Test tube rack with locking function

A test tube rack, test tube technology, applied in the direction of test tube brackets/clamps, etc., can solve problems such as instability, need to be inclined at a large angle to enter, rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

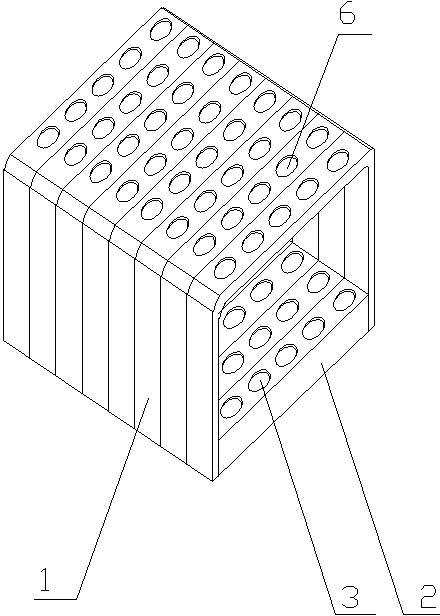

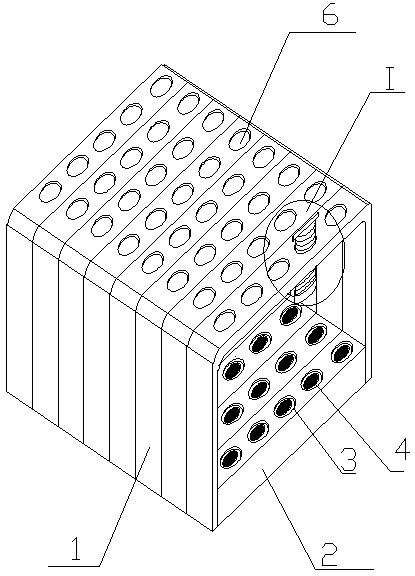

[0027] as attached figure 2 As shown, the test tube rack with locking function is composed of a test tube frame 1 and a test tube support seat 2, the test tube support seat 2 is located at the bottom of the test tube frame 1, and several rows and rows of guide holes 3 are uniformly provided on the test tube support seat 2 . The guide hole has a built-in guide column 4 and the first spring 5, and its structure is shown in the attached Figure 4 shown. The first spring 5 is located at the bottom of the guide hole 3 , and the guide post 4 can freely move up and down in the guide hole 3 under the action of the first spring 5 .

[0028] as attached figure 2 As shown, the top panel of the test tube frame 1 is provided with a through hole 6 corresponding to the guide hole. The through hole 6 and the guide hole 3 are located on the same vertical axis, and the through hole 6 is provided with a test tube locking device.

[0029] For the locking device on the through hole 6 see ...

Embodiment 2

[0035] The test tube rack with locking function provided in this embodiment has the same structure except that the locking device is different from that in Embodiment 1.

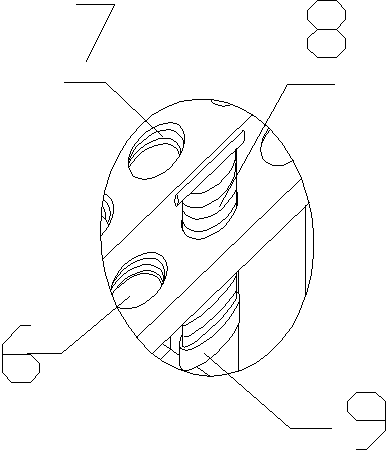

[0036] as attached Figure 5 shown at II in , for clarity, appended Figure 5 shows a locking device on a through hole, combined with the attached Figure 6 As shown, it should be understood that each through hole 6 is provided with the same locking device.

[0037] as attached Figure 5 , attached Figure 6 , attached Figure 7 and attached Figure 8 As shown, the locking device is a self-locking mechanical switch. The self-locking mechanical switch includes a cylindrical housing 10 fixed on the top panel of the test tube frame. The housing is provided with a top cover 11 and a bottom plate 12 .

[0038] as attached Figure 6 As shown, the through hole 6 is pressed by the bottom plate 12 of the cylindrical shell and is located on the same vertical axis as the cylindrical shell.

[0039] as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com