets of rotary blade groups 4 arranged in a right-handed helical manner along the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com